How Are Silicon Carbide Saggers Made? A Behind-the-Scenes Look

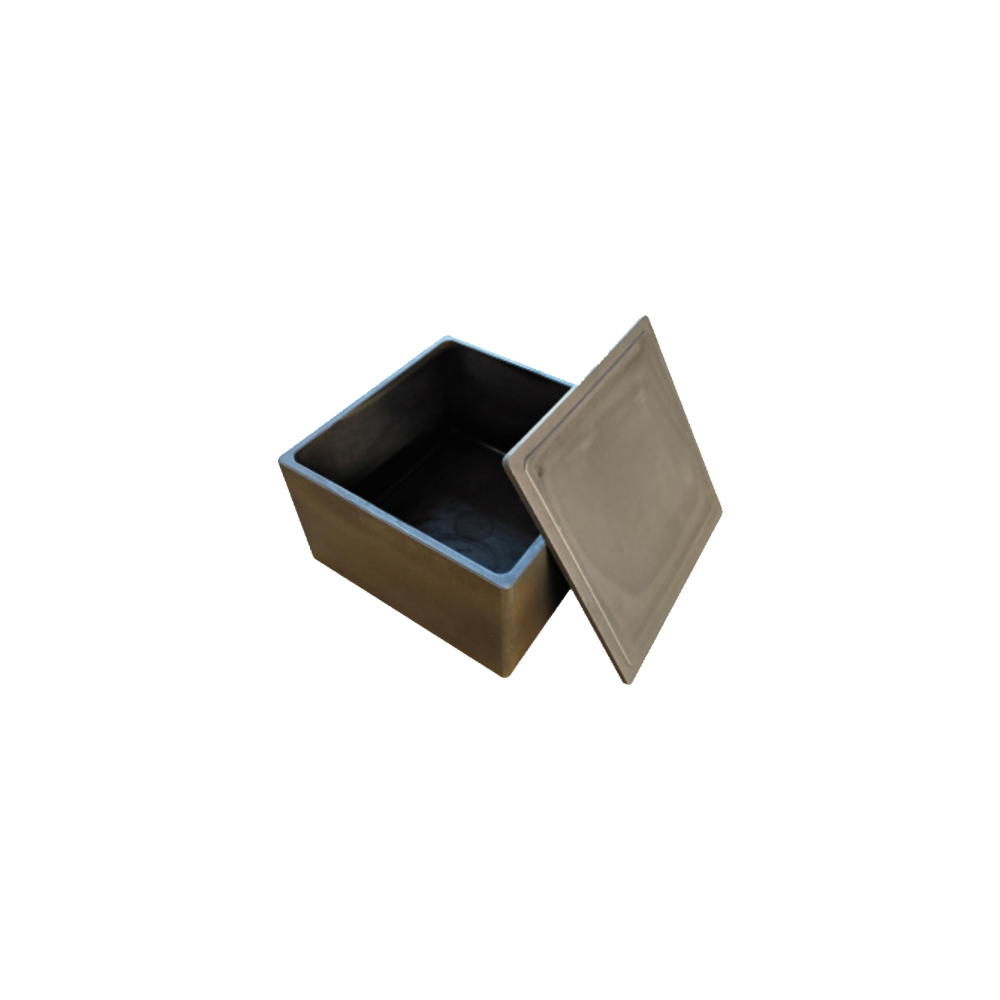

In high-temperature industries, Silicon Carbide saggers have become essential for sintering and calcination processes thanks to their excellent thermal, mechanical, and chemical performance. But how exactly are these high-performance refractory containers made?

Understanding the manufacturing process of SiC saggers provides deeper insight into their superior performance and cost structure. In this article, we’ll break down the materials, shaping methods, bonding types, and firing techniques that go into creating these vital components.

-

Raw Materials: The Foundation of Performance

The quality of a SiC sagger begins with its raw materials. These primarily include:

Silicon Carbide Powder (α-SiC)

Typically 98–99% pure, with particle sizes ranging from fine (<1μm) to coarse (>100μm), depending on the desired density and strength.

Binders and Additives

Organic or inorganic binders such as polyethylene glycol (PEG), phenolic resins, or silicates are added to aid formability and green strength.

Sintering Aids

In the case of pressureless sintered SiC (SSiC), additives like boron or aluminum may be used to enhance densification.

The particle size distribution, purity, and morphology of SiC powder significantly affect the final product’s density, porosity, and thermal shock resistance.

-

Shaping Techniques: Forming the Green Body

Once the raw material mix is ready, it must be shaped into the desired sagger geometry. Common shaping methods include:

- Isostatic Pressing

Provides uniform density

Ideal for medium to large sagger production

High mechanical strength and minimal defects

- Slip Casting (for Complex Shapes)

Involves pouring a SiC slurry into porous molds

Suitable for thinner-walled or intricate Silicon Carbide Saggers

Lower mechanical strength than pressed ones

- Extrusion or Uniaxial Pressing

Good for simple, mass-produced shapes

Cost-effective for standard sizes

May lead to density gradients if not well-controlled

After shaping, the “green body” is dried to remove excess moisture or solvent before sintering.

-

Bonding Methods: How the SiC Particles Hold Together

The type of bonding defines both the thermal performance and cost structure of the final product. There are three main types:

- Reaction-Bonded SiC (RB-SiC)

Made by infiltrating a porous SiC preform with molten silicon at ~1400–1500°C

Silicon reacts with carbon to form more SiC, creating a strong bond

Lower shrinkage and near-net shaping possible

Some residual free silicon remains, which can affect corrosion resistance

- Pressureless Sintered SiC (SSiC)

Achieved at ~2000°C without external pressure

Requires sintering aids like B or Al

Produces very high-density (>98%) material

No residual silicon → better purity, corrosion resistance

More expensive due to higher energy and process requirements

- Nitride-Bonded SiC (NB-SiC)

Involves reacting SiC with nitrogen to form Si₃N₄ bonds

Moderate strength, good oxidation resistance

Used in some lower-temperature or gas-fired kiln applications

Each bonding method serves different application needs. For high-purity lithium battery cathode materials, SSiC or high-quality RB-SiC are preferred. For lower-cost, general-purpose use, NB-SiC may suffice.

-

Sintering: Turning Powder into Stone

Once the green body is formed and dried, it undergoes sintering—a high-temperature treatment that densifies the structure and bonds the particles.

Key Parameters in Sintering Include:

Temperature Range: 1400–2200°C depending on bonding type

Atmosphere: Argon, nitrogen, or vacuum to prevent oxidation

Heating Rate: Controlled to avoid thermal shock

Soaking Time: Typically 2–8 hours at peak temperature

The sintering process must be carefully monitored to achieve high density while minimizing cracking, warping, or grain growth.

-

Post-Sintering Processes

After firing, some saggers may undergo:

Machining or Grinding for dimensional precision

Surface Coating to enhance oxidation resistance

Inspection and Quality Control, including thermal cycling tests, dimensional checks, and density measurements

High-end applications often require precision tolerances and strict quality testing, especially in electronics or battery industries.

Conclusion: The Craft Behind Every Sagger

The manufacturing of Silicon Carbide saggers is a blend of materials science, mechanical engineering, and thermal expertise. Every step—from powder selection to shaping and sintering—directly influences the sagger’s performance in high-stakes environments.

Whether you are a kiln operator, material scientist, or procurement manager, understanding how SiC saggers are made helps you appreciate their value and identify the right specifications for your application.

Investing in a high-quality, well-manufactured SiC sagger may come at a higher upfront cost—but the benefits in lifespan, process stability, and product yield can far outweigh the difference over time.

Leave a Reply