Environmental Impact and Sustainability: Production and Application of Corundum Mullite

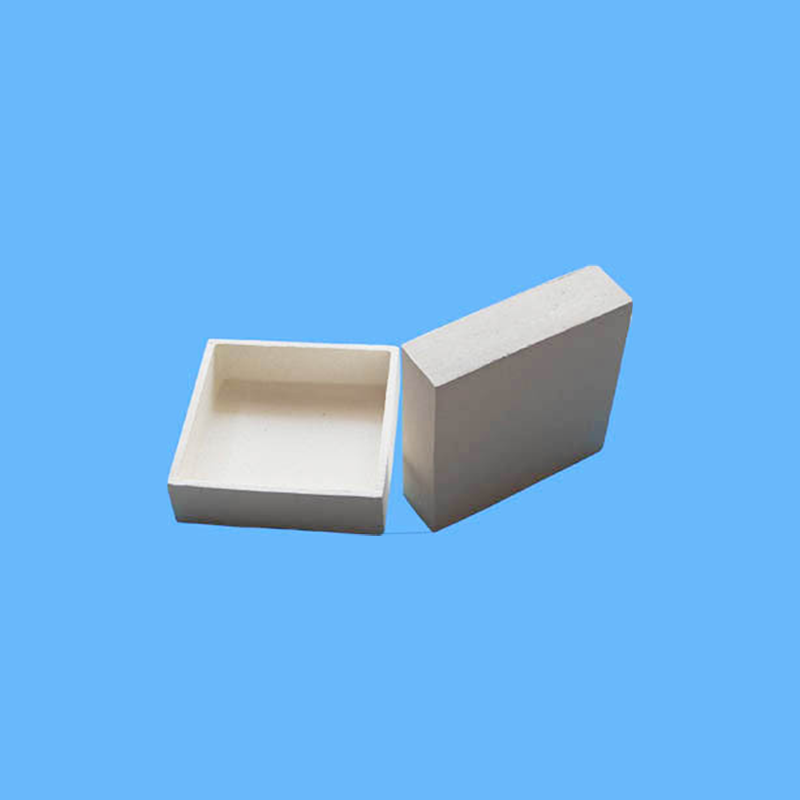

As global attention to sustainable development increases, the refractory materials industry faces significant environmental challenges. In this context, corundum mullite (3Al₂O₃·2SiO₂), an important refractory material, must balance performance with environmental friendliness, a pressing issue for the industry.

Environmental Impact of Corundum Mullite

The production of corundum mullite involves several steps, including raw material extraction, sintering, and post-processing. While this material excels in refractory performance, its production process has noteworthy environmental impacts.

Raw Material Extraction

The primary raw materials for corundum mullite are bauxite and silica sand. Extracting these minerals can lead to ecological destruction, soil erosion, and a decline in biodiversity. Additionally, the development of mining sites can adversely affect surrounding communities, leading to soil contamination and reduced water availability. Dust and noise generated during mining can also disrupt the quality of life for nearby residents.

Energy Consumption

The high-temperature sintering process is the most energy-intensive step in production. Studies show that sintering temperatures typically range from 1400°C to 1600°C, requiring substantial fuel (such as coal, natural gas, or electricity), which results in greenhouse gas emissions that exacerbate global warming. The high energy consumption also subjects companies to rising energy costs, adding to economic burdens.

Waste Generation

In addition to the main product, the production process often generates a significant amount of by-products and waste. If not properly managed, these wastes can contaminate soil and water bodies. Particularly concerning is the potential leaching of heavy metals and chemicals, which can lead to long-term environmental pollution and negatively impact ecosystem health.

Sustainable Development Strategies

To address environmental challenges, the production and application of corundum mullite must consider sustainability. Here are several effective strategies:

Sustainable Raw Material Extraction

Companies should adopt environmentally friendly raw material extraction methods, such as small-scale, controlled mining practices that minimize ecological disruption. Developing alternative materials, such as utilizing industrial by-products (like aluminum dross from electrolytic aluminum production), can reduce dependence on natural resources. Through technological innovation, companies can optimize raw material use and improve recycling rates.

Energy Optimization

Production facilities can enhance energy efficiency by implementing advanced combustion systems and heat recovery systems to reduce energy consumption. Utilizing renewable energy sources (such as solar and wind energy) instead of traditional fossil fuels can significantly decrease greenhouse gas emissions. Additionally, companies can adopt energy management systems to monitor and optimize energy usage, lowering energy consumption throughout the production process.

Waste Management and Recycling

By developing new technologies, companies can recycle waste generated during production. For example, waste materials can be reused in other refractory product manufacturing or as construction materials, minimizing waste output. Companies can collaborate with other industries to share resources and technologies, achieving broader circular economy goals.

Green Certification and Standards

Encouraging companies to obtain green production certifications, such as ISO 14001 environmental management system certification, can enhance corporate image and promote investment in sustainable development. Green certification can also open new market opportunities by attracting customers who prioritize environmental responsibility.

Case Study

Some companies have already implemented sustainable development strategies in the production of corundum mullite. For instance, a well-known refractory materials company successfully reduced its energy consumption by 30% by introducing new technologies and processes. By optimizing production workflows, the company not only improved efficiency but also reduced production costs. Additionally, waste recycling initiatives led to a 50% reduction in waste generated during production. These measures not only enhanced the company’s competitiveness but also garnered market recognition, establishing a positive corporate image.

Conclusion

As an essential refractory material, the environmental impact of corundum mullite’s production and application cannot be overlooked. By adopting sustainable development strategies, companies can minimize environmental burdens while gaining a competitive edge in a challenging market. With advancements in technology and increasing environmental awareness, we look forward to seeing more eco-friendly and efficient corundum mullite products that contribute to the sustainable development of industry.

In the global pursuit of a sustainable future, producers of Application of corundum mullite must take on the responsibility of achieving a balance between economic growth and environmental protection. Through innovation and continuous improvement, corundum mullite can not only continue to provide high-quality refractory materials across various industries but also become a leader in environmental stewardship. This approach will lay a solid foundation for meeting current industrial needs while ensuring sustainable development for the future.

Leave a Reply