Elevating Quality Standards: Ceramic Furnace Setters' Impact on Powder Metallurgy Manufacturing

The world of manufacturing is continually evolving, with innovations that push the boundaries of quality and efficiency. In the specialized field of powder metallurgy, where precision-engineered components are created from powdered metal materials, the quest for excellence is relentless. A key player in this quest is the ceramic furnace setter, a seemingly modest yet critical tool that significantly impacts the quality of the manufacturing process. This blog explores the transformative role of ceramic furnace setters in powder metallurgy manufacturing and how they are elevating quality standards to new heights.

The Crucial Role of Ceramic Furnace Setters

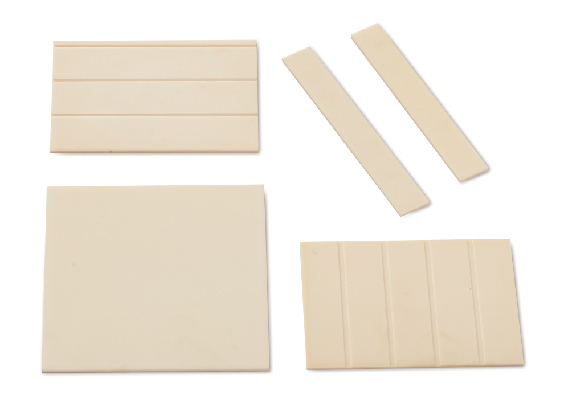

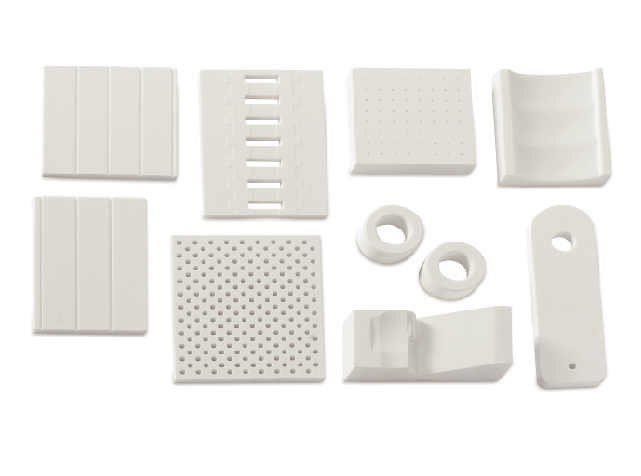

Ceramic furnace setters are designed to withstand extreme temperatures and environments, making them ideal for the powder metallurgy sintering process. This process involves heating compressed metal powders to just below their melting points, causing the particles to fuse into a solid piece. Ceramic setters play a vital role in this phase, providing a stable and heat-tolerant surface upon which the metal powders can be sintered. Their performance directly affects the heat distribution, atmospheric control, and ultimately, the quality of the final product.

Enhancing Heat Distribution and Consistency

One of the primary benefits of advanced ceramic furnace setters is their ability to enhance heat distribution and consistency. Uniform heat is paramount in achieving consistent sintering across all parts, ensuring each component meets the desired mechanical and physical properties. Innovative ceramic materials and design improvements have led to setters that offer superior thermal conductivity and heat retention, reducing hotspots and thermal gradients. This uniformity is crucial for parts demanding high precision and strength, directly translating to higher quality standards in finished products.

Improving Atmospheric Control

Powder metallurgy manufacturing often requires specific atmospheric conditions to prevent oxidation and contamination of the sintered parts. Ceramic furnace setters contribute significantly to maintaining these controlled environments. Their material composition can be engineered to resist reactions with various gases at high temperatures, ensuring a pure sintering atmosphere. This control is vital for producing components with specific properties, such as corrosion resistance, required in aerospace, medical, and automotive applications.

Reducing Deformation and Enhancing Dimensional Stability

The integrity of a sintered component’s shape and dimensions is critical for parts that must fit precisely within mechanical assemblies. Ceramic furnace setters help to reduce deformation during the sintering process by providing a rigid, flat surface that supports the parts under the influence of heat. Advances in ceramic technology have led to materials that minimize interaction between the setter and the part, further enhancing dimensional stability. This precision is crucial for the manufacture of components with tight tolerances and complex geometries.

Extending Equipment Life and Reducing Costs

The durability and longevity of ceramic furnace setters not only improve the quality of sintered components but also extend the life of sintering equipment. High-quality setters are less prone to wear, thermal shock, and degradation, reducing the frequency of replacements and maintenance downtime. This durability translates to cost savings and increased efficiency in manufacturing operations, allowing for a more consistent production quality over time.

Conclusion

Ceramic furnace setters are at the heart of elevating quality standards in powder metallurgy manufacturing. Their impact on heat distribution, atmospheric control, dimensional stability, and overall equipment efficiency is profound. As advancements in ceramic materials and manufacturing technologies continue, the potential for further quality enhancements in powder metallurgy is vast. These humble yet powerful tools exemplify how innovation in even the most fundamental components of manufacturing can lead to significant improvements in product quality. As the industry moves forward, the role of ceramic furnace setters in achieving and surpassing quality standards will undoubtedly grow, marking a new era of precision and excellence in powder metallurgy manufacturing.

Leave a Reply