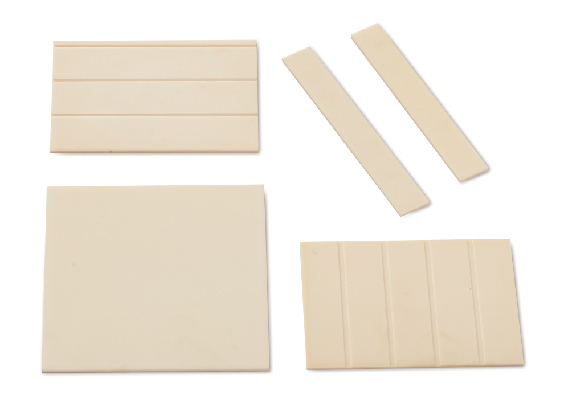

99% Alumina Ceramic Trays For Powder MIM (Metallurgy Injection Moulding)

Product Features

Our 99% Alumina Ceramic Trays exhibits outstanding resistance to thermal shock and high-temperature creep, with high density and no volatilization of other impurities. It has a long service life, a delicate product surface, high strength, and is resistant to deformation.

Application Scope

Our 99% Alumina Ceramic Tray is characterized by excellent resistance to thermal shock and high-temperature creep, high density, and no volatilization of other impurities. It has a long service life, a delicate product surface, high strength, and is resistant to deformation.

Suitable for MIM (Metallurgy Injection Moulding) stainless steel sintering.

Technical Parameters

| Al2O3(%) | 99.0 |

| Fe2O3(%) | < 0.03 |

| MgO (%) | 0.25 |

| Na2O(%) | <0.016 |

| Vickers Hardness (Gpa) | 14.5 |

| Flexural Strength (Mpa) | 320 – 340 |

| Fracture Toughness (Mpa√m) | 2.0 – 2.5 |

| Temperature Limit (˚C) | 1650 |

| Thermal Expansion Rate x 10-6 at 1000 ˚C | 7.6 |

| Dielectric Strength (Kv/mm) | 10.0 |

| Bulk Density (g/cm3) | 3.90 |