The Backbone of Modern Kilns: R-SiC in Kiln Furniture Applications

In the heart of every modern industrial kiln, an unsung hero works tirelessly under extreme conditions – the kiln furniture. These are the beams, posts, setters, and saggers that support products during the firing process. Among the various materials used for these critical components, Recrystallized Silicon Carbide (R-SiC) has emerged as the premium choice for the most demanding applications. Its unique combination of properties has revolutionized thermal processing across multiple industries, enabling higher quality, greater efficiency, and unprecedented productivity.

The evolution of kiln furniture mirrors the advancement of industrial processing itself. Traditional materials like fireclay and cordierite served adequately for slower firing cycles and lower temperatures. However, as manufacturing demands increased – with higher firing temperatures, faster cycle times, and stricter quality requirements – these materials reached their limitations. The introduction of silicon carbide-based materials marked a significant step forward, with R-SiC representing the pinnacle of this development.

The superiority of R-SiC for kiln furniture stems from its exceptional high-temperature mechanical properties. Unlike metallic supports that soften and creep, or oxide ceramics that weaken significantly at elevated temperatures, R-SiC actually increases in strength up to approximately 1600°C. This remarkable characteristic allows kiln furniture made from R-SiC to support heavier loads at higher temperatures without sagging or deforming. The significance of this cannot be overstated – it enables tighter stacking configurations, larger batch sizes, and ultimately greater throughput per firing cycle.

Perhaps the most valued property of R-SiC in kiln applications is its outstanding thermal shock resistance. Modern manufacturing demands rapid thermal cycling to maximize productivity and minimize energy consumption. Where traditional materials would crack under the stress of rapid temperature changes, R-SiC components withstand these conditions effortlessly. This capability allows manufacturers to implement aggressive heating and cooling rates that would be impossible with other materials, significantly reducing cycle times while maintaining product quality.

The high thermal conductivity of R-SiC provides another crucial advantage. It ensures uniform temperature distribution throughout the kiln load, eliminating hot spots that can cause product variation and reducing thermal gradients that lead to stress in the furniture itself. This thermal uniformity is particularly critical in technical ceramics and electronic component manufacturing, where consistent thermal treatment is essential for product performance and reliability.

The practical benefits of R-SiC kiln furniture translate directly to economic advantages. While the initial investment is higher than alternative materials, the total cost of ownership is often lower. R-SiC’s durability means longer service life – typically years instead of months – reducing replacement costs and production downtime for maintenance. The ability to withstand faster firing cycles increases production capacity without additional capital investment in kiln space. The improved temperature uniformity reduces scrap rates and improves product quality, providing further economic benefits.

Different industries leverage these advantages in various ways. In the sanitaryware industry, R-SiC beams support heavy ceramic pieces through rapid firing cycles that would destroy conventional furniture. The tile industry utilizes R-SiC plates and setters for fast single-fired processes, where thermal shock resistance is paramount. In technical ceramics and electronics, the purity of R-SiC prevents contamination of sensitive components during firing, while providing the precise temperature control required for these advanced materials.

The design of R-SiC kiln furniture has evolved to maximize these benefits. Modern components feature optimized geometries that minimize thermal mass while maintaining structural integrity. Advanced manufacturing techniques allow for complex shapes with precise dimensional control, ensuring perfect fit and alignment in kiln car setups. The development of specialized coatings has further enhanced performance, providing additional protection against specific atmospheric conditions or reducing sticking with certain materials.

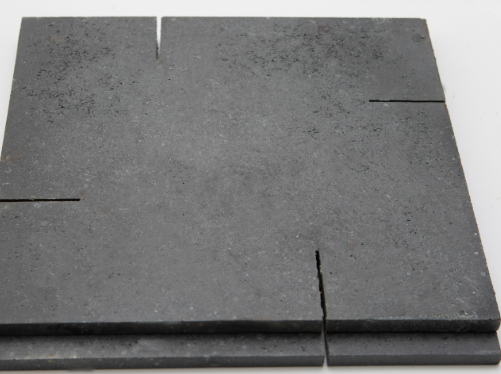

However, the use of R-SiC kiln furniture requires proper handling and maintenance. While incredibly durable under operating conditions, the material’s brittleness makes it susceptible to damage from impact or improper handling. Regular inspection for cracks or damage is essential, as compromised components can affect kiln performance and product quality. Proper loading techniques and alignment are crucial to avoid point loading and ensure even stress distribution.

The transition to R-SiC kiln furniture often requires some process adjustment. The different thermal properties may necessitate modifications to firing curves to fully leverage the material’s capabilities. Kiln atmosphere considerations become more important, particularly in reducing conditions where the protective silica layer may not form effectively. However, these adjustments are typically straightforward and the benefits quickly outweigh the implementation efforts.

As industrial thermal processing continues to evolve toward higher efficiency and greater precision, R-SiC kiln furniture remains at the forefront of this progression. Its unique properties enable manufacturing capabilities that would otherwise be impossible, supporting innovation across multiple industries while providing economic and environmental benefits through reduced energy consumption and waste.

Leave a Reply