Future Trends and Technological Outlook for Corundum-Mullite Refractory Materials

As global industries continue evolving toward higher energy efficiency, material purity, and process precision, the role of advanced refractory materials becomes increasingly critical. Among these, corundum-mullite ceramics stand out for their excellent balance of thermal resistance, mechanical integrity, and affordability. Widely used in kilns, furnaces, and high-temperature components, corundum-mullite refractories are at the forefront of thermal materials science.

This article explores the future development trends, market demands, and emerging technologies shaping the next generation of corundum-mullite refractory products.

-

Market Drivers: Why Innovation Is Necessary

Several global trends are reshaping the landscape for refractory materials:

Electrification of kilns and furnaces: Requires materials with lower thermal mass and faster heat-up capabilities

Battery material sintering (e.g., LFP, NCM): Demands high chemical inertness and repeatable performance

Decarbonization pressure: Drives demand for longer-lasting, energy-saving kiln furniture

Automation and precision manufacturing: Requires tighter dimensional control and reliability

Green manufacturing and recycling: Pushes for sustainable sourcing and recyclability

In this context, traditional corundum-mullite formulations must evolve to meet new thermal, chemical, and environmental challenges.

-

Material Innovations: Enhanced Composition Engineering

- Fine-Grained and Nano-Structured Composites

Advances in raw material processing now allow for the production of ultrafine α-Al₂O₃ and SiO₂ powders, which improve sintering behavior and microstructural uniformity. These offer:

Higher density

Improved mechanical strength

Better resistance to thermal cycling

Nano-reinforced corundum-mullite, incorporating nano-ZrO₂ or TiO₂, is a promising area for boosting fracture toughness and thermal shock resistance.

- Low-Impurity Formulations

As sintered products become more sensitive to contamination—especially in electronics and energy storage—the demand for ultra-low impurity refractory grades is rising. Purity levels of ≥99.5% alumina, combined with ultra-clean mullite, are being developed to meet these standards.

-

Process Technology Trends

- Additive Manufacturing (3D Printing)

While still in its early stages, 3D printing of refractory ceramics is gaining traction. For corundum-mullite materials, this technology can offer:

Complex geometries (e.g., lattice structures for weight reduction)

Rapid prototyping of customized kiln furniture

Reduced material waste and tooling cost

Binders and slurries compatible with corundum-mullite are under active development for binder jetting and stereolithography techniques.

- Pressure-Assisted Sintering

Traditional sintering requires high temperatures (~1,600 °C) and long dwell times. Future trends include:

Hot isostatic pressing (HIP): Achieves higher densities at lower temperatures

Spark plasma sintering (SPS): Rapid sintering with improved grain boundary control

These processes improve the mechanical strength and lifetime of corundum-mullite products, especially in load-bearing applications.

-

Functional Surface Engineering

- Anti-Sticking and Glazing Technologies

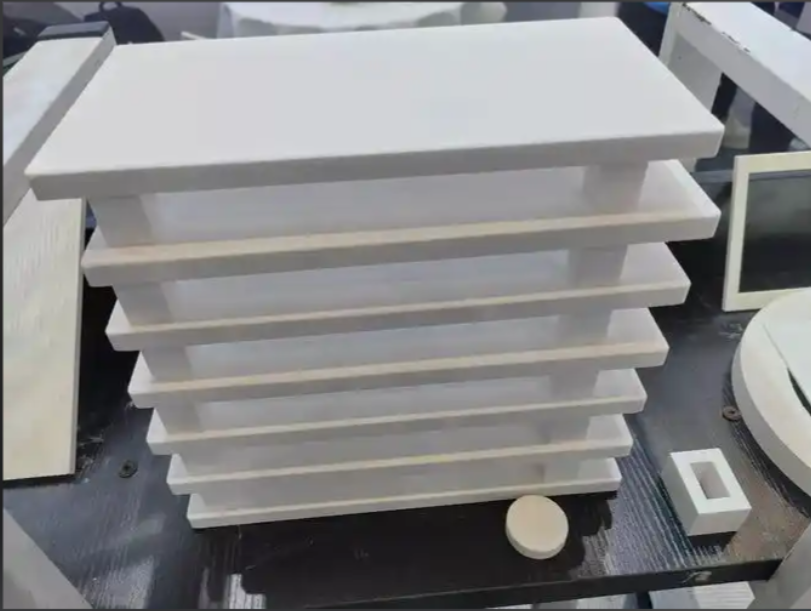

Surface coatings such as MgO-, Y₂O₃-, or ZrO₂-based glazes help reduce material sticking and contamination during high-temperature processing. These are increasingly applied to setter plates, saggers, and kiln shelves.

Next-generation coatings are being designed to:

Resist aggressive vapors (e.g., lithium, fluorides)

Improve cleaning efficiency

Extend service life in powder sintering applications

- Thermal Barrier Coatings (TBCs)

Multi-layer ceramic coatings can act as thermal insulators or chemical shields, further enhancing sagger performance in extreme environments.

-

Sustainability and Circular Economy

Future corundum-mullite products must also align with circular economy principles:

Recycling spent kiln furniture: Crushing and reusing high-purity aggregates

Eco-friendly binders: Moving away from boron and phosphate binders to cleaner alternatives

Energy-saving designs: Hollow and lightweight structures to reduce thermal mass

Sustainability will not only be a regulatory requirement but also a competitive advantage in global refractory markets.

-

Digital Integration and Smart Monitoring

The integration of digital technologies into refractory applications is a growing trend:

RFID tracking: Enables lifecycle monitoring of individual saggers and plates

Infrared imaging and sensors: Help monitor hot-spot development, crack formation, and early failure

Data-driven maintenance: AI models can predict when a corundum-mullite component is likely to fail based on usage patterns

Such tools enable predictive maintenance, lower downtime, and better asset management.

-

Application Expansion and Market Outlook

In addition to ceramics and metallurgy, emerging fields are creating new opportunities for advanced corundum-mullite materials:

| Sector | Potential Application |

| Solid-state batteries | High-purity saggers for oxide electrolyte sintering |

| Green hydrogen production | High-temp reactors and insulation linings |

| Aerospace ceramics | Thermal barrier structures and support trays |

| Semiconductor packaging | Ultra-clean sintering under vacuum or reducing atmospheres |

Market forecast:

According to industry analysts, the global market for advanced refractories—including corundum-mullite—is expected to grow at ~5–6% CAGR through 2030, driven by electronics, energy materials, and sustainable manufacturing trends.

Conclusion

Corundum-mullite refractory materials, once considered standard ceramic components, are now entering a new era of technological sophistication. With innovations in material purity, manufacturing, coating technologies, and digital integration, they are evolving into engineered systems optimized for modern high-performance applications.

Manufacturers who invest in R&D and embrace these future trends will be well-positioned to meet the growing demands of advanced sintering industries—from magnetic materials to battery electrodes and beyond.

Corundum-mullite’s future lies in customization, integration, and smart engineering—offering not only resilience under extreme temperatures but also a platform for innovation in sustainable, efficient, and precision-driven thermal processing.

Leave a Reply