Zirconia Teeth Manufacturing: Showcasing Moat City's Sintering Expertise

1. Introduction to Zirconia in Advanced Dental Prosthetics:

At Moat City, we have honed our expertise in zirconia sintering, a pivotal process in modern dental restoration. This article delves into our refined approach to transforming zirconia into exemplary dental prosthetics, highlighting the intersection of precision engineering and dental science.

2. The Significance of Zirconia in Dentistry:

Zirconia’s integration into dental practice has marked a significant advancement in restorative and cosmetic dentistry. Recognized for its robustness and visual similarity to natural teeth, zirconia at Moat City undergoes an optimization process to enhance its biocompatibility and resistance to wear. This makes it an ideal choice for various dental restorations, offering both functional reliability and aesthetic appeal.

3. The Comprehensive Manufacturing Process of Zirconia Teeth:

a. Design and Modeling:

- Accurate digital impressions are captured using advanced imaging technologies, forming the basis for CAD software-based precision designs.

b. Milling and Crafting:

- Zirconia blocks are intricately carved into the designed shapes using CAM techniques, with water cooling to maintain structural integrity.

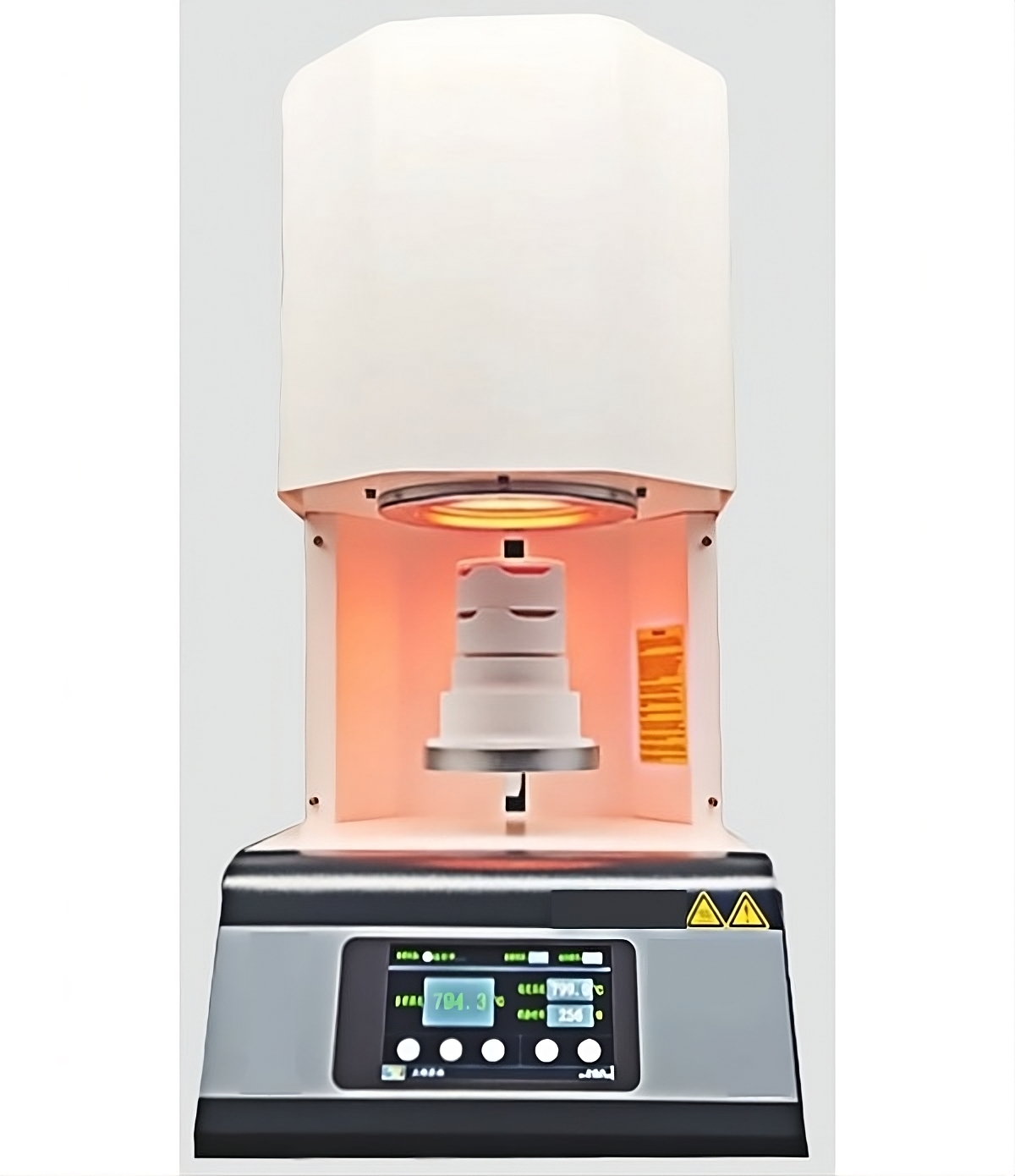

c. Sintering Process by Moat City:

- Employing high-temperature sintering techniques, we utilize specialized corundum-mullite plates and saggers for optimal densification and strength of the zirconia.

d. Coloring and Finishing:

- Custom coloring and glazing are applied to ensure each zirconia restoration matches the natural appearance of teeth.

4. Moat City’s Advanced Sintering Process:

At Moat City, the sintering process is a fusion of art and precision. Key aspects include:

- Our specially designed corundum-mullite plates facilitate even heat distribution, essential for the purity and consistency of the zirconia discs.

- For individual tooth sintering, we use corundum-mullite saggers, ensuring each tooth achieves ideal densification and structural integrity.

- The integration of advanced thermal monitoring and control systems guarantees that each zirconia product is sintered under the ideal conditions for maximum strength and longevity.

5. The Superiority of Moat City’s Zirconia Products:

Our zirconia dental prosthetics are distinguished by their long-lasting nature and aesthetic harmony with natural teeth. The meticulous sintering process endows these prosthetics with exceptional strength, making them ideal for a variety of dental restorations. Beyond strength, our focus on customization and precision ensures that each prosthetic is uniquely suited to the patient’s requirements, guaranteeing both comfort and functionality.

6. FAQs on Moat City’s Zirconia Sintering Process:

- Q: How does the sintering temperature impact zirconia’s properties?

A: The high sintering temperature is essential for enhancing the strength and durability of zirconia, making it suitable for dental applications. - Q: What factors contribute to zirconia’s enhanced durability?

A: Zirconia’s inherent fracture toughness, combined with our precision sintering process, results in a material that is exceptionally resistant to wear and tear. - Q: Are post-manufacture adjustments to zirconia restorations possible?

A: While zirconia allows for minor adjustments, its hardness limits extensive modifications. Our precision sintering aims to minimize the need for such alterations. - Q: Is Moat City engaged in ongoing research to enhance zirconia for dental use?

A: Yes, we are actively involved in research to continually improve the properties and efficiency of zirconia for dental applications.

7. Connect with Moat City for Advanced Sintering Solutions:

For further information on our zirconia sintering processes and products, please contact Moat City. We are committed to providing top-tier dental sintering solutions.

Email: rongqi.chen@moatcity.com

Web: www.moatcity.com

WhatsApp: +447983626714

Leave a Reply