Safety Hazards and Prevention Strategies in Lithium Battery Assembly Processes

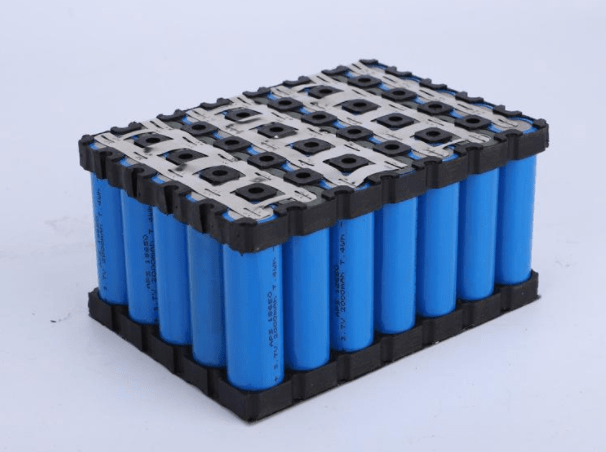

The assembly of lithium-ion batteries is a critical stage that significantly impacts the overall safety and performance of the final product. This process involves integrating various components such as electrodes, separators, and electrolytes into a cohesive and functional battery. However, several safety hazards may arise during this stage, including short circuits, electrolyte leakage, and thermal runaway. This blog will explore these common safety issues in depth and provide specific prevention strategies and operational guidelines to ensure a safe and efficient assembly process.

Common Safety Hazards in Lithium-Ion Battery Assembly

1. Short Circuits

Short circuits are one of the most serious dangers in the battery assembly process. When the positive and negative electrodes come into direct contact due to improper alignment, separator damage, or contamination, a short circuit can occur. This can lead to overheating, fires, or even explosions.

2. Electrolyte Leakage

Improper sealing of the battery casing, damage during assembly, or material defects can cause electrolyte leakage. Electrolyte leakage can lead to chemical burns, environmental contamination, and reduced battery performance.

3. Thermal Runaway

Thermal runaway is a dangerous situation where a temperature increase causes further temperature rise, resulting in a self-sustaining and uncontrollable reaction. This can be triggered by internal short circuits, overcharging, or physical damage during assembly.

4. Mechanical Damage

During assembly, battery components may suffer mechanical damage, such as punctured or compressed electrodes or casings. This can compromise the structural integrity of the battery, leading to short circuits, leakage, or performance degradation.

5. Contamination

Contamination from dust, moisture, or foreign particles during assembly can negatively affect the electrochemical properties of the battery. This could lead to internal short circuits, capacity loss, or safety issues during the battery’s lifecycle.

Prevention Strategies and Operational Guidelines

1. Strict Quality Control

Implementing strict quality control measures throughout the assembly process is essential. This includes regular inspection of raw materials, components, and intermediate products to ensure they meet the required standards. Automated optical inspection systems can detect alignment issues, contamination, and defects in real time.

2. Controlled Environment

Maintaining a clean and controlled assembly environment significantly reduces the risk of contamination. Cleanrooms equipped with HEPA filters and controlled humidity and temperature help prevent dust and moisture from damaging battery components.

3. Precision Assembly Equipment

Using high-precision assembly equipment minimizes the risk of mechanical damage and component misalignment. Robotic assembly systems equipped with advanced sensors and vision systems ensure the accurate placement and handling of delicate battery parts.

4. Robust Sealing Technologies

Adopting strong sealing technologies and materials can prevent electrolyte leakage. Methods such as ultrasonic welding, laser welding, and other advanced sealing techniques offer reliable, secure seals. Additionally, regular leak tests using methods like helium leak detection can ensure the integrity of the battery casing.

5. Comprehensive Training and Safety Protocols

Providing comprehensive training to assembly line workers is crucial to ensure they understand potential hazards and adhere to appropriate safety protocols. Regular safety drills, emergency response training, and clear operational guidelines help foster a safety culture within the assembly facility.

6. Temperature and Pressure Monitoring

Continuous monitoring of temperature and pressure during assembly helps detect and mitigate early signs of thermal runaway. Installing sensors and automatic shutdown mechanisms can prevent dangerous situations from escalating.

Conclusion

The assembly of lithium-ion batteries presents multiple safety challenges that must be carefully managed to ensure the production of safe and reliable batteries. By implementing strict quality control, maintaining controlled environments, using precision equipment, adopting robust sealing technologies, providing comprehensive training, and monitoring critical parameters, manufacturers can effectively reduce these risks. These strategies not only enhance the safety of the assembly process but also improve the overall performance and lifespan of lithium-ion batteries, supporting their widespread application in various high-demand sectors.

![Anti-erosion and ultra-long life Superb Saggars For Lithium & Sodium Batteries [ML-CD-CM-50]](https://moatcity.com/wp-content/uploads/2024/10/1728623992313.png)

Leave a Reply