Choosing the Right Sintering Tray Material: Alumina vs. Zirconia vs. Silicon Carbide

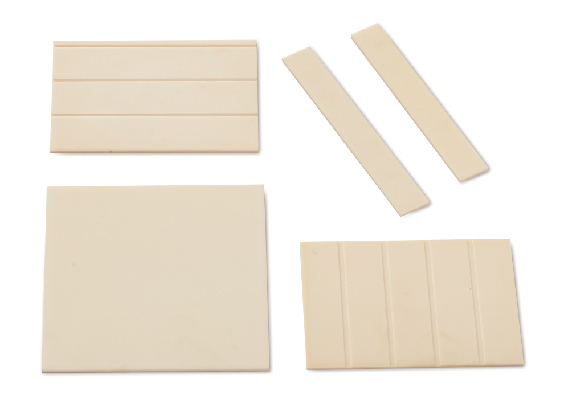

Introduction to Sintering Tray Materials

In manufacturing processes that involve sintering—whether for ceramics, metals, or polymers—the choice of tray material is crucial. The selected sintering tray material can significantly impact the efficiency, cost, and quality of the final product. In this article, we compare three commonly used sintering tray materials: Alumina (Al₂O₃), Zirconia (ZrO₂), and Silicon Carbide (SiC), with a particular focus on their performance at different heating rates.

Alumina (Al₂O₃) Trays

Advantages:

- Thermal Conductivity: Alumina has a thermal conductivity of approximately 20-30 W/mK, helping to distribute heat uniformly, which is essential for continuous sintering.

- High Melting Point: Alumina has a melting point of around 2072°C, making it capable of withstanding high sintering temperatures.

- Cost-Effectiveness: Compared to other advanced ceramics, alumina is more affordable, making it a popular choice for bulk applications.

Disadvantages:

- Thermal Shock Resistance: While alumina can withstand moderate temperature changes, it is not as effective as silicon carbide or zirconia in rapid thermal cycling.

- Strength and Toughness: Alumina has high strength but is less tough compared to zirconia and silicon carbide, which can be problematic during handling and under operational stresses.

Zirconia (ZrO₂) Trays

Advantages:

- Exceptional Thermal Shock Resistance: Zirconia performs excellently in environments with rapid temperature changes due to its low thermal conductivity (2-3 W/mK) and high toughness.

- Mechanical Properties: With high fracture toughness, zirconia resists cracking under stress, which is vital for trays exposed to mechanical forces during sintering.

- High Melting Point: Zirconia’s melting point exceeds 2700°C, making it suitable for high-temperature applications.

Disadvantages:

- Thermal Conductivity: The low thermal conductivity of zirconia enhances its thermal shock resistance but makes it challenging to achieve uniform heating.

- Cost: Due to its superior mechanical and thermal properties, zirconia is more expensive, which may limit its use in cost-sensitive applications.

Silicon Carbide (SiC) Trays

Advantages:

- Outstanding Thermal Conductivity: Silicon carbide boasts the highest thermal conductivity of the three materials, around 120-200 W/mK, providing excellent heat distribution.

- Thermal Shock Resistance: SiC excels in resisting thermal shock, making it ideal for rapid heating and cooling cycles, surpassing zirconia.

- High Melting Point and Strength: SiC can withstand temperatures above 2700°C and has strong mechanical strength.

Disadvantages:

- Brittleness: Despite its high strength, silicon carbide is brittle, which can be a drawback in applications requiring frequent handling or where the trays may be subjected to mechanical impacts.

- Cost: SiC is generally more expensive than alumina, reflecting its advanced performance characteristics.

Choosing the Right Material

The choice of sintering tray material should be guided by the specific needs of the application:

- For High-Speed Sintering: Silicon carbide is recommended due to its excellent thermal shock resistance and high thermal conductivity.

- For Uniform Product Quality: Again, silicon carbide stands out as it ensures uniform heat distribution, crucial for achieving consistent product quality.

- For Cost-Sensitive Operations: Alumina offers a balanced performance at a lower cost, making it suitable for applications where budget is a primary concern.

- For Fine and Precision Applications: Zirconia’s superior toughness and thermal shock resistance make it ideal for delicate and precise applications.

Conclusion

Understanding the material properties that affect performance during the sintering process helps make informed decisions that optimize both cost and quality. Whether prioritizing cost, durability, or thermal performance, one of these sintering tray materials will meet your needs. Investing in the right material technology not only enhances the efficiency of sintering operations but also improves the quality and consistency of the final products.

Leave a Reply