Unveiling the Production Methods of Boron Nitride: From Powder to High-Performance Ceramics

Boron nitride (BN), widely regarded as one of the most versatile and high-performance ceramic materials, is used across diverse industries—from metallurgy and electronics to aerospace and nuclear engineering. Its exceptional properties, including high thermal conductivity, chemical inertness, and electrical insulation, are well documented. However, these functional attributes depend heavily on how boron nitride is synthesized and processed.

In this article, we explore the major production routes for boron nitride, the different physical forms it can take (powder, coatings, ceramics, and composites), and the challenges and innovations shaping its future.

-

Chemical Composition and Crystalline Forms

Before delving into manufacturing, it’s essential to understand the basic chemistry. Boron nitride consists of boron (B) and nitrogen (N) atoms in a 1:1 ratio, with several polymorphic structures:

Hexagonal BN (h-BN) – Graphite-like structure; most common form.

Cubic BN (c-BN) – Analogous to diamond; extremely hard.

Amorphous BN (a-BN) – Lacks long-range atomic order.

Wurtzite BN (w-BN) – Rare high-pressure phase.

The production method determines the resulting crystal structure, purity, and morphology, each of which impacts the final application.

-

Direct Synthesis from Elemental Precursors

One of the foundational approaches involves the direct chemical reaction between boron-containing and nitrogen-containing precursors.

-

Reaction of Boron Oxide with Ammonia or Nitrogen

This is one of the most widely used industrial methods:

B2O3(s)+2NH3(g)→2BN(s)+3H2O(g)B_2O_3 (s) + 2NH_3 (g) \rightarrow 2BN (s) + 3H_2O (g)B2O3(s)+2NH3(g)→2BN(s)+3H2O(g)

Carried out at temperatures of 900–1300°C.

Produces amorphous or poorly crystalline BN.

Followed by high-temperature annealing (>1500°C) to obtain hexagonal BN with higher crystallinity.

-

Reaction of Boric Acid with Urea or Melamine

A more economical and scalable route:

Boric acid (H₃BO₃) reacts with nitrogen-rich organics like urea or melamine.

Heated gradually to form a BN-carbon-nitrogen intermediate, which decomposes to BN at ~1000–1400°C.

This method is used to produce nano-sized BN powders, often used in polymer composites and coatings.

-

Carbothermic Nitridation

Another common approach involves:

B2O3(s)+C(s)+N2(g)→2BN(s)+CO(g)B_2O_3 (s) + C (s) + N_2 (g) \rightarrow 2BN (s) + CO (g)B2O3(s)+C(s)+N2(g)→2BN(s)+CO(g)

Conducted at temperatures >1500°C.

Uses carbon black or activated carbon as the reducing agent.

Offers better control over purity and particle morphology.

This method is more suitable for producing bulk BN powders with higher thermal stability and crystalline order.

-

Chemical Vapor Deposition (CVD)

CVD is used to produce thin films and coatings of boron nitride with precise control over thickness and purity.

- CVD Reaction Example

BCl3(g)+NH3(g)→BN(s)+3HCl(g)BCl_3 (g) + NH_3 (g) \rightarrow BN (s) + 3HCl (g)BCl3(g)+NH3(g)→BN(s)+3HCl(g)

Performed at temperatures between 900–1200°C.

Yields high-purity hexagonal BN films.

Can be deposited on semiconductors, metals, or ceramics.

CVD-grown BN is used in electronic devices, dielectric layers, and protective coatings, especially when a conformal or atomically thin layer is required.

-

High-Pressure, High-Temperature (HPHT) Synthesis of Cubic BN

Cubic boron nitride (c-BN)—the second hardest material after diamond—is synthesized under extreme conditions:

Pressure: 5–10 GPa

Temperature: 1500–2000°C

Requires catalysts such as alkali or transition metal nitrides.

This method is comparable to diamond synthesis and is used for:

Cutting tools

Abrasives

Wear-resistant components

Despite its excellent mechanical properties, the cost and complexity of HPHT synthesis limit c-BN’s widespread use.

-

Powder Processing and Shaping Techniques

BN, once synthesized as powder, must be formed into usable shapes or forms depending on the application.

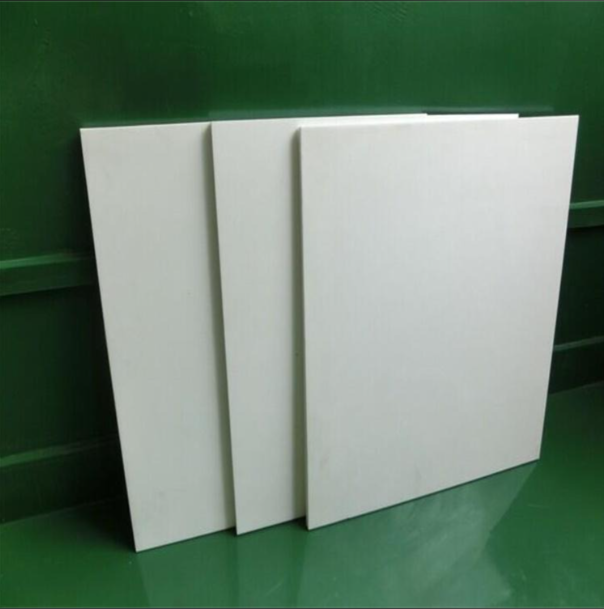

- Hot Pressing

BN powder is pressed under heat and pressure (~1800°C) to form dense ceramics.

Used to produce plates, crucibles, and insulators.

- Cold Isostatic Pressing (CIP) and Sintering

Offers better control over isotropy and density.

Followed by high-temperature sintering for grain bonding.

- Tape Casting and Extrusion

For thin sheets or hollow structures.

BN slurries are formed and cast, then dried and fired.

- Additive Manufacturing (3D Printing)

Emerging area using BN inks, pastes, or filaments.

Enables custom geometries and rapid prototyping of thermal insulators and dielectric parts.

-

Coating and Composite Fabrication

BN is often used as:

A filler in polymers or ceramics to enhance thermal conductivity and electrical insulation.

A coating on metals, molds, or tools to provide non-wettability, lubrication, and thermal protection.

Common techniques:

Spray coating

Electrophoretic deposition

Sol-gel processing

BN-based composites are used in thermal interface materials (TIMs), battery casings, and high-performance polymers.

-

Key Challenges and Future Directions

Despite its numerous benefits, BN manufacturing faces some challenges:

High synthesis temperatures and long processing times increase energy costs.

Scaling up HPHT processes for c-BN remains economically unviable for many sectors.

Controlling particle size and morphology is critical for consistent performance, especially in electronics.

Recent research is focusing on:

Low-temperature synthesis methods

Green chemistry routes (e.g., using renewable precursors)

Nanostructured BN (e.g., nanosheets, nanotubes) for next-gen electronics and thermal applications

Conclusion

Boron nitride’s exceptional performance in demanding environments is a direct result of its precise and carefully controlled synthesis methods. From traditional solid-state reactions to high-tech CVD and HPHT techniques, the choice of production route defines the form, structure, and application of the final product.

As material demands continue to rise—especially in electronics, aerospace, and energy storage—the ability to tailor BN at the micro and nano scale will be essential to unlocking its full potential.

Leave a Reply