Mastering Precision: The Role of Ceramic Furnace Setters in Technical Ceramics Manufacturing

In the intricate world of technical ceramics, where precision and reliability are paramount, ceramic furnace setters emerge as unsung heroes, orchestrating the delicate balance of heat, time, and atmosphere essential for crafting high-performance ceramic components. In this blog, we delve into the pivotal role of ceramic furnace setters in the manufacturing process of technical ceramics and explore how their expertise ensures the quality and integrity of these advanced materials.

Understanding Technical Ceramics

Technical ceramics, also known as engineering ceramics or advanced ceramics, encompass a diverse array of ceramic materials engineered to possess exceptional mechanical, thermal, electrical, and chemical properties. These ceramics find applications in a wide range of industries, including aerospace, automotive, electronics, healthcare, and energy, where traditional materials often fall short.

The Crucial Role of Ceramic Furnace Setters

Ceramic furnace setters play a central role in the manufacturing process of technical ceramics, overseeing the firing and sintering stages that transform raw ceramic powders into high-performance components. Their expertise and attention to detail ensure that each ceramic piece emerges from the kiln with the desired properties and performance characteristics.

Precision Temperature Control

One of the primary responsibilities of ceramic furnace setters is to maintain precise temperature profiles throughout the firing process. Technical ceramics often require specific temperature ranges and heating rates to achieve optimal densification and crystalline structure. Ceramic furnace setters carefully monitor temperature gradients, adjusting furnace settings as needed to ensure uniform heating and prevent thermal stress on the ceramic materials.

Atmosphere Management

The atmosphere within the kiln during firing plays a crucial role in the sintering of technical ceramics. Ceramic furnace setters regulate the composition of gases within the kiln to create the ideal environment for sintering. By controlling factors such as oxygen levels and gas flow rates, they prevent unwanted chemical reactions and ensure the purity and integrity of the ceramic materials.

Kiln Loading and Unloading

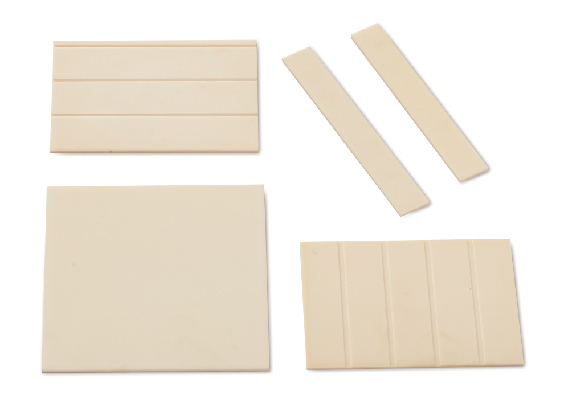

Loading and unloading the kiln require precision and care to avoid damage to fragile ceramic components. Ceramic furnace setters meticulously arrange the ceramic pieces within the kiln, optimizing spacing and ventilation for even heat distribution. They oversee the loading and unloading process, minimizing breakage and maximizing kiln capacity to optimize production efficiency.

Quality Assurance and Inspection

Throughout the firing process, ceramic furnace setters conduct rigorous quality assurance checks to evaluate the progress of the ceramics and identify any defects or irregularities. They inspect the color, texture, and dimensions of the ceramic components, ensuring that only the highest-quality materials meet stringent industry standards.

Driving Innovation and Excellence

In addition to their operational roles, ceramic furnace setters play a pivotal role in driving innovation and process optimization in technical ceramics manufacturing. Their insights and expertise contribute to the development of novel firing techniques, advanced kiln designs, and sustainable manufacturing practices, pushing the boundaries of what is possible in ceramic engineering.

Conclusion: Honoring the Craftsmanship of Ceramic Furnace Setters

In the dynamic world of technical ceramics, ceramic furnace setters stand as guardians of precision and quality, ensuring that each ceramic component meets the exacting standards of performance and reliability. Their mastery of temperature control, atmosphere management, and quality assurance is instrumental in shaping the future of ceramic engineering, driving innovation and excellence across diverse industries. As we celebrate the remarkable properties and applications of technical ceramics, let us also recognize and appreciate the indispensable contributions of ceramic furnace setters, whose expertise and dedication propel the advancement of ceramic technology forward.

Leave a Reply