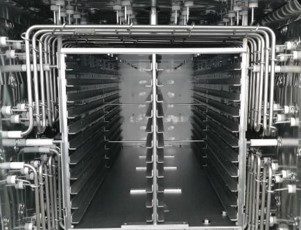

Debinding and Sintering Furnace

Product Features

Introducing our state-of-the-art Full Series Debinding and Sintering Furnace:

- Metal Injection Molding (MIM): Advanced technology for efficient metal part production.

- Additive Manufacturing (AM): Catering to the latest in 3D printing and rapid prototyping.

- Cemented Carbide (WC): Ideal for hard material production.

- Heat Treatment (HT): Ensuring the durability and longevity of metal products.

Technical Highlights

- Graphite Hot Zone Debinding: Innovative technology ensuring improved yield of MIM products.

- AI.SmartSinter: Automated sintering process calculations using AI for enhanced reliability and accuracy.

- Walking Beam Continuous Furnace: High productivity with debinding and sintering combined, ideal for large quantity productions.

Technical Specifications

| Retort Size | 200 x 200 x 200 mm |

| Max Temperature | 1600°C |

| Operation Temperature Range | 1450 – 1500°C |

| Temperature Distribution | ±4°C (±2°C) |

| Ultimate Vacuum | 20 to 9 x 10-3 Pa (option) |

| Power Capacity | 30 to 35 KVA |

| Gas Options | N2, Ar, H2 (option) |

| Equipment Size | 1.4 x 0.9 x 1.77 m3 |