Innovative Solutions: Ceramic Furnace Setters Redefining Powder Metallurgy Processes

Powder metallurgy, a manufacturing process that converts powdered metals into dense, solid metal parts, has long been lauded for its efficiency, precision, and ability to produce parts with unique properties. Central to its success is the sintering process, where powdered metal is heated below its melting point until the particles fuse together. The quality of the final product heavily relies on the uniformity of heat distribution and the control of atmospheric conditions during this phase. This is where ceramic furnace setters, often overlooked, come into play, offering innovative solutions that are redefining powder metallurgy processes.

The Critical Role of Ceramic Furnace Setters

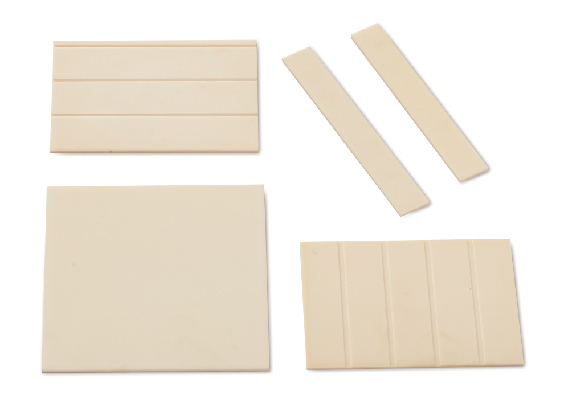

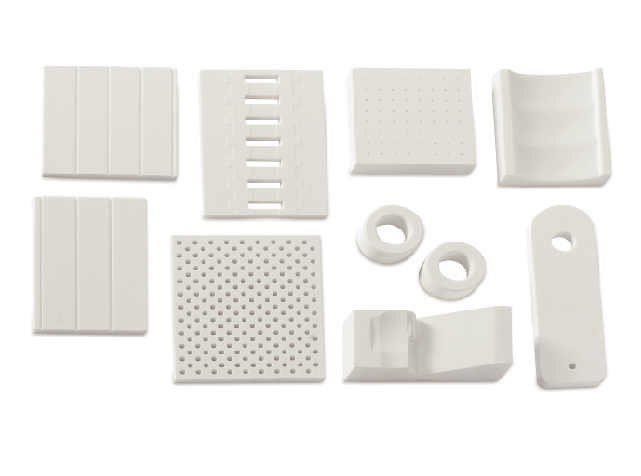

Ceramic furnace setters are engineered to support and protect metal parts during the high-temperature sintering process. These setters, crafted from advanced ceramic materials, are designed to withstand extreme temperatures and prevent the deformation of parts. Their primary function is to ensure that each component receives uniform exposure to heat and atmosphere, a necessity for achieving consistent sintering outcomes across the entire batch of parts.

Enhancements in Material Science

Recent advancements in ceramic technology have significantly enhanced the performance of furnace setters. Innovations in material composition and manufacturing techniques have resulted in setters that offer superior thermal stability, minimal thermal expansion, and exceptional resistance to thermal shock. These properties ensure that the setters maintain their structural integrity and dimensional accuracy even under the extreme conditions of the sintering furnace, leading to improved quality of the final metal parts.

Design Innovations for Improved Efficiency

Innovative design approaches to ceramic furnace setters have led to improved sintering efficiency and part quality. Customizable designs that cater to specific part geometries and sintering requirements have become possible, allowing for optimized heat flow and more efficient use of furnace space. Additionally, the development of setters with enhanced surface properties can reduce the sticking of metal parts, minimizing defects and improving release characteristics. This not only enhances the quality of the finished product but also reduces downtime for cleaning and maintenance, further boosting manufacturing efficiency.

Environmental Impact and Sustainability

The evolution of ceramic furnace setters also aligns with the growing emphasis on environmental sustainability in manufacturing. Advanced ceramics can be engineered to have a lower environmental impact, both in terms of the resources used to produce them and their efficiency during use. By enabling more efficient sintering processes, these setters contribute to reducing energy consumption and greenhouse gas emissions, marking a step forward in the sustainable manufacturing practices within the powder metallurgy industry.

Elevating Powder Metallurgy to New Heights

The introduction of innovative ceramic furnace setters is elevating powder metallurgy manufacturing to new heights. By improving the uniformity and efficiency of the sintering process, these setters are enabling the production of metal parts with enhanced mechanical properties, tighter tolerances, and higher quality standards. This is particularly crucial in industries where precision and reliability are paramount, such as aerospace, automotive, and medical devices.

Moreover, the flexibility and adaptability of modern ceramic furnace setters are opening up new possibilities in powder metallurgy. Custom and complex part designs, once considered challenging or impossible to manufacture through traditional methods, are now achievable. This not only expands the application range of powder metallurgy but also encourages innovation and creativity in part design.

Conclusion

Ceramic furnace setters are at the forefront of redefining powder metallurgy processes, providing innovative solutions that enhance efficiency, quality, and sustainability. As material science and manufacturing technologies continue to advance, the role of these critical components in the sintering process is set to become even more significant. By ensuring uniform heat distribution and offering customizable design options, ceramic furnace setters are instrumental in pushing the boundaries of what is possible in powder metallurgy, paving the way for the production of high-quality metal parts for a wide range of applications.

Leave a Reply