Optimizing Sintering Temperatures for Advanced Ceramic Materials: A Focus on Silicon Carbide

Understanding the Importance of Sintering Temperature in Ceramic Manufacturing

In the manufacturing of advanced ceramics, sintering is a critical step that dictates the final material properties such as strength, hardness, wear resistance, and thermal stability. The process of determining the ideal sintering temperature is complex and highly dependent on the material’s composition, particle size, and the presence of any sintering aids. Among high-performance ceramics, silicon carbide (SiC) presents particular challenges due to its high melting point and unique thermal and mechanical properties. This article delves into how to optimize sintering temperatures, particularly for SiC, to achieve optimal material performance and quality.

Key Principles of Sintering Temperature Determination

Sintering temperature is primarily determined based on several factors, including the material’s melting point, the type of sintering aids used, the particle size distribution, and the desired final properties of the ceramic. The goal is to heat the powder material to a temperature where particle diffusion and bonding occur effectively, while avoiding excessive melting or incomplete sintering.

Sintering Temperature and Melting Point Relationship

- The sintering temperature is typically set between 60% and 80% of the material’s melting point. This ensures that diffusion between particles occurs efficiently without the material becoming too molten.

- For silicon carbide, which has an exceptionally high melting point of around 2700°C, sintering typically occurs between 1600°C and 2200°C, depending on the application.

The Role of Particle Size

- The size of the ceramic powder particles directly affects the sintering process. Smaller particles have a larger surface area, facilitating quicker diffusion and bonding, which allows for sintering at relatively lower temperatures.

- Larger particles require higher temperatures to achieve effective sintering and densification, as they have fewer contact points for diffusion.

Use of Sintering Aids

- In the case of silicon carbide, sintering aids (such as aluminum oxide or yttria) are often used to promote densification at lower temperatures. These aids help to lower the overall sintering temperature by enhancing the bond formation between particles.

- The choice and quantity of sintering aids used will directly affect the optimal sintering temperature, making it essential to carefully select and control their use.

Solving the Sintering Temperature Challenge

Experimental Optimization

- The most common method for determining the optimal sintering temperature is through experimental trials. Manufacturers can conduct sintering tests at different temperatures, evaluating the final material properties such as hardness, density, and porosity to identify the best temperature range.

- For instance, conducting sintering trials at various temperatures and analyzing results such as mechanical strength and density will provide insights into the ideal temperature for specific applications.

Material Composition Considerations

- The chemical composition of a ceramic material greatly impacts its sintering behavior. For SiC, the presence of impurities or sintering aids can affect the temperature requirements.

- Understanding the material’s composition and its interaction with sintering aids is essential for optimizing the sintering temperature.

Atmosphere Control

- Sintering atmosphere also plays a significant role in temperature selection. Silicon carbide, for example, is often sintered in an inert atmosphere (such as nitrogen or argon) or in vacuum conditions to prevent oxidation and maintain the desired material properties.

- By controlling the sintering atmosphere, manufacturers can optimize the sintering temperature and improve the overall quality of the final product.

Simulation and Computational Models

- Modern computational techniques, such as finite element analysis (FEA), allow manufacturers to simulate the sintering process. These simulations can predict how different sintering temperatures will affect material properties, helping to optimize the sintering process without the need for extensive trial-and-error.

- By using simulations to model the temperature distribution and particle behavior, manufacturers can determine the ideal sintering parameters in advance.

Sintering Silicon Carbide: Applications and Temperature Considerations

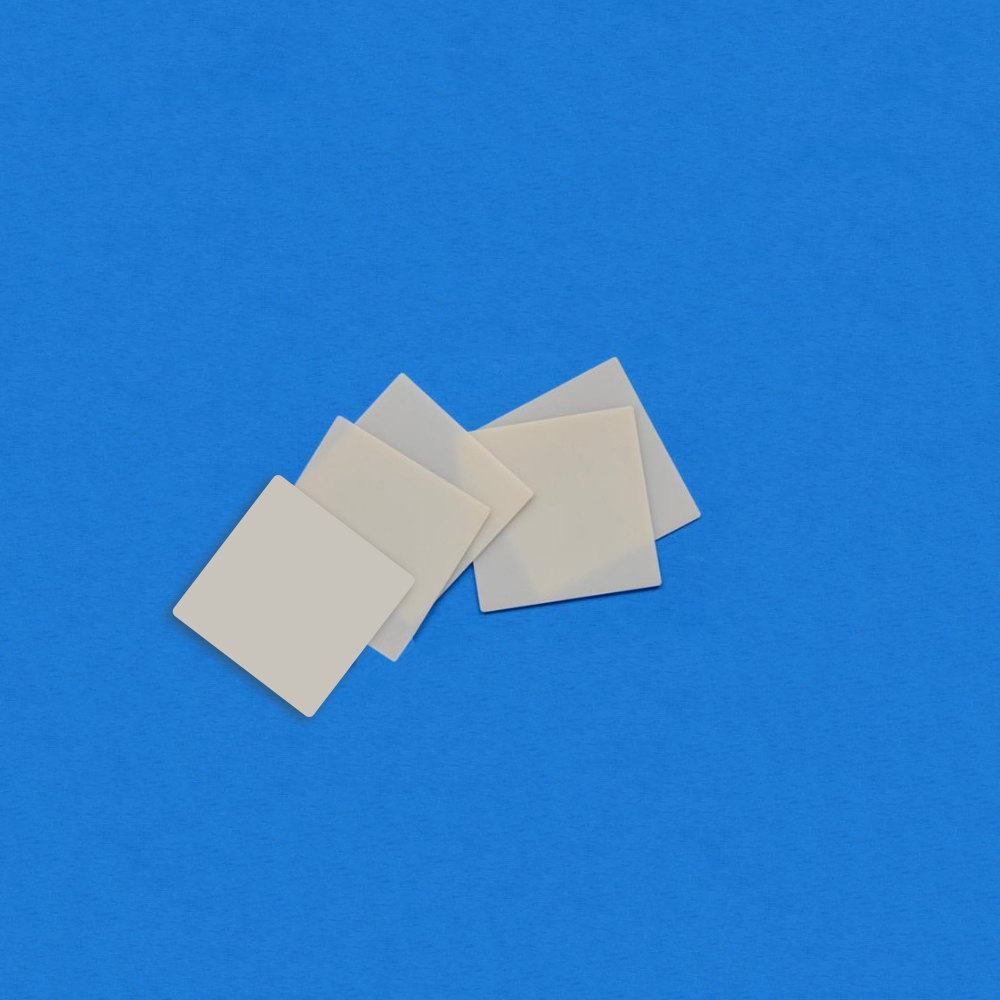

Silicon carbide is a material known for its exceptional thermal stability, wear resistance, and mechanical strength. These properties make SiC an ideal candidate for applications in harsh environments such as aerospace, electronics, and advanced mechanical components. The sintering temperature for SiC must be carefully controlled to maintain these desirable properties while avoiding degradation during the process.

High-Temperature Applications

- For high-temperature applications, such as the manufacturing of furnace linings, heat exchangers, or aerospace components, SiC requires a higher sintering temperature to achieve the necessary strength and density. Sintering temperatures in the range of 2100°C to 2200°C are typical for these applications.

Wear-Resistant and Corrosion-Resistant Components

- For components that require high wear resistance, such as seals, bearings, and cutting tools, sintering temperatures must be carefully adjusted to achieve the right balance of hardness and toughness. Excessively high sintering temperatures may cause the material to become too brittle, while low temperatures may result in insufficient densification.

Electronic and Semiconductor Applications

- In the semiconductor industry, silicon carbide is used for its high thermal conductivity and high breakdown voltage. Sintering temperatures for electronic-grade SiC are typically lower, between 1600°C and 1800°C, to ensure the material maintains its electronic properties without excessive thermal degradation.

Conclusion

The process of determining the optimal sintering temperature is a crucial factor in the manufacturing of advanced ceramics, particularly for materials like silicon carbide. By carefully considering factors such as material composition, particle size, sintering aids, and atmospheric conditions, manufacturers can effectively control the sintering temperature to produce high-performance ceramic materials.

Through a combination of experimental testing, careful composition analysis, and advanced simulation techniques, sintering temperatures can be optimized to achieve the best material properties for specific applications. In the case of silicon carbide, precise control over sintering temperatures not only enhances its mechanical and thermal properties but also ensures its reliability in demanding applications such as aerospace, electronics, and heavy-duty machinery.

Leave a Reply