Comparing Sintering Trays: Silicon Carbide, Graphite, and High-Purity Alumina

In materials engineering and manufacturing, the sintering process plays a critical role in achieving the desired performance of ceramic and metal parts. The choice of sintering tray material is a key factor that affects the quality, efficiency, and outcome of the sintering process. Silicon carbide, graphite, and high-purity alumina are three commonly used sintering tray materials, each with its unique advantages and challenges. This blog post will provide an in-depth comparison of these materials, helping you determine the best option for your specific sintering needs.

Silicon Carbide (SiC) Sintering Trays

Advantages:

- High Thermal Conductivity: SiC trays have the advantage of rapid heat dissipation, helping to achieve uniform temperature distribution within the tray, which is crucial for consistent sintering results.

- High-Temperature Strength: Silicon carbide maintains its structural integrity even at temperatures up to 1600°C, making it an ideal choice for high-temperature applications.

- Thermal Shock Resistance: Silicon carbide can withstand rapid temperature changes without cracking, a critical property for processes involving rapid heating and cooling cycles.

Disadvantages:

- Cost: Silicon carbide trays are generally more expensive than other materials, potentially increasing upfront costs.

- Wear: While durable, silicon carbide can gradually wear down in harsh environments, affecting its lifespan.

Graphite Sintering Trays

Advantages:

- High-Temperature Resistance: Graphite can withstand extremely high temperatures, exceeding most ceramic materials, and can endure temperatures up to 3650°C in inert environments.

- Thermal Shock Resistance: Graphite can handle rapid temperature changes, making it suitable for applications requiring fast thermal cycles.

- Machinability: Graphite is relatively easy to machine into complex shapes, offering flexibility in tray design.

Disadvantages:

- Oxidation: At high temperatures in oxidative atmospheres, graphite oxidizes. It can only be used in inert or reducing environments unless coated with a protective layer.

- Brittleness: Graphite has poor impact resistance and is prone to cracking or breaking under mechanical stress.

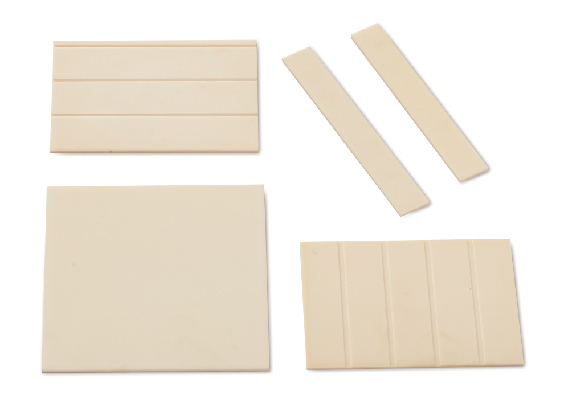

High-Purity Alumina (Al2O3) Sintering Trays

Advantages:

- Chemical Inertness: High-purity alumina is chemically inert in most sintering environments, preventing contamination of the processed materials.

- Thermal Stability: Alumina trays can withstand sustained high temperatures (up to 1750°C) and remain stable under various thermal conditions.

- Wear Resistance: Alumina has excellent wear and corrosion resistance, extending the tray’s lifespan.

Disadvantages:

- Thermal Conductivity: Compared to silicon carbide, alumina has a lower thermal conductivity, which leads to less uniform heat distribution.

- Cost and Manufacturing: High-purity alumina trays are expensive, and due to their hardness and brittleness, they are difficult to shape into complex forms.

Conclusion

When selecting between silicon carbide, graphite, and high-purity alumina sintering trays, specific application requirements such as temperature, atmosphere, thermal shock needs, and budget constraints should be considered. Silicon carbide trays are favored for their excellent thermal performance and flexibility in rapid-cycle applications. Graphite is the ideal choice for ultra-high-temperature applications in controlled atmospheres. High-purity alumina offers unparalleled chemical resistance and durability, making it suitable for long-term use in stable temperature environments.

By understanding the advantages and limitations of each material, manufacturers can choose the most suitable sintering tray to ensure optimal performance, efficiency, and product quality in their sintering operations. Whether using ceramics, metals, or other advanced materials, the right sintering tray material is the cornerstone of successful manufacturing outcomes.

![Silicon Carbide Board [MH-KX-SiC]](https://moatcity.com/wp-content/uploads/2024/10/1728636817408.png)

Leave a Reply