Key Sintering Factors to Consider for Getting High Thermal Conductivity in Aluminum Nitride (AlN) Ceramics

1. Introduction:

Aluminum Nitride (AlN) ceramics are renowned for their unique thermal and electrical properties, making them indispensable in various industrial applications such as integrated circuits, semiconductors, and microwave devices. This article delves into the crucial sintering factors that affect the thermal conductivity of AlN ceramics.

2. The Importance of Thermal Conductivity:

Thermal conductivity is a measure of a material’s ability to conduct heat. In AlN ceramics, high thermal conductivity is essential for optimal performance in high-temperature and high-frequency applications.

3. Challenges in Achieving High Thermal Conductivity:

a. Covalent Nature of AlN:

- Low Atomic Diffusion: The covalent nature of AlN results in low atomic self-diffusion coefficients, making it challenging to achieve high sintering densities.

- Sublimation: Pure AlN powder tends to sublimate at temperatures between 2260-2500°C, complicating the sintering process.

b. Powder Granularity:

- Surface Energy: Finer powder particles have higher surface energy, providing a greater driving force for the sintering process.

- Material Transfer: Smaller particle sizes facilitate material transfer during sintering, aiding in achieving higher densities.

c. Additives:

- Type and Amount: The type and amount of sintering additives can significantly influence the sintering process and the resulting thermal conductivity.

4. Key Sintering Factors:

a. Powder Fineness:

- Particle Size: Finer particles provide a greater surface area, thereby increasing the driving force for sintering.

- Uniform Distribution: A uniform particle size distribution is crucial for achieving homogeneous sintering.

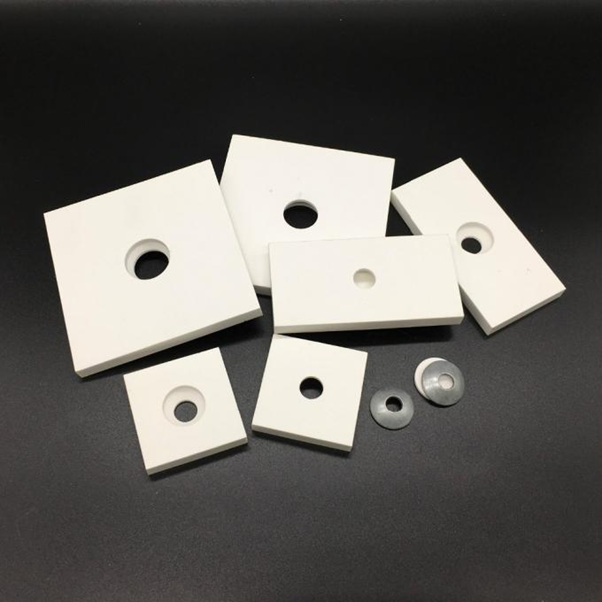

5. Shaping Process:

The pressure applied during the shaping process not only affects the green body’s strength but also influences the contact density of the raw powder, which can impact the sintering process.

a. Dry Pressing:

- Pressure Impact: Higher forming pressure leads to more compact contact between powder particles, facilitating material transfer and aiding in sintering.

- Mould Wear: Excessive pressure can lead to mould wear and uneven density distribution, causing layer separation or fractures during demolding.

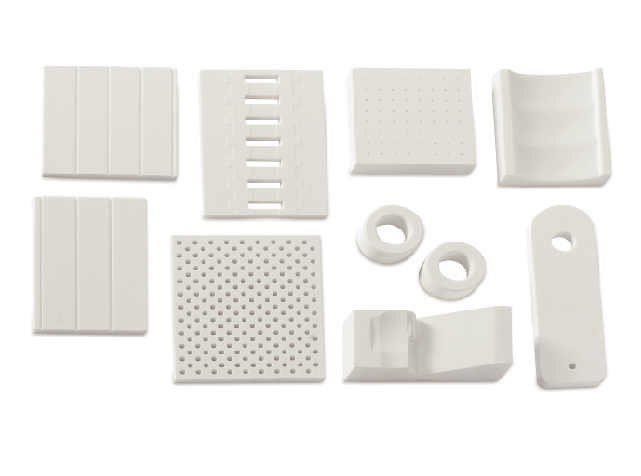

b. Slip Casting and Injection Molding:

- Binders: These methods involve the use of various binders, which, if not completely removed during the debinding process, can lead to sintering defects like bubbling or cracking.

6. Sintering Additives:

a. Common Additives:

- Y2O3: Yttrium oxide is the most commonly used sintering additive. It reacts with the Al2O3 on the surface of AlN particles, forming a liquid phase that aids in rearrangement and densification.

- Other Oxides and Fluorides: Other additives like CaO, Sm2O3, and La2O3 can also be used to facilitate the sintering process.

b. Optimal Additive Amount:

- Balance: The amount of sintering additive must be optimized to avoid excessive secondary phase formation, which can impede thermal conductivity.

7. Conclusion:

Achieving high thermal conductivity in AlN ceramics requires a deep understanding of the sintering process. By considering factors like powder granularity, shaping process, and sintering additives, one can significantly improve the thermal conductivity of AlN ceramics.

8. Contact Details:

For more information on high thermal conductivity AlN ceramics and how Moat City can assist you, please contact us.

Email: rongqi.chen@moatcity.com

Web: www.moatcity.com

WhatsApp: +447983626714

We’re eager to assist with your high thermal conductivity AlN ceramics needs.

Leave a Reply