Unveiling the Future: Advanced Innovations in Zirconia Dental Prosthetics Production

Introduction

The realm of dental prosthetics is undergoing a revolutionary transformation, spearheaded by the advancements in zirconia technology. Zirconia, renowned for its strength, durability, and aesthetic appeal, has become a cornerstone material in modern dentistry. This blog explores the cutting-edge innovations that are reshaping the production of zirconia dental prosthetics, paving the way for a new era in dental restoration and care.

Innovations in Material Science

1. Nanostructured Zirconia

Recent breakthroughs in material science have led to the development of nanostructured zirconia. This innovation involves engineering zirconia at the nanoscale, resulting in enhanced mechanical properties, such as increased fracture toughness and wear resistance. The fine-grain structure of nanostructured zirconia also contributes to a more natural and translucent appearance, closely mimicking the aesthetics of natural teeth.

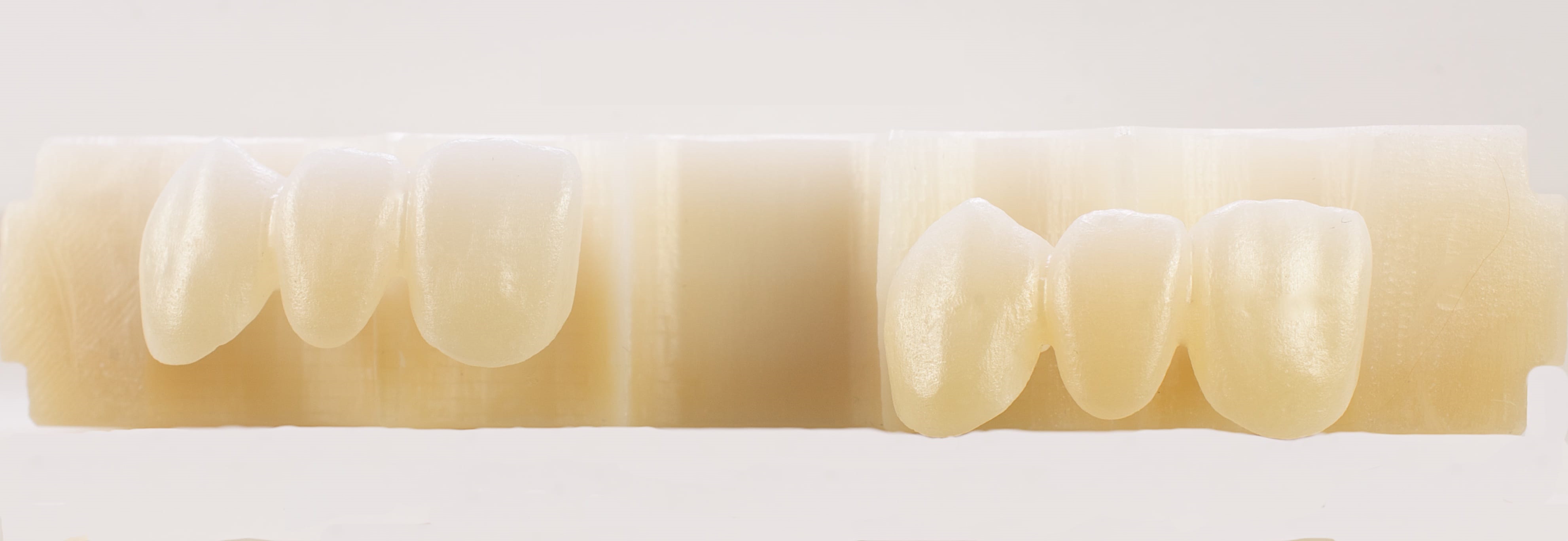

2. Multilayered Zirconia Discs

The introduction of multilayered zirconia discs marks a significant leap forward. These discs feature varying levels of translucency and strength throughout their structure, closely resembling the natural gradation of human teeth. This gradient effect not only improves the aesthetic outcome but also optimizes the material’s performance in different dental applications.

Technological Advancements in Manufacturing

1. Precision CAD/CAM Technology

Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) technologies have become more sophisticated, offering unprecedented precision in dental prosthetics manufacturing. Advanced software algorithms allow for intricate customization, ensuring that each zirconia prosthetic is tailored perfectly to the patient’s dental anatomy.

2. 3D Printing of Zirconia

3D printing technology has recently been adapted for the production of zirconia dental prosthetics. This method allows for layer-by-layer construction of the prosthetic, offering a high degree of design flexibility and rapid production capabilities. The potential for customization and the reduction in material waste make this a promising area for future development.

Enhancements in Sintering Processes

1. Low-Temperature Sintering

Innovations in sintering techniques, such as low-temperature sintering, have been developed to improve the overall quality of zirconia prosthetics. This process reduces the risk of zirconia degradation and preserves its translucency and color integrity, ensuring a more natural look.

2. Rapid Sintering Technology

Rapid sintering technology is another groundbreaking development. It significantly reduces the sintering time while maintaining the structural integrity of the zirconia. This efficiency boost not only speeds up the production process but also reduces energy consumption, contributing to a more sustainable manufacturing approach.

Conclusion

The advancements in the production of zirconia dental prosthetics represent a confluence of material science, technological innovation, and digital dentistry. These developments not only enhance the quality and performance of dental prosthetics but also promise a future where dental restorations are more accessible, efficient, and tailored to individual needs.

As we continue to witness these exciting innovations, the dental industry stands on the cusp of a new horizon, where the fusion of technology and dentistry will redefine what is possible in oral health and aesthetics.

For dental professionals and patients alike, staying informed about these advancements is key to making the most of the opportunities they present in the field of dental health and prosthetics.

Leave a Reply