Key Technologies in Sintering Saggers/Trays for Zirconia Teeth Manufacturing

1. Introduction to Precision Engineering in Sintering Saggers/Trays for Zirconia Dental Prosthetics:

The manufacturing of zirconia dental prosthetics hinges on the sophistication of the sintering process, where the precision and technology of sintering saggers/trays play a critical role. This article delves into the engineering advancements behind sintering saggers/trays, elucidating their impact on the fidelity and characteristics of zirconia dental prosthetics.

2. Advanced Materials and Design of Sintering Saggers/Trays:

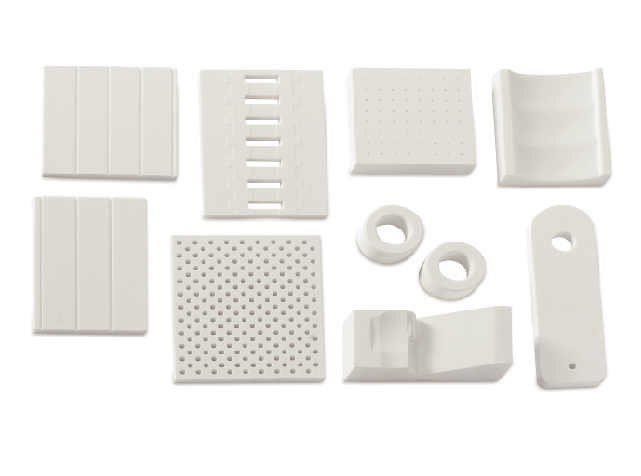

The architecture and composition of sintering saggers/trays are foundational to their performance in the extreme environments of zirconia sintering. Utilizing materials like advanced alumina, zirconia composites, and silicon carbide, these containers are engineered to withstand temperatures upwards of 1500°C while ensuring minimal thermal expansion and remarkable durability against thermal shock.

3. Innovations in Sintering Saggers/Trays Technology:

a. Material Innovation:

- High-Performance Ceramics: The integration of ultra-high purity alumina and zirconia-based ceramics enhances thermal stability and resistance to wear, essential for the repeated sintering cycles of dental prosthetics.

- Composite Materials: The development of composite ceramics, incorporating elements like silicon nitride, offers unprecedented thermal shock resistance and strength, optimizing the lifespan and reliability of saggers/trays.

b. Precision Design and Engineering:

- Computer-Aided Design (CAD): Leveraging CAD for intricate design allows for saggers/trays that accommodate specific geometries and sizes of zirconia blanks, ensuring uniform heat treatment and dimensional accuracy.

- Finite Element Analysis (FEA): FEA simulations predict the thermal and mechanical behavior of saggers/trays under sintering conditions, guiding design optimizations for enhanced performance.

c. Enhanced Thermal Efficiency:

- Uniform Heat Distribution: Innovations in design and material composition enable uniform heat distribution, critical for achieving homogeneous sintering and mechanical properties across the zirconia prosthetics.

- Advanced Temperature Control: The incorporation of temperature control mechanisms, such as thermocouples and infrared sensors, within saggers/trays setups, allows for precise monitoring and adjustment of sintering profiles.

d. State-of-the-Art Manufacturing Techniques:

- Precision Manufacturing: Advanced manufacturing techniques, including isostatic pressing and CNC machining, yield saggers/trays with exceptional dimensional tolerance and surface finish.

- Automated Quality Assurance: Employing automated optical inspection and laser scanning ensures each sagger/tray meets stringent quality criteria, pivotal for reproducible sintering outcomes.

4. Impact of Technological Advancements on Zirconia Teeth Quality:

- Dimensional Stability: The technical innovations in saggers/trays guarantee the dimensional stability of zirconia teeth post-sintering, directly influencing fit and function.

- Enhanced Aesthetic Outcome: Consistency in sintering conditions afforded by these advancements leads to superior color and translucency uniformity, meeting the aesthetic expectations of dental prosthetics.

5. Emphasizing Sustainability and Efficiency:

- Optimized Energy Use: The efficiency gains from improved thermal management result in lower energy consumption and reduced operational costs, underpinning the sustainability efforts in dental manufacturing.

- Extended Service Life: The durability and thermal resilience of advanced saggers/trays materials contribute to their longevity, decreasing the frequency of replacement and the associated environmental impact.

6. The Future Landscape of Sagger/Tray Technology:

Continual advancements in material science and precision engineering forecast the evolution of sagger/tray technology, aiming for even higher efficiency, quality, and sustainability in zirconia teeth manufacturing.

7. FAQs:

- Operational Lifespan: Modern materials and engineering practices have significantly extended the operational lifespan of saggers/trays, contributing to cost-effectiveness.

- Effect on Sintering Time: Enhanced thermal efficiency and control can substantially optimize sintering times, improving throughput without compromising quality.

- Cost-Benefit Analysis: Despite higher initial costs, the long-term operational savings, and quality improvements present a compelling case for investment in advanced sagger/tray technologies.

- Training Requirements: While some training is necessary, it primarily focuses on maximizing the benefits of these technologies through proper handling and operational practices.

8. Conclusion:

The relentless pursuit of excellence in sintering technology underscores the commitment to advancing zirconia dental prosthetics manufacturing. The strategic integration of advanced materials, precision engineering, and thermal management showcases a future where dental prosthetics are synonymous with unmatched quality and efficiency.

9. Contact Details:

For further insights into the technological advancements in our sintering saggers and trays and their role in enhancing zirconia dental prosthetics manufacturing, contact Moat City.

Email: rongqi.chen@moatcity.com

Web: www.moatcity.com

WhatsApp: +447983626714

Discover how Moat City’s cutting-edge solutions are transforming the quality of your zirconia dental prosthetics.

Leave a Reply