The Rising Popularity of Corundum-Mullite Saggers/Trays in Zirconia Teeth Manufacturing

Introduction

In the realm of dental prosthetics manufacturing, particularly with zirconia teeth, the choice of materials used at every stage of production is pivotal. Among these, corundum-mullite saggers or trays have been gaining increasing popularity. This blog post delves into the reasons behind this trend and explores how corundum-mullite has emerged as a preferred material in the manufacturing of zirconia teeth, offering insights into its significant impact on the quality and efficiency of dental prosthetics production.

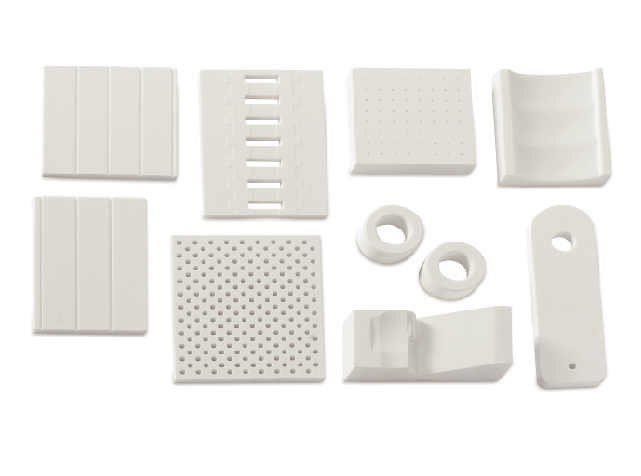

Understanding Corundum-Mullite Saggers/Trays

Corundum-mullite, a composite ceramic material, brings together the strength and thermal resistance of alumina (corundum) with the thermal shock resistance and durability of silica (mullite). This synthesis results in a material ideally suited for the rigorous conditions of zirconia sintering, providing a robust solution for dental prosthetics manufacturing processes.

Reasons Behind Their Growing Popularity

- Exceptional Thermal Stability: Corundum-mullite’s capability to withstand the extreme temperatures required in the sintering process of zirconia teeth, reaching up to 1,700°C, without deformation, ensures consistent performance crucial for manufacturing high-quality dental prosthetics.

- Superior Resistance to Thermal Shock: Its durability under rapid temperature changes prevents cracking and damage, enhancing the longevity of the saggers/trays and translating to cost savings over time due to reduced replacements.

- High Mechanical Strength: The inherent strength of corundum-mullite aids in maintaining the precise shape and size of zirconia teeth during high-temperature sintering, a critical factor for achieving the exact dimensions and fit required for dental prosthetics.

- Chemical Inertness and Purity: By not reacting with zirconia or other materials in the furnace, corundum-mullite minimizes the risk of contamination that could otherwise affect the aesthetics and integrity of the final dental products.

- Enhanced Aesthetic and Functional Quality: The saggers/trays allow for uniform heat distribution, essential for producing zirconia teeth with consistent color, density, and mechanical properties, thereby enhancing both aesthetic and functional quality.

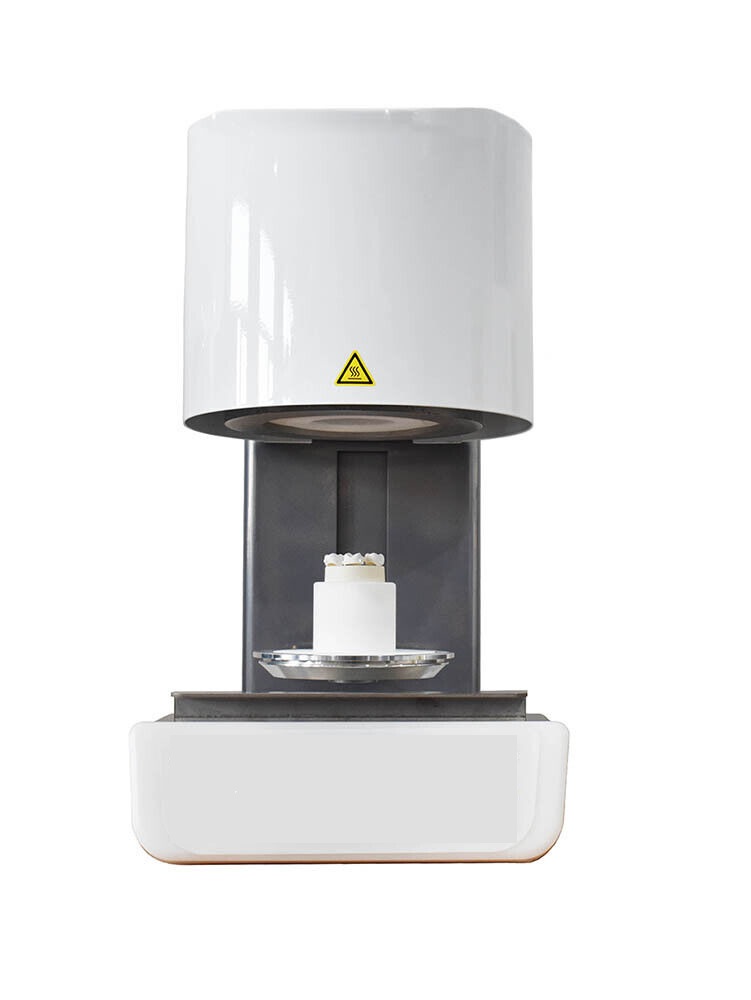

The Impact on the Manufacturing Process

The utilization of corundum-mullite saggers/trays brings about increased efficiency and improved quality control in the manufacturing of zirconia dental prosthetics. Their durability and exceptional performance contribute to maintaining high standards of quality in dental prosthetic production.

Environmental and Economic Considerations

The sustainability and economic benefits of corundum-mullite saggers/trays are notable. Their longevity and reduced maintenance needs contribute to a more sustainable manufacturing process by minimizing waste and the frequency of replacements. While the initial investment in these saggers/trays might be higher, the long-term savings they enable due to their durability and reduced upkeep make them an economically advantageous choice.

FAQs

- How does the use of corundum-mullite saggers/trays affect the overall cost of zirconia teeth manufacturing?

- While the initial cost might be higher, their durability and efficiency lead to cost savings in the long run.

- Are corundum-mullite saggers/trays suitable for all types of dental ceramic sintering?

- Their properties make them suitable for a wide range of ceramic sintering processes, including those for different dental ceramics.

- Can the use of corundum-mullite saggers/trays speed up the manufacturing process?

- Their ability to provide consistent heat distribution can lead to more efficient sintering cycles, potentially speeding up the process.

- Is specialized handling required for corundum-mullite saggers/trays?

- Basic training for handling these materials is recommended, especially to understand their thermal properties and maintenance.

Contact Us

For more information on our products and services, please contact Moat City:

Email: rongqi.chen@moatcity.com

Web: www.moatcity.com/contact

WhatsApp: +447983626714

Leave a Reply