The Advantages of Corundum-Mullite Saggers/Trays in Zirconia Teeth Manufacturing

1. Introduction to the Advantages of Corundum-Mullite Saggers/Trays in Zirconia Teeth Manufacturing:

In the precise world of zirconia teeth manufacturing, selecting the right materials for every tool and component is crucial. Among these, the choice of saggers or trays stands out for its significant impact on the final product’s quality. This blog post explores the unique advantages of using corundum-mullite saggers/trays in the highly specialized field of zirconia dental prosthetics manufacturing.

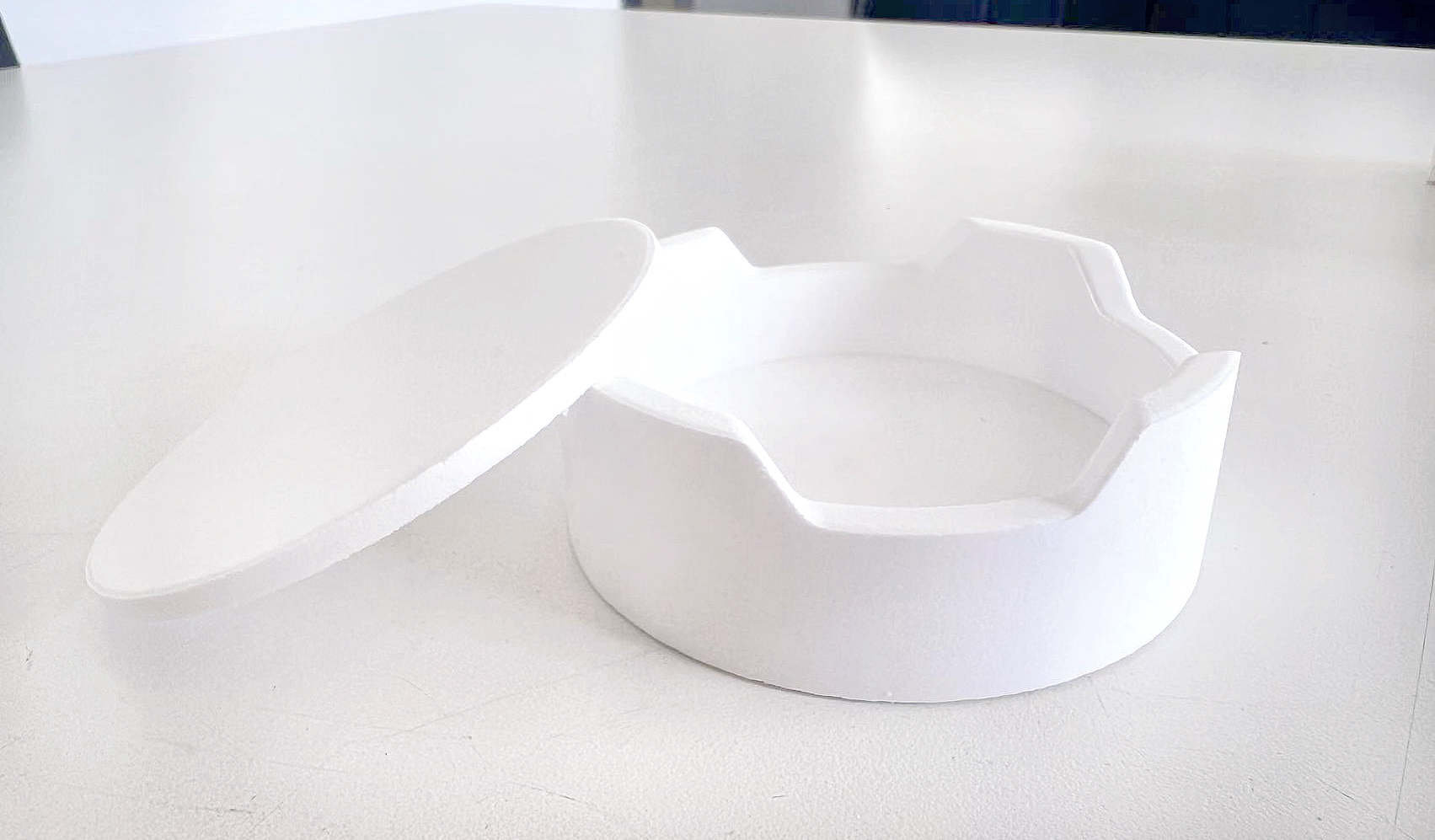

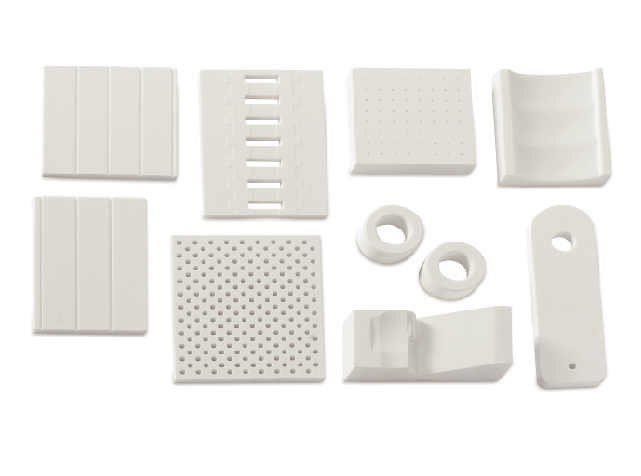

2. Understanding Corundum-Mullite Saggers/Trays:

Corundum-mullite is a composite ceramic material made primarily of alumina (corundum) and silica (mullite), known for its exceptional thermal stability, mechanical strength, and resistance to thermal shock. These properties make it an ideal choice for zirconia teeth manufacturing processes.

a. High Thermal Stability:

- Enduring High Temperatures: Corundum-mullite saggers/trays withstand the high sintering temperatures required in zirconia teeth manufacturing without deforming, ensuring consistent performance and results.

b. Resistance to Thermal Shock:

- Durability and Longevity: The ability to withstand rapid temperature changes without cracking extends the lifespan of saggers/trays, making them a cost-effective option.

c. Mechanical Strength:

- Support and Protection: Their high mechanical strength supports the weight of zirconia teeth during sintering without warping or breaking, crucial for maintaining precise shape and dimensions.

d. Reduced Contamination Risk:

- Chemical Inertness: Corundum-mullite’s chemical inertness minimizes the risk of contamination, crucial for maintaining the quality of zirconia teeth.

e. Enhanced Aesthetic Quality:

- Uniform Heating and Cooling: The thermal properties of corundum-mullite contribute to uniform heating and cooling, ensuring consistent color and texture in zirconia teeth.

3. Impact on the Manufacturing Process:

The use of corundum-mullite saggers/trays enhances manufacturing efficiency and aids in maintaining high standards of quality control in the production of zirconia dental prosthetics. Their durability and reliability contribute significantly to efficiency and quality control in the manufacturing process.

4. The Future of Corundum-Mullite in Zirconia Manufacturing:

With ongoing advancements in ceramic materials technology, the potential applications and efficiencies of corundum-mullite saggers/trays in zirconia teeth manufacturing continue to expand, promising even greater improvements in quality and efficiency.

5. FAQs:

- Cost Implications: While initially more expensive, the durability and longevity of corundum-mullite saggers/trays can lead to cost savings over time.

- Maintenance Requirements: They require minimal maintenance, with regular inspections recommended to check for cracks or wear.

- Versatility: Suitable for a variety of high-temperature ceramic sintering applications beyond zirconia dental prosthetics.

- Investment Justification for Small-Scale Manufacturers: The long-term benefits in quality and efficiency justify the initial investment for manufacturers of all sizes.

6. Conclusion:

Corundum-mullite saggers/trays offer significant advantages in the manufacturing of zirconia teeth, contributing to enhanced quality, efficiency, and productivity. Their unique properties and potential for future advancements make them an invaluable asset in the field of dental prosthetics manufacturing.

7. Contact Details:

For more insights into our corundum-mullite saggers and trays and their impact on zirconia dental prosthetics manufacturing, reach out to Moat City.

Email: rongqi.chen@moatcity.com

Web: www.moatcity.com

WhatsApp: +447983626714

Explore how Moat City’s advanced solutions can elevate the quality of your zirconia dental prosthetics.

Leave a Reply