The Unique Role of Boron Nitride in the Nuclear Industry

The nuclear industry is one of the most demanding sectors when it comes to materials performance. Components are expected to function under intense radiation, extreme temperatures, corrosive environments, and mechanical stress—often simultaneously. Among the advanced ceramics suited to meet these challenges, boron nitride (BN) stands out for its exceptional radiation resistance, neutron absorption capability, and chemical stability.

From neutron shielding and reactor control to high-temperature insulation and waste containment, BN plays a multifaceted role in both fission and fusion technologies. This article explores the unique properties of boron nitride that make it indispensable in the nuclear field and examines current and emerging applications.

-

Nuclear-Relevant Properties of Boron Nitride

Boron nitride comes in various polymorphs, but hexagonal boron nitride (h-BN) is the most commonly used form in nuclear applications. Its physical and chemical characteristics provide multiple advantages:

| Property | Nuclear Industry Relevance |

| High thermal stability | Stable up to 2000 °C in inert atmospheres |

| Excellent neutron absorption | Due to high ¹⁰B isotope content |

| Low neutron activation | Produces minimal radioactive waste post-irradiation |

| Chemical inertness | Resists corrosion from coolants and fission products |

| Radiation resistance | Maintains structure under neutron and gamma flux |

| Electrical insulation | Supports high-voltage isolation in reactor systems |

| Low density | Reduces structural load in core assemblies |

-

Neutron Absorption: The Boron Advantage

The standout feature of BN in nuclear applications is its content of the ¹⁰B (boron-10) isotope, which has a high neutron absorption cross-section (~3840 barns for thermal neutrons). This makes BN a natural choice for:

Neutron shielding and moderation

Control rods and burnable poison inserts

Neutron detectors and dosimeters

Unlike pure boron, which is brittle and reactive, BN offers the advantage of mechanical formability and chemical stability in solid ceramic form, making it easier to machine and integrate into reactor assemblies.

Comparison of Common Neutron Absorbers:

| Material | Neutron Absorption | Mechanical Stability | Corrosion Resistance |

| Boron carbide (B₄C) | Very high | Brittle | Moderate |

| Cadmium | High | Soft metal | Toxic, limited use |

| Boron nitride | High (with ¹⁰B) | Good (as h-BN/c-BN) | Excellent |

In many designs, BN is used alongside B₄C or embedded within matrix composites to provide mechanical reinforcement.

-

Radiation Stability and Structural Integrity

Materials in nuclear environments must maintain dimensional and mechanical stability under high neutron and gamma flux. BN demonstrates:

Low neutron-induced swelling

Minimal phase transformation under irradiation

Resistance to radiation-induced embrittlement

These features make it ideal for:

Reactor internal insulators

Fusion reactor structural components

Instrumentation housings in irradiation test loops

Even under prolonged exposure, BN retains thermal conductivity and dielectric strength, outperforming many polymer-based or oxide insulators.

-

Chemical Compatibility with Coolants and Fuel

In advanced nuclear systems—particularly fast reactors, molten salt reactors (MSRs), and fusion reactors—materials must resist attack from corrosive coolants such as:

Liquid sodium (Na)

Molten lead-bismuth eutectic (LBE)

Molten fluorides and chlorides

Boron nitride is chemically inert to many of these media, especially in its hot-pressed or sintered forms. It can be used in:

Core liners and insulators in MSRs

Sensor sheaths and thermowell casings

Fuel element claddings (under development)

Its non-reactivity with actinides and fission products also makes BN a promising candidate for nuclear waste immobilization or containment matrices.

-

Role in Fusion Energy

In fusion reactors such as tokamaks and stellarators, plasma-facing materials must endure:

Extremely high heat flux (up to 20 MW/m²)

Neutron fluxes from D-T fusion reactions

Plasma-induced erosion

BN is being explored for:

Edge plasma insulators

Diagnostic housing components

Ceramic coatings on metallic substrates

Its low Z (atomic number) minimizes plasma contamination, and it maintains structural integrity in vacuum environments, which are essential for steady-state fusion operation.

-

Boron Nitride Composites and Advanced Forms

To overcome certain limitations—such as poor oxidation resistance in air above 900 °C—researchers are developing BN-based composites, such as:

BN–SiC (silicon carbide) ceramics for enhanced toughness and oxidation resistance

BN nanocomposites with reinforced mechanical strength

Coated BN particles for improved environmental durability

These materials are paving the way for multifunctional reactor components that can act as thermal, electrical, and radiation barriers simultaneously.

-

Manufacturing and Safety Considerations

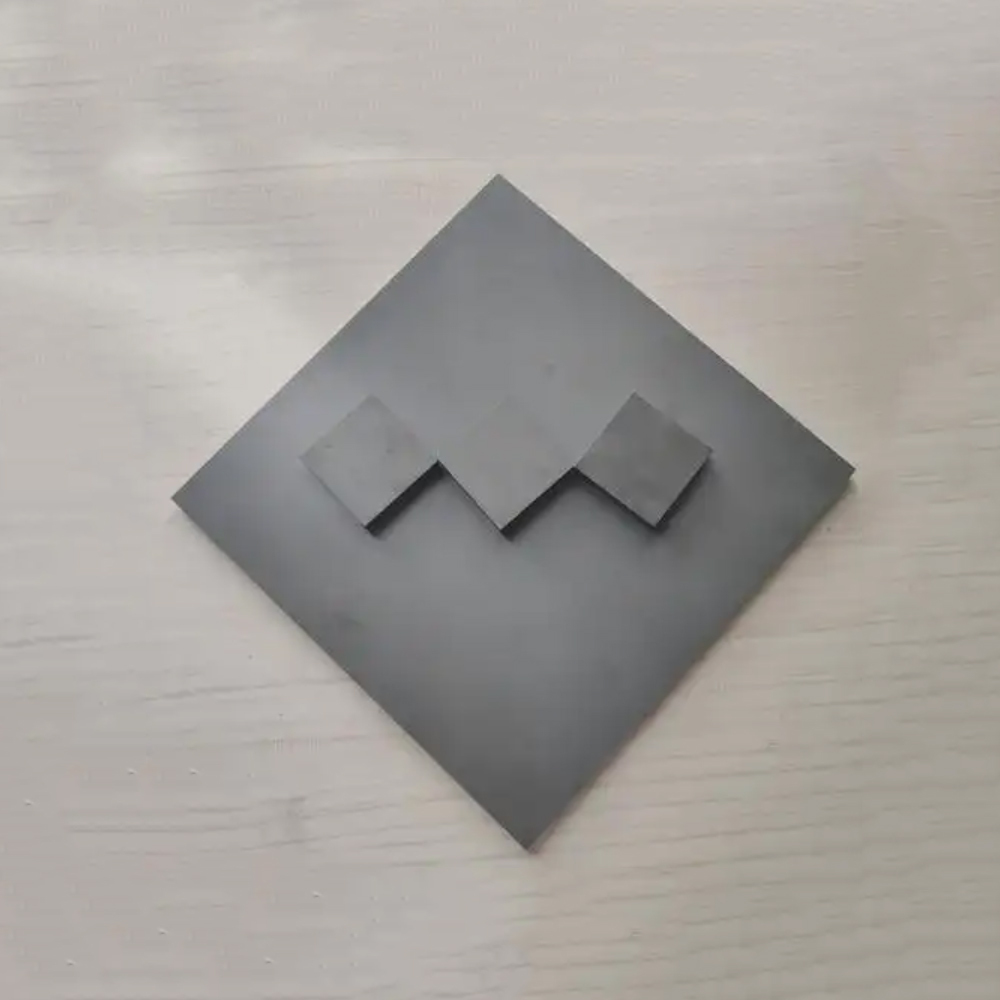

BN can be hot-pressed, machined, or 3D printed into complex geometries with tight tolerances.

Its low activation and low toxicity make it safer to handle and dispose of compared to alternatives like cadmium or hafnium.

As ¹⁰B is a critical isotope, enriched BN materials are carefully controlled and used where neutron capture is essential.

Conclusion: A Quiet Workhorse in Nuclear Engineering

Boron nitride may not be as well-known as B₄C or zirconium alloys in nuclear applications, but its unique blend of thermal, chemical, dielectric, and neutron-absorbing properties gives it an increasingly important role.

From shielding neutron flux to protecting sensitive instrumentation and enabling advanced reactor designs, BN is a silent workhorse in the push for cleaner, safer, and more efficient nuclear energy. As new reactor technologies evolve and fusion energy inches closer to reality, BN will likely play an expanding role in fueling the future of nuclear power.

Leave a Reply