Comparison of Mullite and Other Refractory Materials

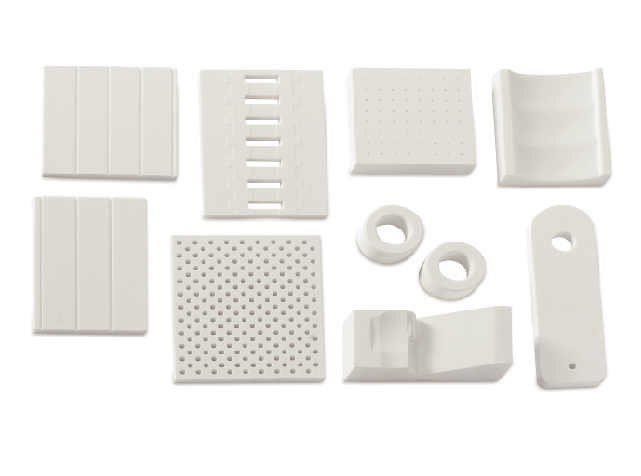

Selecting the right refractory material for high-temperature applications is crucial, as material performance, cost, and environmental conditions play a significant role. Mullite (3Al₂O₃·2SiO₂) is widely used in metallurgy, ceramics, and the glass industry due to its excellent high-temperature performance and strength. This article provides a detailed comparison of mullite with other common refractory materials, such as aluminosilicate and alumina, to help readers make informed decisions.

1. Refractory Performance

Refractory performance is one of the most critical indicators of a material’s suitability. Mullite has a melting point typically above 1700°C, making it highly stable at extreme temperatures. Its high melting point makes it an ideal choice for applications in smelting furnaces, heating equipment, and ceramic kilns.

- Aluminosilicate: The refractory temperature of aluminosilicate is generally around 1400°C, suitable for medium to low-temperature applications. Aluminosilicate has good thermal insulation properties but can soften at high temperatures, leading to structural instability. Therefore, it requires caution when used under high temperature or high load conditions.

- Alumina: Alumina’s refractory temperature is similar to that of mullite, typically around 1700°C. However, its performance may be affected by impurities, which can impact its overall effectiveness.

2. Mechanical Strength

Mullite has excellent mechanical strength, capable of withstanding substantial loads and pressure. Its compressive and flexural strengths rank among the best in refractory materials, making it suitable as a lining material for high-temperature kilns.

- Aluminosilicate: While its strength is relatively lower, it is still acceptable in certain applications. Due to its tendency to soften at high temperatures, aluminosilicate can become unstable under high load conditions, particularly during thermal cycling.

- Alumina: Alumina has mechanical strength comparable to mullite, but it is more brittle and prone to fracture under impact or vibration. This brittleness can be a potential drawback in high-stress applications.

3. Cost Considerations

Cost is an essential factor when selecting refractory materials. The production process of mullite is relatively complex, involving high-temperature sintering and precise material composition, which typically results in higher costs. This could be a barrier for budget-sensitive projects.

- Aluminosilicate: Due to its simpler production process and easy availability of raw materials, aluminosilicate is typically more affordable. This makes it an ideal choice for large-scale applications, particularly in construction and insulation materials.

- Alumina: The cost of alumina lies between that of mullite and aluminosilicate, making it suitable for moderately budgeted projects. When selecting alumina, one must consider the balance between its overall performance and cost.

4. Chemical Stability

Chemical stability is another critical indicator of refractory materials, especially in industries like chemicals and metallurgy, where materials are frequently exposed to acids, bases, and molten metals.

- Mullite: Mullite has excellent chemical stability, resisting a wide range of acids, bases, and molten metals. This makes it suitable for use in chemically corrosive environments, making it ideal for high-corrosion applications.

- Aluminosilicate: Although aluminosilicate is generally chemically stable, it may be affected in certain acidic environments, which can lead to a decline in performance. Therefore, its suitability must be carefully assessed under specific conditions.

- Alumina: Alumina performs well in most chemical environments but may react under extreme conditions. In high-temperature situations, certain chemical components may react with alumina, potentially reducing its performance.

5. Application Scenarios

The choice of refractory material is often closely related to its specific application scenario.

- Mullite: Primarily used in high-temperature environments such as smelting furnace linings, sintering kilns, and glass furnaces. Its high temperature and strength make it an excellent choice for these industries.

- Aluminosilicate: Widely used in industrial kilns, casting applications, thermal insulation materials, and refractory bricks. Its low cost and good thermal insulation properties make it ideal for large-area coverage.

- Alumina: Suitable for glass furnaces, steel production, and certain chemical equipment, particularly applications requiring resistance to chemical corrosion.

6. Conclusion

When selecting refractory materials, it is essential to consider factors such as refractory performance, mechanical strength, cost, chemical stability, and specific application scenarios. Mullite offers distinct advantages in high-temperature, high-strength environments and is ideal for demanding industrial applications. Aluminosilicate and alumina perform well under specific conditions and budget constraints, making them suitable for other applications.

Leave a Reply