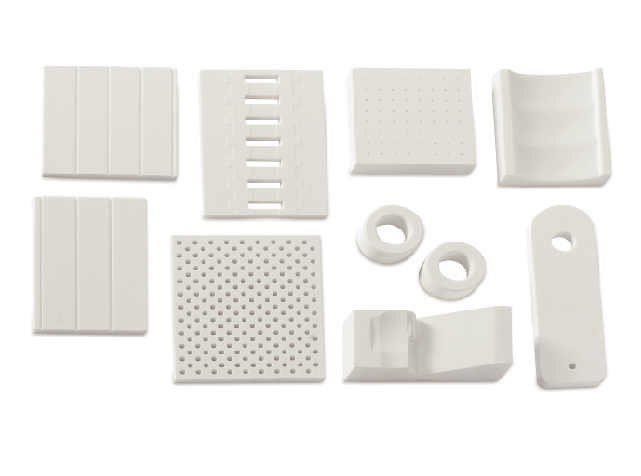

Exploring Corundum Mullite Sintering Trays: The Premier Choice for High-Temperature Applications

In high-temperature sintering environments, selecting the appropriate sintering tray material is crucial to ensure process efficiency, product quality, and operational durability. Among the materials used for this purpose, corundum-mullite has become an excellent choice, especially under harsh thermal and chemical conditions. This blog post delves into the characteristics, advantages, and industrial applications of corundum-mullite sintering trays and explores why they are becoming increasingly popular across various fields.

Understanding Corundum-Mullite

Corundum-mullite is a composite ceramic material that combines the high thermal stability of alumina (corundum) with the excellent thermal shock resistance of mullite. This synergistic combination allows the material to not only withstand extremely high temperatures but also offers remarkable durability and strength.

Key Properties:

- High-Temperature Stability: Corundum-mullite can effectively operate at temperatures up to 1700°C, making it suitable for high-temperature sintering processes.

- Outstanding Thermal Shock Resistance: The material can withstand sudden temperature changes without cracking, which is invaluable for applications involving rapid heating and cooling cycles.

- Chemical Inertness: Corundum-mullite is resistant to chemical corrosion, not reacting with most molten metals, salts, or acidic or alkaline environments, ensuring the purity and integrity of the sintered products.

- Mechanical Strength: It possesses excellent mechanical strength and wear resistance, which is crucial for operations and durability in harsh industrial environments.

Advantages of Corundum-Mullite Sintering Trays

Improved Product Quality:

Using corundum-mullite trays during sintering minimizes the risk of contamination from inert materials. This is particularly important in industries where product purity is critical, such as in the manufacture of advanced ceramics and metallurgical powders.

Durability and Cost-Effectiveness:

While corundum-mullite trays may have a higher initial cost compared to other materials, their long service life and wear resistance reduce the frequency of replacements and downtime. In the long run, this durability makes them a cost-effective choice.

Versatility:

The robustness of corundum-mullite under high temperatures and rapid thermal cycles makes it suitable for a variety of sintering processes. This includes, but is not limited to, the sintering of technical ceramics, heavy clay products, and firing steps in electronic component manufacturing.

Industrial Applications

- Technical Ceramics: In the production of technical ceramics such as zirconia and silicon nitride, corundum-mullite trays provide the necessary thermal performance to achieve high-density and high-strength final products.

- Electronics Industry: For the electronics industry, particularly in the manufacturing of semiconductor devices and electronic ceramics, corundum-mullite trays ensure precise control and uniformity during the heat treatment process.

- Metallurgy: Corundum-mullite is also used in powder metallurgy and the sintering of complex metal parts, where its thermal shock resistance and mechanical strength provide significant advantages.

Conclusion

Corundum-mullite sintering trays are the optimal solution for industries that require high-performance, durable, and chemically inert components in high-temperature sintering processes. These trays offer outstanding performance and adaptability, not only improving the efficiency of the sintering process but also significantly enhancing the quality of the final products. As technological advancements continue to drive the demand for high-temperature materials, corundum-mullite has become a reliable and effective choice for modern sintering applications.

Leave a Reply