From Powder to Product: Forming and Sintering Technologies for Aluminum Nitride Refractories

Aluminum nitride (AlN) has rapidly ascended in the world of advanced ceramics and refractory materials, owing to its exceptional thermal conductivity, chemical stability, and electrical insulation. However, the key to unlocking these properties in real-world applications lies not only in its chemistry, but also in the engineering of AlN from powder to final product.

The manufacturing of AlN-based refractory components involves a highly controlled combination of powder processing, forming, and sintering techniques. In this article, we explore the current state of AlN forming and densification methods, the challenges they address, and the emerging innovations reshaping this critical field.

- Challenges in Processing Aluminum Nitride

Before delving into techniques, it’s important to understand the processing challenges that set AlN apart from other ceramics:

| Challenge | Explanation |

| Oxygen contamination | Even small amounts of oxygen can degrade thermal conductivity by forming Al₂O₃ at grain boundaries. |

| High sintering temperature | Pure AlN requires sintering at >1800 °C, making densification difficult. |

| Moisture sensitivity | AlN hydrolyzes in water, releasing ammonia and forming hydroxides—complicating aqueous processing. |

| Grain growth control | Uniform microstructure is essential to maintain mechanical and thermal properties. |

Thus, each step from powder synthesis to final product must be carefully engineered to maintain purity, density, and performance.

- Powder Preparation: The Foundation of Quality

The properties of AlN ceramics start with the quality of the raw powder. Common synthesis methods for AlN powder include:

Carbothermal Reduction and Nitridation (CRN):

Alumina + carbon → AlN + CO (in N₂ atmosphere at 1500–1700 °C)

Cost-effective, but results in irregular particle morphology and some oxygen impurities.

Direct Nitridation of Aluminum:

Fine aluminum powder reacts with nitrogen gas to form AlN at ~1000–1200 °C.

Produces purer AlN but requires careful control to avoid passivation and incomplete conversion.

Chemical Vapor Deposition (CVD):

High purity, nano-sized particles ideal for electronic applications, though expensive for bulk refractory use.

To optimize performance in refractory components, powders are often milled to achieve uniform particle size (~1–5 μm) and treated with sintering aids such as Y₂O₃, which promote densification without excessive grain growth.

- Forming Techniques for AlN-Based Components

The choice of forming method depends on the desired geometry, mechanical strength, and application environment of the final product.

- Uniaxial and Isostatic Pressing

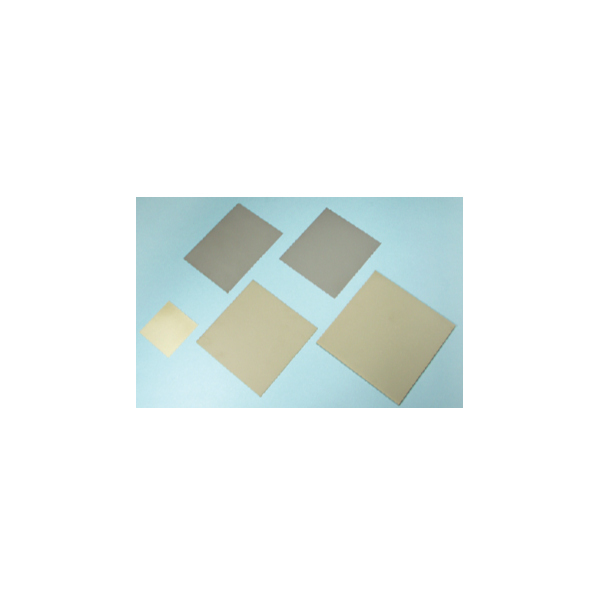

Suitable for simple geometries such as crucibles, rods, or plates.

Isostatic pressing (CIP) offers superior green density and uniformity.

Requires precise control of binder systems due to AlN’s hydrolysis sensitivity.

- Injection Molding

Used for producing complex shapes like intricate nozzles or thermal interface components.

Feedstock consists of AlN powder mixed with thermoplastic binders.

Green parts undergo debinding and sintering in controlled atmospheres.

- Tape Casting and Lamination

Ideal for thin sheets or multilayer substrates.

Uses organic solvents (non-aqueous) to prevent AlN degradation.

Laminated and hot-pressed to achieve final shapes with embedded features.

- Additive Manufacturing (3D Printing)

Emerging methods like stereolithography (SLA) and binder jetting allow custom geometries and internal features.

Research is ongoing into developing printable AlN pastes and achieving sufficient sintered density.

- Sintering: Turning Green Bodies into Dense Ceramics

The most critical step in AlN fabrication is sintering, where powder compacts are densified into solid, load-bearing ceramics.

- Pressureless Sintering

Requires high temperatures (>1800 °C) and sintering aids (typically 1–5 wt% Y₂O₃).

Conducted in nitrogen or argon atmospheres to prevent decomposition.

Produces good density (>97%) but may lead to exaggerated grain growth if not controlled.

- Hot Pressing

Uniaxial pressure applied during sintering (typically 20–40 MPa).

Enables lower sintering temperatures (~1700–1750 °C) and finer microstructures.

Suitable for high-performance AlN components in electronics and thermal systems.

- Spark Plasma Sintering (SPS)

Rapid sintering using pulsed DC current and pressure.

Offers short cycle times, fine grain size, and excellent mechanical properties.

Increasingly used in research and prototype applications.

| Method | Temp (°C) | Pressure | Atmosphere | Key Benefit |

| Pressureless Sintering | >1800 | None | N₂ | Scalable for large parts |

| Hot Pressing | ~1700–1750 | 20–40 MPa | N₂ | High density, low porosity |

| SPS | ~1500–1650 | 30–100 MPa | Vacuum or N₂ | Rapid densification, fine microstructure |

- Post-Processing and Surface Engineering

Post-sintering operations enhance dimensional accuracy and surface performance:

Diamond grinding or machining: Required due to AlN’s hardness (~9 on Mohs scale)

Surface coatings (e.g., Al₂O₃ or Si₃N₄): Provide protection against hydrolysis

Polishing: For optical or electronic components where low surface roughness is essential

Proper post-processing ensures longer service life, especially in corrosive or humid environments.

- Trends and Future Directions

- Near-Net-Shape Manufacturing

To reduce waste and machining cost, industries are shifting toward net-shape forming (e.g., injection molding, AM) for AlN refractory parts.

- Grain Boundary Engineering

Optimizing grain boundary chemistry—through dopants or controlled atmosphere sintering—improves thermal conductivity and mechanical strength.

- Hybrid Sintering Methods

Combining techniques (e.g., hot pressing + microwave sintering) enables fine control over microstructure evolution and property tuning.

Conclusion

From raw powder to precision-engineered refractory components, the processing of aluminum nitride is a complex but critical journey. With continued innovation in forming, sintering, and post-processing, AlN is moving beyond high-tech electronics and into broader refractory applications where thermal management, mechanical resilience, and chemical stability are paramount.

As fabrication technologies mature and costs decrease, we can expect to see more widespread adoption of AlN ceramics in metallurgy, aerospace, power systems, and beyond—transforming how heat is managed in some of the world’s most demanding environments.

Leave a Reply