New Insight for Ceramics/Refractory: 'Mastering Sintering' Guide Released!

1. Introduction to Advanced Sintering Techniques:

In the intricate realm of ceramics and refractory manufacturing, mastering the art of sintering is crucial. The ‘Mastering Sintering’ guide, a valuable resource previously sold at $299, is now available for free. This blog post explores essential insights from the guide to enhance your manufacturing processes.

2. Summary of the ‘Mastering Sintering’ Guide:

Delve into the depths of sintering mastery with our guide’s 12 proven strategies. Each of these strategies is crafted to streamline your ceramics manufacturing process, ensuring both cost-efficiency and high-quality outcomes.

[Strategy 1] – 5 Untold Secrets of Furnace Efficiency: Maximizing Output Minimizing Costs

- Explore innovative materials for high-efficiency furnace linings, such as silicon carbide and advanced alumina composites, to enhance thermal stability and reduce operational costs.

- Optimize furnace atmosphere control, including the use of inert gases or vacuum conditions, to maintain product purity and quality.

- Implement energy recovery systems, like regenerative burners, to capture and reuse waste heat, significantly reducing energy consumption.

- Utilize advanced thermal insulation techniques with materials like microporous insulators and aerogels to drastically reduce heat loss.

- Integrate AI and automation for precision control in furnace operations, optimizing temperature, heating rates, and cooling cycles.

[Strategy 2] – 3 Steps to Identifying Hidden Losses in Kiln/Furnace Insulation

- Employ thermal imaging technology to detect heat leaks and pinpoint insulation weaknesses or failures.

- Evaluate and possibly upgrade insulation materials to more advanced options like ceramic fibre or microporous insulators for enhanced efficiency.

- Regularly monitor performance and compare against industry benchmarks to identify insulation inefficiencies and optimize operational efficiency.

[Strategy 3] – Advanced Strategies for Sintering Efficiency: Data-Driven Insights

- Emphasize precision in temperature control to reduce energy consumption and enhance quality and cost-efficiency.

- Ensure uniform heat distribution to lower defect rates and increase the yield of high-quality products.

- Use advanced materials to extend the life of kiln furniture, reducing replacement frequency and downtime.

- Customize sintering cycles for specific products to improve energy efficiency and maximize quality.

- Implement efficient insulation techniques and real-time process monitoring to reduce energy loss and process variability.

[Strategy 4] – The Cost-Quality Equation: Breaking the Myth in Refractory Manufacturing

- Challenge the traditional belief that higher quality in refractory materials always means higher costs. Embrace new trends and methods that allow for both good quality and reasonable costs.

- Utilize technological advancements and process optimization to improve efficiency and reduce costs without compromising product quality.

- Achieve economies of scale to benefit from bulk purchasing of raw materials and more efficient use of manufacturing resources.

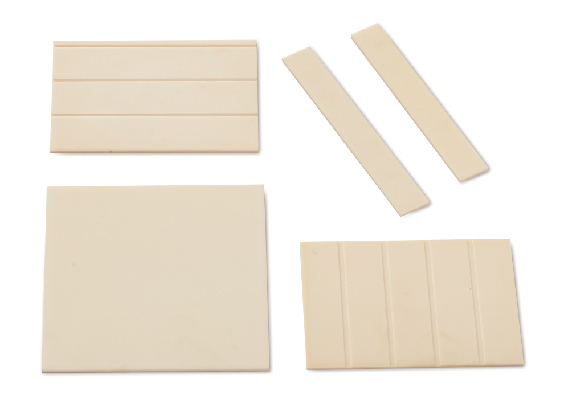

[Strategy 5] – Behind the Scenes: Furnace Setters and Kiln Furniture in Production

- Understand the dual role of kiln furniture and furnace setters in enhancing production, including efficient space utilization and ensuring uniform heat distribution.

- Focus on material innovation and design optimization for kiln furniture and furnace setters to minimize defects and enhance energy and cost efficiency.

[Strategy 6] – Durability and Economy: The Long-Term Advantages of Superior Saggers

- Recognize the critical role of saggers in sintering processes like battery materials and zirconia powder, balancing initial investment against long-term benefits in both durability and cost-efficiency.

- Consider material compatibility and conduct a cost-benefit analysis of durability to ensure operational efficiency and quality control.

[Strategy 7] – Tailored for Success: Custom Solutions and Their Impact on Savings

- Embrace the trend towards customization in kiln furniture and furnace setters, responding to varied demands of the industry with an extensive collection of custom molds.

- Reap the benefits of customization, including increased sintering volume/capacity, improved heat distribution, and enhanced airflow management.

[Strategy 8] – The Global Playbook: Navigating International Markets and Trade Terms

- Gain insights into navigating international trade by understanding various trade terms and their implications for a smooth transaction.

- Consider channels and strategies for sourcing from China, including direct from factories, through trading companies, and online platforms.

- Implement effective risk management tips, such as hiring a local agent, diversifying supply sources, and ensuring comprehensive contracts.

[Strategy 9] – Unlocking Long-Term Success: The Power of Partnering with Suppliers Committed to Sustainability

- Understand the importance of choosing suppliers committed to sustainability for compliance and risk mitigation, resource efficiency, and cost-effectiveness.

- Recognize the benefits of sustainable practices, including energy efficiency, waste reduction, and long-term strategic thinking.

- Appreciate the value of social responsibility and ethical practices in supplier relationships.

[Strategy 10] – Crack No More: The Ultimate Guide to Understanding Kiln Furniture Durability

- Address common failure modes in kiln furniture, focusing on thermal shock resistance, mechanical stress management, chemical corrosion resistance, and more.

- Implement design adaptations in different furnace types and materials to enhance kiln furniture durability and performance.

[Strategy 11] – Informed Decisions: A Comprehensive Checklist for Potential Buyers

- Utilize a structured approach to evaluate potential suppliers and products, focusing on pivotal aspects for successful procurement.

- Streamline the evaluation process to mitigate risks and establish beneficial partnerships with suppliers.

[Strategy 12] – The Road Ahead: Trends And Innovations in Ceramics & Refractories

- Explore emerging trends in the ceramics and refractories industries, including increased adoption in residential and commercial sectors, and the rise of electronic ceramics.

- Embrace clean energy solutions through the use of ceramics in photovoltaic modules and e-glass, and understand the growing demand for advanced ceramics.

- Discover technological advancements in kiln furniture and the increasing focus on customization for optimized performance and efficiency.

3. The Transformative Impact of These Strategies:

Detailed case studies and real-world examples demonstrate the transformative impact of these sintering strategies on manufacturing efficiency and product quality. Learn how businesses have achieved a 38% reduction in costs and a 99% success rate in their operations.

4. Get Your Free Copy of the Guide:

For a limited time, the comprehensive ‘Mastering Sintering’ guide, valued at $299, is available for free. This is a golden opportunity for professionals in the ceramics and refractory field to gain access to expert knowledge and strategies that have been proven successful in over 1400 cases. Download your free copy today at www.moatcity.com/downloads to check how these strategies can be applied to your business.

5. Conclusion:

‘Mastering Sintering’ is more than just a guide; it’s a gateway to elevating your ceramics and refractory manufacturing processes. Harness the power of these expert strategies to transform your production efficiency and product quality.

6. Contact Details:

For further insights and expert consultations, reach out to us at Moat City.

Email: rongqi.chen@moatcity.com

Web: www.moatcity.com

WhatsApp: +447983626714

Leave a Reply