Corundum-Mullite: The Unsung Hero of High-Temperature Refractory Materials—An Industrial Application Analysis

In high-temperature industrial applications, the refractory properties of materials determine the stability and efficiency of production. Among various high-temperature refractory materials, corundum-mullite (Corundum-Mullite) has become an important composite material due to its excellent thermal stability, mechanical strength, and resistance to chemical corrosion. While it may not be as well-known as some other materials, it undoubtedly plays a crucial role as an “unsung hero” in the realm of high-temperature refractories.

From steelmaking to aerospace technologies, to various high-temperature metallurgical equipment, corundum-mullite demonstrates significant potential. This article will explore its applications in refractory materials and highlight the critical role it plays in high-temperature environments.

-

Basic Properties of Corundum-Mullite

Before delving into its applications, let’s first understand the fundamental properties of corundum-mullite. Corundum-mullite is a composite material composed of corundum (Al₂O₃) and mullite (3Al₂O₃·2SiO₂), and it has the following remarkable characteristics:

- High-Temperature Resistance: Corundum-mullite has a melting point above 1850°C, which allows it to maintain its physical properties in extreme high-temperature environments.

- Thermal Shock Resistance: It has excellent resistance to thermal shock, able to withstand the stresses induced by rapid temperature changes without cracking.

- Mechanical Strength: Even at high temperatures, corundum-mullite maintains relatively high compressive strength and hardness, making it suitable for use in high-temperature equipment that experiences heavy loads.

- Chemical Stability: It demonstrates excellent resistance to acids, alkalis, and oxidation, making it highly durable against chemical corrosion.

- Low Thermal Expansion: It has a low coefficient of thermal expansion, which helps prevent thermal stress-induced damage during temperature fluctuations.

These superior properties make corundum-mullite an ideal candidate for a wide range of applications in refractory materials.

-

Applications of Corundum-Mullite in Steelmaking

The steel industry is one of the most significant areas where corundum-mullite is applied. In steelmaking, furnace linings need to withstand extremely high temperatures and harsh chemical environments, and corundum-mullite, with its excellent thermal stability and thermal shock resistance, has become an ideal material for these applications.

-

High-Temperature Furnace Linings

In steelmaking, especially in blast furnaces and electric arc furnaces, the lining material must endure temperatures exceeding 1600°C. Corundum-mullite’s high melting point and excellent thermal stability make it an ideal choice for these linings. Compared to traditional alumina-based refractories, corundum-mullite maintains its shape and structure at higher temperatures, reducing material loss due to thermal shock or chemical reactions.

-

Smelting Furnace Refractory Bricks

In the steel production process, smelting furnaces are subjected to high temperatures for prolonged periods. Corundum-mullite bricks offer superior thermal expansion properties, thermal shock resistance, and corrosion resistance, making them an excellent material for furnace linings. These bricks improve steelmaking efficiency and extend the service life of the furnaces.

-

Steel Casting Molds

During steel casting, molds must withstand the high temperatures of molten steel and chemical corrosion. Corundum-mullite’s thermal shock resistance and chemical stability make it an essential material for casting molds, especially in precision casting processes, where longer mold life and higher casting accuracy are crucial.

III. Applications of Corundum-Mullite in the Ceramic Industry

Corundum-mullite also plays an important role in the ceramic industry, particularly in high-temperature kilns and firing furnaces. Its excellent heat resistance and thermal expansion properties make it an essential material in ceramic firing processes.

-

Ceramic Kiln Linings

In ceramics manufacturing, firing temperatures often exceed 1300°C. Corundum-mullite can not only withstand extreme temperatures but also resist high-temperature gases and chemical corrosion inside kilns, extending the kiln’s lifespan. Its low thermal expansion properties help prevent thermal stress-related damage during the firing process.

-

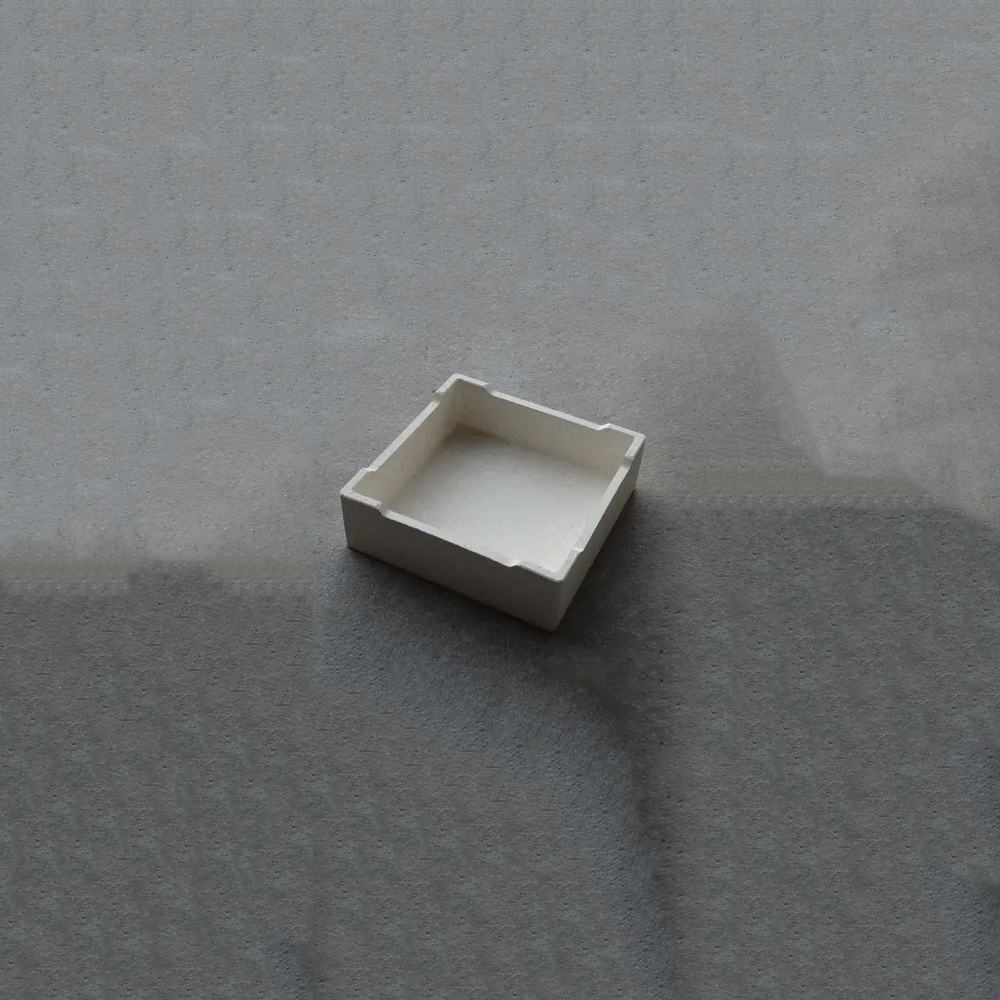

High-Temperature Ceramics

Corundum-mullite is widely used in the production of high-temperature ceramic products, especially in making furnaces, ceramic crucibles, and high-temperature electrical heating elements. Its strength and stability ensure that these ceramic products perform well in high-temperature environments and maintain a long service life.

- Applications of Corundum-Mullite in the Petrochemical Industry

The petrochemical industry requires refractory materials with extremely high durability, especially in oil refining units and catalytic cracking reactors, where corundum-mullite’s high-temperature resistance and chemical corrosion resistance make it an ideal material.

-

Catalytic Cracking Reactors

In petrochemical catalytic cracking processes, reactors are exposed to extremely high temperatures and corrosive media. Corundum-mullite, as a material with high temperature resistance and chemical stability, can enhance the performance of reactors and extend their lifespan. Its thermal shock resistance and stability make it highly suitable for the harsh, temperature-varying environments of reactors.

-

Oil Refining Furnaces

In oil refining, furnaces are subjected to high temperatures and aggressive chemical reactions. Corundum-mullite, with its excellent resistance to both high temperatures and corrosive substances, helps improve the performance and safety of these furnaces, contributing to more efficient refining processes.

-

Future Prospects of Corundum-Mullite

As industrial demands continue to rise, the applications of corundum-mullite are expected to expand even further. With the development of advanced high-temperature and ultra-high-temperature technologies, corundum-mullite has significant potential for applications in aerospace, nuclear energy, and space propulsion systems. In particular, as high-temperature synthesis and new material fields continue to explore new possibilities, the properties of corundum-mullite could be further enhanced through doping or new processing techniques, meeting increasingly stringent performance demands.

Conclusion

Corundum-mullite, as a high-performance refractory material, plays an indispensable role in a wide range of high-temperature industrial applications. From steelmaking to petrochemical processes, to high-temperature kilns and ceramic industries, corundum-mullite offers outstanding performance. With the continuous advancement of science and technology, the future of corundum-mullite will see even greater potential in new and emerging fields, driving industrial progress and technological innovation.

Leave a Reply