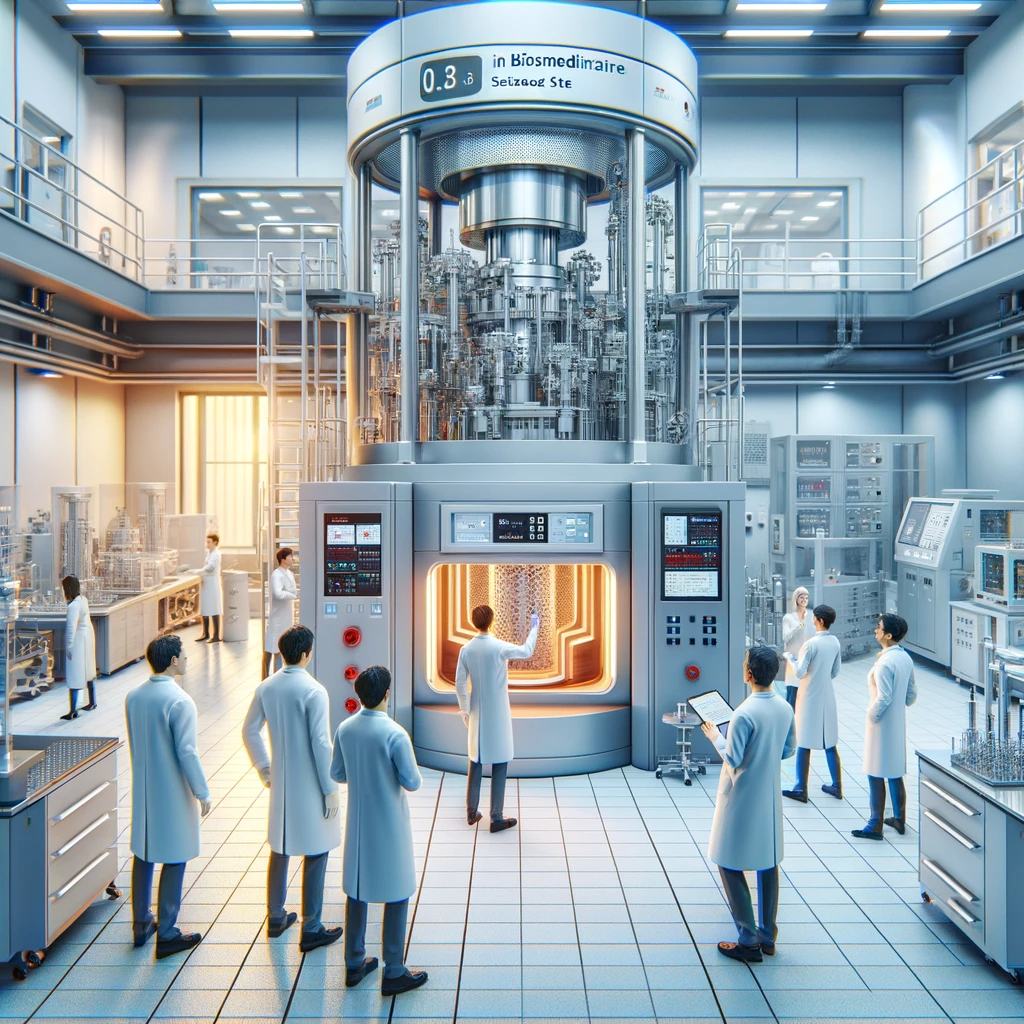

Revolutionizing Biomedical Sintering with High-Quality Ceramic Furnace Setters

In the intricate world of biomedical manufacturing, precision and quality are paramount. From dental implants to orthopedic implants, the components used in biomedical applications demand exceptional durability, biocompatibility, and precision in their production. Sintering, a crucial step in the manufacturing process, requires the use of advanced materials and technologies to achieve the desired outcomes.

One such technological marvel is the utilization of ceramic furnace setters crafted from high-quality materials like corundum mullite, 99% pure alumina, and zirconia. These setters play a pivotal role in the sintering process, offering unparalleled benefits and applications in the biomedical industry.

Understanding Sintering in Biomedical Manufacturing

Sintering is a process that involves the compacting and heating of powdered materials to form solid objects without melting them completely. In biomedical manufacturing, sintering is utilized to produce a wide array of components such as dental crowns, implants, and orthopedic devices. The sintering process not only enhances the mechanical properties of these components but also ensures biocompatibility and longevity.

The Role of Ceramic Furnace Setters

Ceramic furnace setters act as a foundational element in the sintering process, providing crucial support and thermal stability to the components being processed. The choice of materials for furnace setters is of utmost importance, especially in biomedical applications where purity, stability, and resistance to thermal shock are non-negotiable.

Corundum Mullite: Corundum mullite, renowned for its exceptional thermal shock resistance and high-temperature stability, is a favored material for furnace setters in biomedical sintering. Its ability to withstand extreme temperatures without deformation or degradation ensures uniform heat distribution and consistent sintering results.

99% Pure Alumina: 99% pure alumina setters offer unparalleled purity and inertness, making them ideal for sintering biomedical components. Alumina setters provide excellent resistance to chemical corrosion and ensure minimal contamination during the sintering process, preserving the integrity and biocompatibility of the final products.

Zirconia: Zirconia setters combine high strength, thermal insulation, and chemical inertness, making them indispensable in biomedical sintering applications. Zirconia setters provide stable support to delicate components during sintering, preventing warping or distortion while maintaining precise dimensional accuracy.

Applications in Biomedical Sintering

The applications of ceramic furnace setters in biomedical sintering are diverse and far-reaching:

Dental Implants and Crowns: Ceramic furnace setters facilitate the sintering of dental implants and crowns with exceptional precision and biocompatibility. The use of high-quality setters ensures the uniform consolidation of ceramic powders, resulting in durable and aesthetically pleasing dental restorations.

Orthopedic Implants: Biomedical sintering relies on ceramic setters to produce orthopedic implants with precise dimensions and mechanical properties. Corundum mullite and alumina setters enable the sintering of bioinert materials such as titanium and hydroxyapatite, creating implants that integrate seamlessly with the human body.

Surgical Instruments: Ceramic furnace setters play a crucial role in the manufacturing of surgical instruments used in orthopedic and dental procedures. Their thermal stability and inertness ensure the reliable sintering of instrument components, guaranteeing optimal performance and longevity in clinical settings.

Conclusion

In the realm of biomedical manufacturing, the sintering process stands as a cornerstone for producing components that meet the highest standards of quality and performance. Ceramic furnace setters, crafted from materials like corundum mullite, 99% pure alumina, and zirconia, represent a pinnacle of engineering excellence in biomedical sintering applications. Their exceptional thermal stability, purity, and resistance to thermal shock make them indispensable tools for shaping the future of biomedical implants and devices, ushering in an era of innovation and excellence in healthcare.

Leave a Reply