Why Do Your Furnace Setters/ Kiln Push Trays Crack

Introduction: Navigating the Challenges of Furnace Setter Cracking

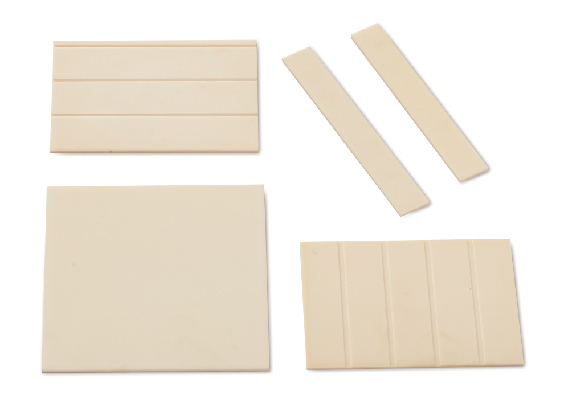

Ceramic kiln furniture, particularly furnace setters, plays a critical role in the production of ceramics, but they are prone to a common and troublesome issue: cracking. Understanding why furnace setters crack is crucial for maintaining the integrity and efficiency of the ceramic production process. This blog post explores the underlying causes of these cracks and provides practical guidance on how to prevent them.

Key Factors Influencing Furnace Setter Cracking

The longevity and performance of furnace setters in ceramic kiln furniture are heavily influenced by the chosen material’s properties and the environmental conditions during operation. The main factors contributing to furnace setter cracking are:

a. Thermal Shock Resistance:

- Understanding Thermal Shock: Furnace setters are often subject to rapid temperature changes, known as thermal shock, which can lead to cracking. Materials with higher thermal shock resistance, such as silicon carbide or cordierite, are less likely to crack under these conditions.

b. Maximum Use Temperature:

- Temperature Limits: Every ceramic material has a maximum use temperature, beyond which it starts to weaken and develop glassy phases that are prone to cracking. Selecting a material with an appropriate maximum use temperature for the intended application is crucial.

c. Thermal Conductivity and Expansion:

- Material Expansion: Differences in thermal expansion rates within the material can lead to internal stress and eventual cracking. Materials with balanced thermal conductivity and expansion rates are less likely to suffer from these stresses.

Enhanced Practical Solutions to Prevent Furnace Setter Cracking

To effectively combat the issue of cracking in furnace setters, it’s important to adopt a multi-faceted approach that encompasses material selection, design modifications, and process adjustments.

a. Material Selection:

- Optimized Material Choices: Selecting materials with optimal thermal shock resistance, such as silicon carbide or advanced refractory composites, can significantly reduce cracking risks. For high-temperature applications, high-alumina-content ceramics are recommended.

- Customized Material Composition: Adjusting the silica-to-alumina ratio in the ceramic composition can help in achieving a balance between thermal shock resistance and maximum use temperature, tailored to specific kiln conditions.

b. Design Modifications:

- Strategic Thermal Expansion Slots: Implementing thermal expansion slots in furnace setters can accommodate material expansion and contraction, thereby reducing thermal stress and minimizing cracking.

- Geometry Optimization: Redesigning the setters with rounded edges and corners or altering their shape can distribute thermal stresses more uniformly, further reducing the likelihood of cracking.

c. Process Adjustments:

- Controlled Heating and Cooling Rates: Gradual and uniform temperature changes in the kiln can significantly mitigate the risk of thermal shock. This approach is particularly beneficial for materials with lower thermal shock resistance.

- Even Heat Distribution: Ensuring uniform heat distribution within the kiln can prevent localized hotspots, which are often a precursor to cracking in furnace setters.

Conclusion: Balancing Material Properties with Design and Process

Preventing cracking in furnace setters is a matter of understanding the material properties, along with thoughtful design and process management. By selecting the right materials, incorporating design modifications, and adjusting the firing process, the longevity and effectiveness of ceramic kiln furniture can be significantly improved. This not only enhances the quality of ceramic products but also contributes to the efficiency and sustainability of ceramic production.

Contact Details

For further assistance and expert advice on selecting and maintaining ceramic kiln furniture, feel free to reach out.

Email: rongqi.chen@moatcity.com

WhatsApp: +447983626714

We are dedicated to supporting your ceramic production needs with our expertise.

Leave a Reply