Sustainable Solutions: Evaluating the Environmental and Economic Benefits of Ceramic Setters in Metal Injection Molding (MIM) Processes

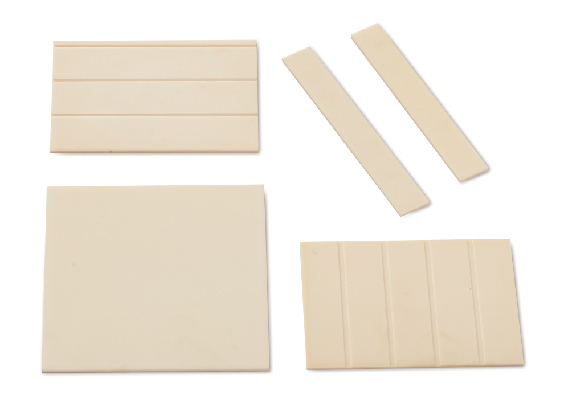

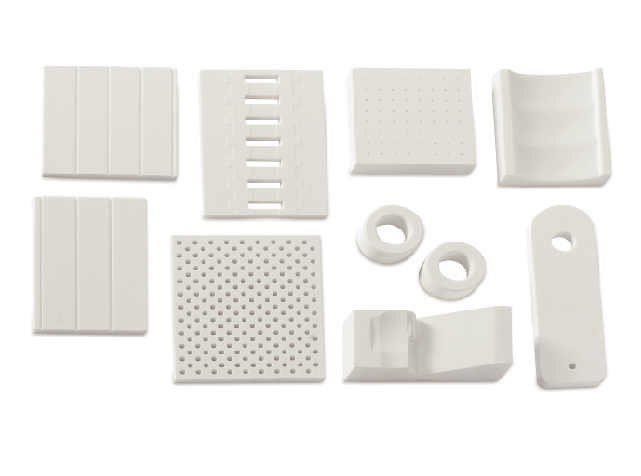

In the ever-evolving landscape of manufacturing, sustainability and cost-effectiveness have emerged as key pillars guiding industry practices. Metal Injection Molding (MIM) stands as a prime example of a sustainable and efficient manufacturing process, offering a viable alternative for producing complex metal components. Central to the success of MIM operations are ceramic setters, which play a crucial role in supporting green parts during debinding and sintering stages. In this blog, we delve into the profound benefits of ceramic setters on sustainability and cost-effectiveness in MIM processes.

Resource Efficiency: Ceramic setters contribute to resource efficiency by enabling the production of intricate metal components with minimal material waste. Unlike traditional machining methods that generate significant scrap material, MIM utilizes a powder metallurgy approach, where metal powders are mixed with binders to form feedstock. Ceramic setters facilitate the consolidation and shaping of green parts, optimizing material utilization and reducing waste generation. This resource-efficient approach aligns with sustainable manufacturing principles, minimizing environmental footprint and conserving valuable resources.

Energy Savings: The thermal processing stages of MIM, including debinding and sintering, require substantial energy inputs. Ceramic setters play a vital role in optimizing energy efficiency by providing thermal insulation and heat retention properties. By minimizing heat loss and promoting uniform heating, ceramic setters help reduce energy consumption during MIM operations. This translates to lower utility costs and reduced greenhouse gas emissions, contributing to overall sustainability efforts within the manufacturing sector.

Extended Lifecycle: High-quality ceramic setters are engineered to withstand harsh operating conditions and repeated thermal cycling, resulting in extended service life compared to disposable alternatives. This durability not only reduces the frequency of setter replacement but also minimizes waste generation associated with disposable fixtures. By investing in long-lasting ceramic setters, manufacturers can achieve significant cost savings over time, while simultaneously reducing their environmental impact through reduced waste generation.

Process Optimization: Ceramic setters enable precise control over debinding and sintering processes, allowing for optimization of process parameters such as temperature profiles, atmosphere composition, and dwell times. By fine-tuning these parameters, manufacturers can achieve higher throughput, improved part quality, and reduced scrap rates. This optimization leads to increased production efficiency and cost-effectiveness, as well as enhanced sustainability through the reduction of material and energy waste.

Recyclability and Reusability: Ceramic setters are inherently recyclable and reusable, further enhancing their sustainability credentials. At the end of their service life, ceramic setters can be recycled or repurposed for other applications, minimizing landfill waste and conserving raw materials. Additionally, setters that are no longer suitable for use in MIM processes can often be refurbished or reground to extend their lifecycle, providing a cost-effective and environmentally friendly solution for manufacturers.

Conclusion:

Ceramic setters play a pivotal role in driving sustainability and cost-effectiveness in Metal Injection Molding (MIM) processes. By optimizing resource efficiency, reducing energy consumption, extending lifecycle, enabling process optimization, and promoting recyclability and reusability, ceramic setters offer a holistic approach to sustainable manufacturing. As the manufacturing industry continues to prioritize environmental stewardship and cost efficiency, the adoption of ceramic setters in MIM processes represents a tangible step towards achieving these goals. Embracing sustainable solutions not only benefits the bottom line but also ensures a greener and more resilient future for generations to come.

Leave a Reply