Reaction Sintered Silicon Carbide Plate [MM-XG-SiC95]

Product Features

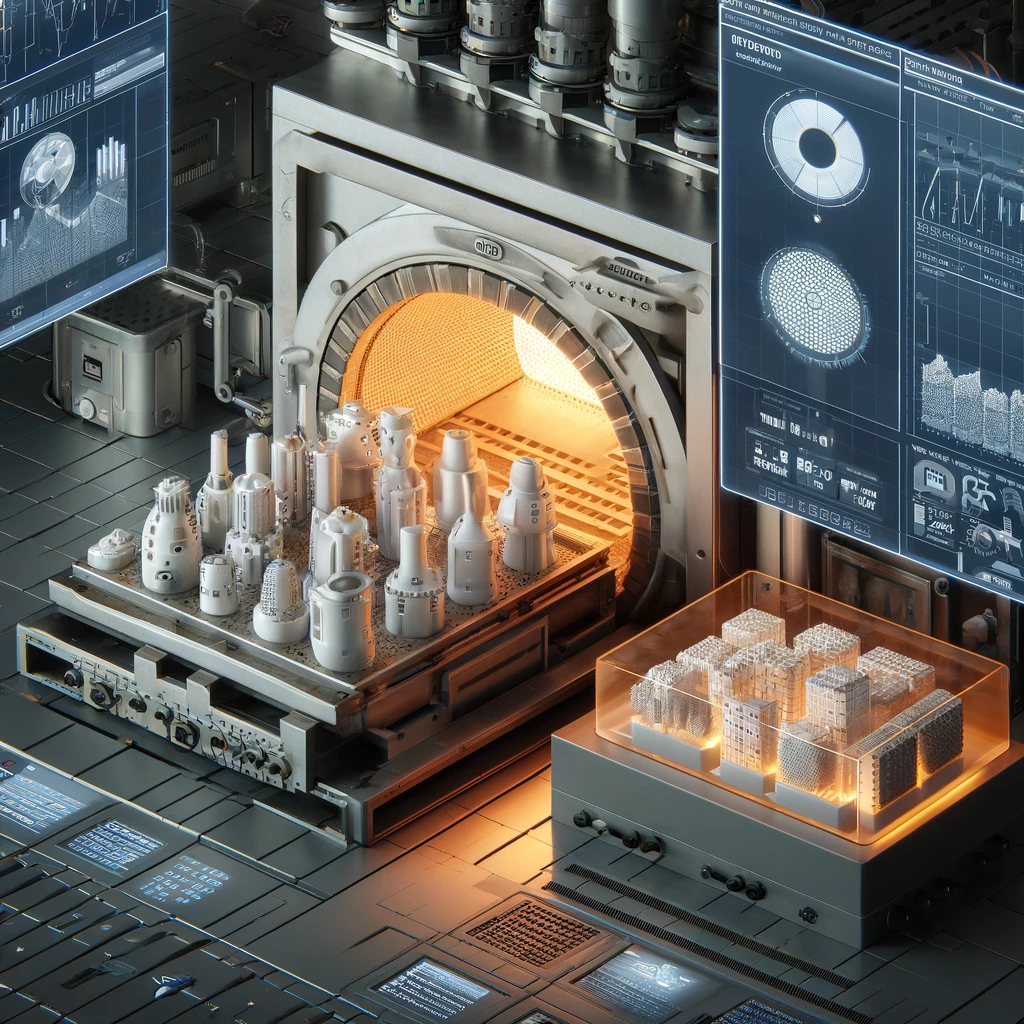

Introducing our high-performance Reaction Bonded Silicon Carbide (RBSiC) shelves, specifically designed for high-temperature industrial applications:

- Exceptional High-Temperature Resistance: Engineered to withstand temperatures below 1400°C while maintaining structural integrity, making them ideal for high-temperature processes like kilns and furnaces.

- Thermal Shock Resistance: Provides excellent resistance to rapid temperature changes, ensuring durability in demanding industrial environments that experience frequent heating and cooling cycles.

- Durability and Wear Resistance: With a hardness of 2400 Kg/mm² and high structural strength, these shelves offer a long service life, even under tough and abrasive conditions, ensuring cost-effective and reliable performance.

Applications

Reaction Bonded Silicon Carbide shelves are ideal for:

- Kiln Furniture: Widely used in high-temperature kilns for industries such as ceramics and glass manufacturing.

- Industrial Heat Treatment: Suitable for applications requiring strong, durable support materials in high-temperature environments.

- Metallurgy: Perfect for use in metal processing industries where wear and heat resistance are critical.

Technical Highlights

- High Flexural Strength: Boasting a high-temperature flexural strength of 290 MPa at 1200°C, these shelves provide excellent mechanical stability, making them ideal for supporting heavy loads in high-temperature environments.

- Efficient Thermal Conductivity: At 1200°C, the shelves have a thermal conductivity of 45 W/m•K, ensuring effective heat management and uniform temperature distribution across the surface.

- Low Thermal Expansion: The thermal expansion rate is controlled at 4.5 x 10⁻⁶ at 1000°C, ensuring dimensional stability, minimizing risks of warping or cracking during thermal cycling.

Technical Specifications

| Parameter | Value |

|---|---|

| SiC Content (%) | ≥95 |

| Si Content (%) | ≤5 |

| Thermal Expansion Rate (x10⁻⁶ at 1000°C) | 4.5 |

| Hardness at 20°C (Kg/mm²) | 2400 |

| Thermal Conductivity at 1200°C (W/m•K) | 45 |

| High Temperature Flexural Strength (1200°C•0.5h) (MPa) | 290 |

| Suggested Working Temperature (°C) | <1400 |

| Open Porosity (%) | <0.1 |

| Bulk Density (g/cm³) | 3.07 |