MIM Feedstock

Product Features

Each feedstock comes with a unique set of features designed for optimal performance. The tool must be designed with flow paths as short and as thick as possible. The shrinkage which arises during processing must be considered by oversizing the mold dimensions.

Application Scope

These feedstocks are suitable for various industrial applications requiring high precision and durability. They are ideal for sectors like automotive, aerospace, and medical equipment manufacturing.

Technical Parameters

The feedstock processing for various materials like 17-4PH, 304L, 316L, 420W, 440C, and 4140 is meticulously outlined in our guidelines. Each material is subject to specific protocols to ensure optimal results.

| Feedstock: 17-4PH, 304L, 316L, 420W, 440C, 4140, 4340, 4605, 8620, FeNi2 and more |

|||

|---|---|---|---|

| Processing Step | Description | Temperature Range (°C) | |

| Tool Design | Engineered with short, robust flow paths. Molds are intentionally oversized to account for shrinkage. | N/A | |

| Injection | Specific injection parameters are set for each material to ensure optimal flow and filling. | 200-250 | |

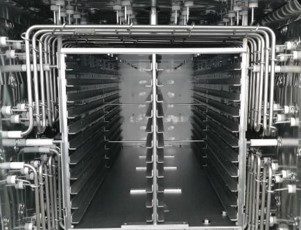

| Debinding | Debinding process is fine-tuned for each material to remove the binder effectively. | 300-400 | |

| Sintering | Sintering conditions are optimized for each material to achieve desired mechanical properties. | 1200-1400 | |