Innovations in Biomedical Instrument Manufacturing using Ceramic Furnace Setters

In the rapidly advancing field of biomedical engineering, precision, reliability, and innovation are paramount. Biomedical instruments, ranging from surgical tools to diagnostic devices, play a crucial role in advancing medical diagnostics, treatments, and research. Behind the production of these essential instruments, advanced technologies like ceramic furnace setters are driving groundbreaking innovations, making it possible to manufacture instruments that meet the strict requirements of modern healthcare. In this blog, we explore the key role of ceramic furnace setters in biomedical instrument manufacturing and how these innovations are transforming healthcare services.

The Importance of Biomedical Instruments in Healthcare

Biomedical instruments are the backbone of modern healthcare, contributing to accurate diagnoses, minimally invasive surgeries, and precision treatments. From endoscopes and surgical lasers to imaging devices and laboratory equipment, biomedical instruments enable healthcare professionals to provide optimal care and improve patient outcomes.

The Complexity of Biomedical Instrument Manufacturing

The manufacturing of biomedical instruments is a highly specialized process that requires precision, durability, and adherence to stringent regulatory standards. Biocompatibility, sterilizability, and ergonomic design are just a few of the key considerations driving innovation in biomedical instrument manufacturing.

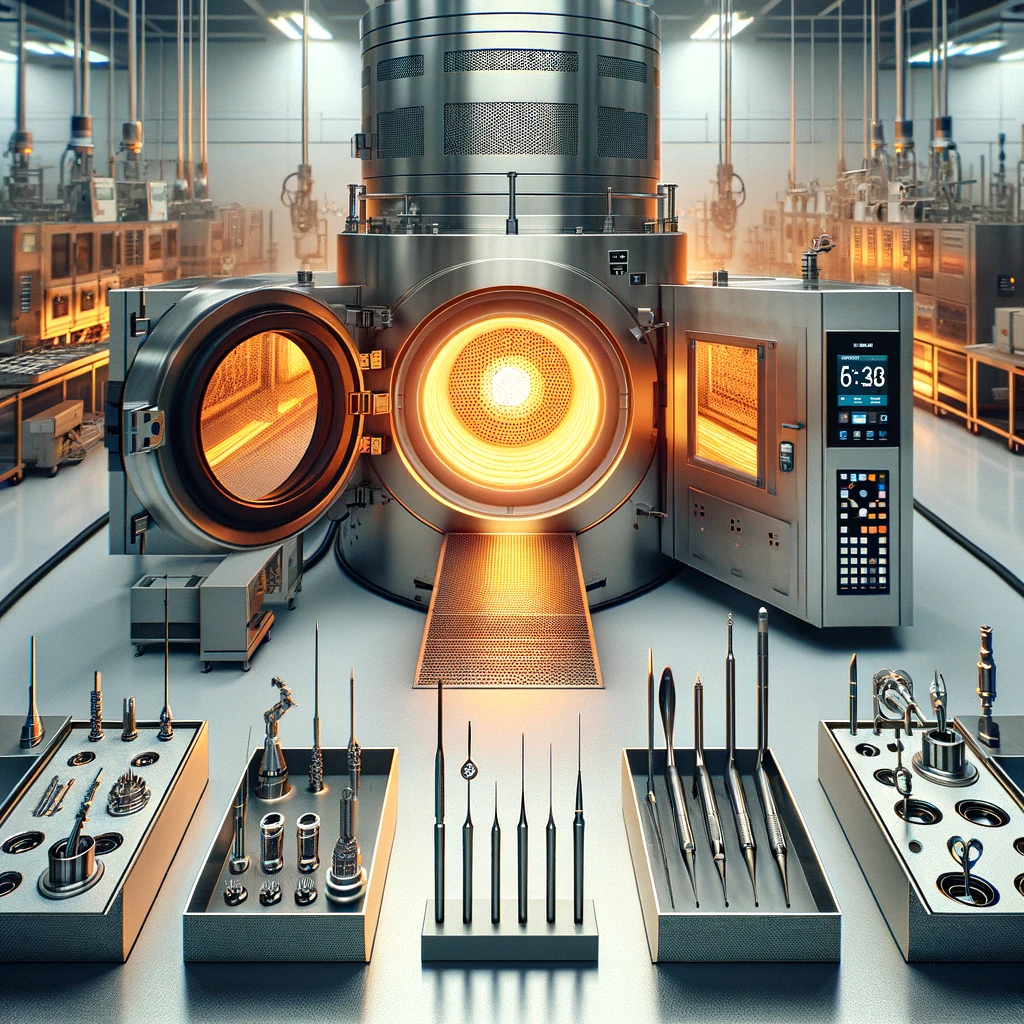

Transforming Biomedical Instrument Production with Ceramic Furnace Heating Devices

Ceramic furnace regulators made from high-quality materials like corundum-mullite and zirconia are revolutionizing the way biomedical instruments are produced:

- Precision Engineering: Ceramic furnace regulators can precisely control temperature gradients and heat distribution, ensuring that instrument components are uniformly heated and sintered. This precision is crucial for achieving the tight tolerances and dimensional accuracy required for biomedical instruments.

- Enhanced Durability: Ceramic furnace heating devices are ideal for the harsh conditions of biomedical instrument manufacturing due to their excellent thermal stability and resistance to thermal shock. These heating devices can withstand rapid heating and cooling cycles without deforming or degrading, ensuring reliable performance in clinical environments.

- Biocompatibility and Cleanliness: Ceramic furnace setters help improve the biocompatibility and cleanliness of biomedical instruments by minimizing the risk of contamination during the sintering process. Their inertness and high purity make them ideal for applications where precision and cleanliness are critical.

Driving Innovation in Biomedical Instrument Technology

The integration of ceramic furnace setters with biomedical instrument manufacturing processes is driving innovation across a broad range of application areas:

- Minimally Invasive Surgery: Biomedical instruments made with ceramic furnace heating devices enable minimally invasive surgeries, reducing patient discomfort, recovery time, and medical costs.

- Diagnostic Accuracy: Precision-designed instruments sintered with the help of ceramic furnace setters enhance the accuracy and reliability of diagnostic tests, allowing healthcare professionals to make informed decisions about patient care.

- Advancements in Treatment: Biomedical instruments play a critical role in providing targeted treatments and interventions, from cancer therapies to neurological diseases. The precision and reliability of instruments made with ceramic furnace setters contribute to the success of these treatment advancements.

Embracing the Future of Biomedical Instrument Manufacturing

The integration of advanced technologies such as ceramic furnace setters signals the arrival of a new era of innovation and progress in biomedical engineering. By harnessing the capabilities of these cutting-edge tools, biomedical manufacturers can create instruments that push the boundaries of precision, reliability, and performance, ultimately transforming the way healthcare is delivered and experienced.

Looking ahead, the synergy between advanced materials, innovative technologies, and the expertise of biomedical engineers is expected to open new possibilities in patient care, medical research, and healthcare innovation. Ceramic furnace setters stand at the forefront of this revolution, and the journey toward a healthier, more sustainable future in healthcare begins today.

Leave a Reply