Navigating the Journey: Tackling Challenges in Maintaining and Optimizing Ceramic Furnace Setters for Metal Injection Molding (MIM)

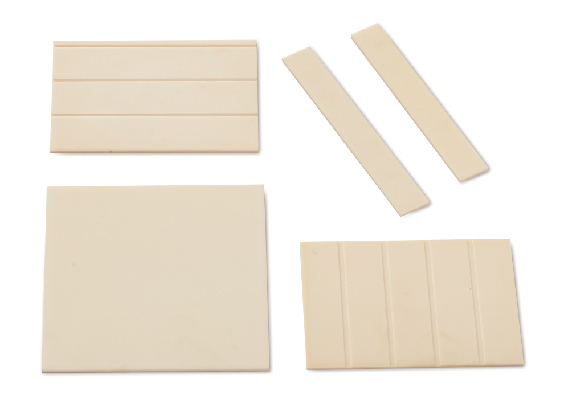

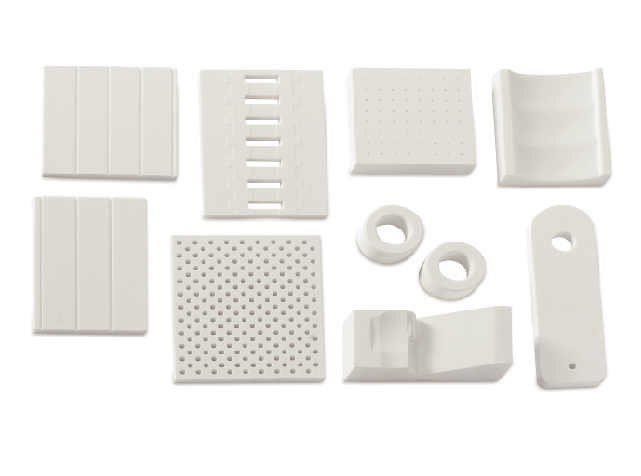

Metal Injection Molding (MIM) stands as a beacon of innovation in the manufacturing landscape, offering a cost-effective solution for producing intricate metal components. At the heart of MIM processes lie ceramic furnace setters, providing essential support during debinding and sintering stages. While these setters are instrumental in ensuring the success of MIM operations, they also present unique challenges in terms of maintenance and optimization. In this blog, we’ll explore these challenges and discuss strategies for overcoming them to maximize the efficiency and effectiveness of ceramic furnace setters in MIM.

Thermal Degradation: The harsh thermal environments encountered during debinding and sintering can lead to degradation of ceramic furnace setters over time. Thermal cycling, exposure to high temperatures, and chemical interactions with binders can all contribute to wear and tear. To overcome this challenge, regular inspection and maintenance protocols are essential. Implementing preventive maintenance schedules, such as routine cleaning and inspection for signs of damage, can help identify issues early and prolong the lifespan of furnace setters.

Dimensional Stability: Maintaining dimensional stability is crucial for ensuring the integrity of metal components produced via MIM. However, ceramic furnace setter may experience dimensional changes due to thermal expansion and contraction during heating and cooling cycles. To address this challenge, selecting high-quality ceramic materials with minimal thermal expansion coefficients is imperative. Additionally, optimizing process parameters, such as heating rates and dwell times, can help minimize dimensional variations and ensure consistent part quality.

Contamination Control: Contamination from residual binders and lubricants can compromise the purity of metal components and affect the performance of ceramic furnace setters. Controlling contamination requires a multi-faceted approach, including proper handling and storage of green parts, thorough cleaning of furnace setters between batches, and optimizing debinding parameters to minimize residue formation. Investing in advanced cleaning technologies, such as ultrasonic cleaning systems, can enhance the effectiveness of contamination control measures.

Wear and Erosion: The abrasive nature of metal powders used in MIM processes can cause wear and erosion of ceramic furnace setters over time. This wear can lead to surface roughness, dimensional inaccuracies, and reduced lifespan of setters. To mitigate wear and erosion, manufacturers can explore alternative ceramic formulations with enhanced wear resistance, such as silicon carbide or alumina-zirconia composites. Additionally, implementing proper handling techniques and utilizing protective coatings can help extend the service life of furnace setters.

Optimization of Process Parameters: Achieving optimal performance of ceramic furnace setters requires fine-tuning process parameters to suit specific MIM applications. Factors such as heating rates, sintering temperatures, atmosphere composition, and dwell times can significantly impact the performance and efficiency of setters. Employing advanced process monitoring and control systems, such as thermocouples and programmable logic controllers (PLCs), enables real-time adjustment of parameters to optimize furnace performance and ensure consistent part quality.

Conclusion:

While ceramic furnace setters play a critical role in Metal Injection Molding (MIM) processes, they also pose unique challenges in terms of maintenance and optimization. By implementing proactive maintenance strategies, controlling contamination, addressing wear and erosion, and optimizing process parameters, manufacturers can overcome these challenges and maximize the efficiency and effectiveness of ceramic furnace setters in MIM operations. Embracing innovation and leveraging advanced technologies are key to navigating the journey of maintaining and optimizing ceramic furnace setters, ultimately ensuring the success of MIM endeavors and driving excellence in metal component manufacturing.

Leave a Reply