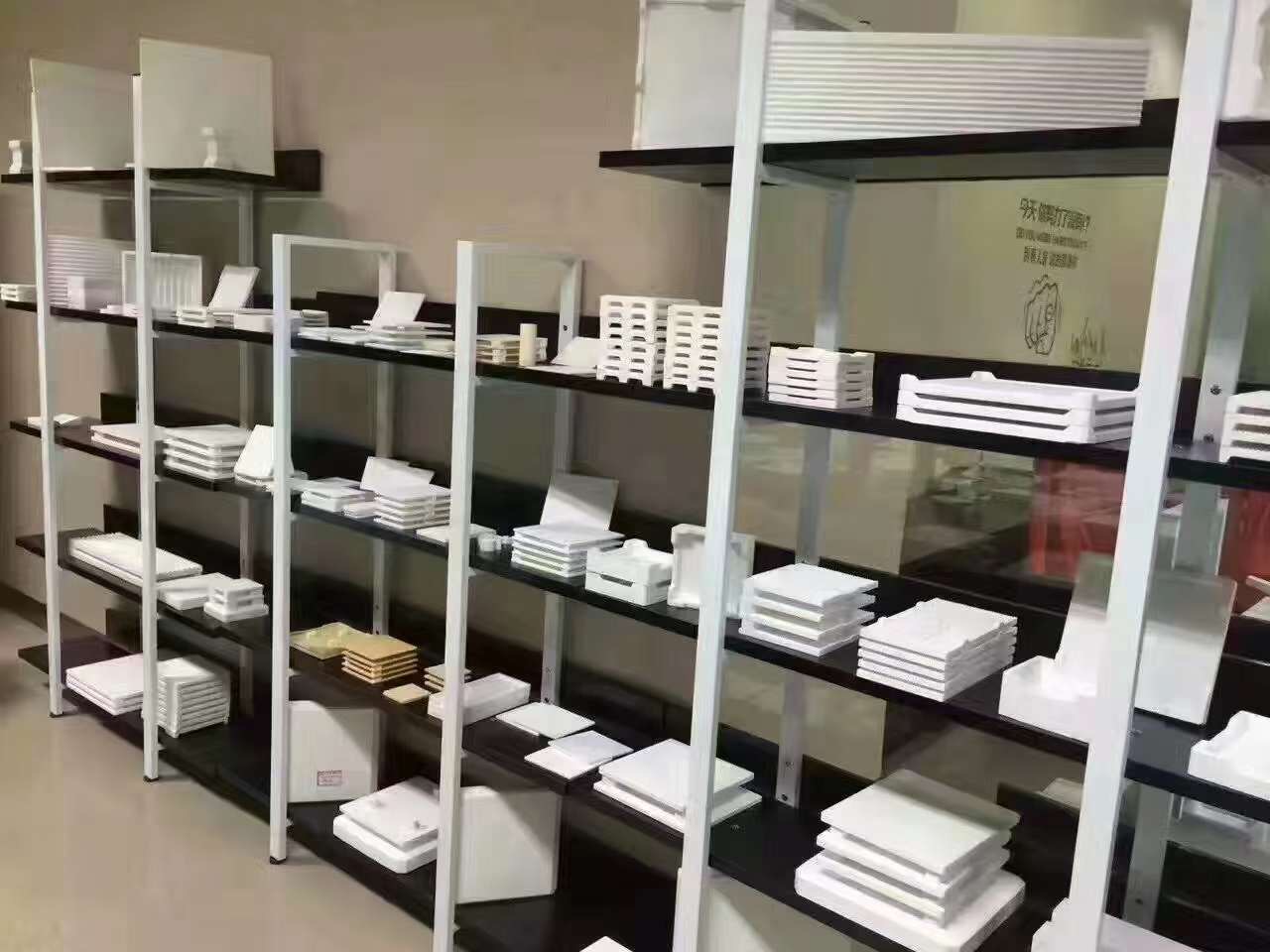

Corundum Mullite Saggers for Calcination Of 5n Alumina, Indium Oxide Ceramic Powder

Product Features

Our Corundum Mullite Saggers are expertly crafted for the precise calcination of high-purity alumina powder. Fired at an intense 1800℃, these saggers are constructed from 99.9% high-purity alumina (Al2O3) and premium low-sodium white corundum.

With a binder boasting an exceptionally low ash content (≤ 0.01%), we prioritize meticulous control over raw materials. This ensures minimal impurities and optimal high-temperature firing, stabilizing the Al2O3 activity. The result? A saggar with a minimal thermal expansion coefficient and unparalleled chemical purity, perfect for calcining top-grade ceramic powders. Moreover, the sagger’s efficient pore structure facilitates the siphoning effect during low-temperature calcination, ensuring comprehensive and effective organic matter removal.

Application Scope

- Use: High-purity ceramic powders calcination

Technical Parameters

| Value | |

| Al2O3(%) | 89.35 |

| SiO2 (%) | 10.45 |

| Fe2O3(%) | 0.06 |

| NaO+KaO (%) | ≤0.15 |

| Suggested Working Temperature (˚C) | 1650 |

| Thermal Expansion Rate x 10-6 at 1000 ˚C | 5.6 |

| Water Absorption Rate (%) | 23.00 |

| Bulk Density (g/cm3) | 2.95 |