Addressing the Challenges in MLCC Sintering: Insights for Advanced Manufacturing

The manufacturing of Multi-Layer Ceramic Capacitors (MLCCs) is a cornerstone of modern electronics, providing essential components used in a myriad of devices from smartphones to automotive electronics. Central to the MLCC manufacturing process is sintering, a critical step that involves firing ceramic layers and internal electrodes to create a robust and functional capacitor. Despite its critical role, MLCC sintering presents several challenges that can impact the efficiency of production and the quality of the final product. This professional blog explores these challenges and offers insights into potential strategies for overcoming them.

Challenge 1: Shrinkage Control and Layer Alignment

One of the foremost challenges in MLCC sintering is controlling the shrinkage of ceramic materials to ensure precise layer alignment and uniformity. Shrinkage is a natural occurrence in the sintering process but can lead to misalignments that compromise the electrical performance of the capacitors.

Strategies for Overcoming: Implementing advanced monitoring and control systems to precisely manage the temperature and atmosphere within the kiln can significantly improve shrinkage uniformity. Additionally, the use of materials and processing techniques that offer reduced and more predictable shrinkage rates can help maintain layer alignment.

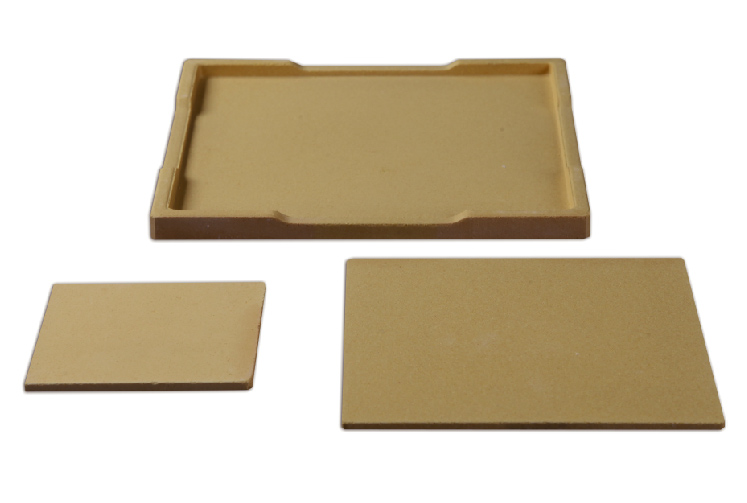

Challenges in MLCC Sintering

Challenge 2: Electrode Material Interaction

During the sintering process, the interaction between ceramic materials and internal electrode materials (typically nickel or palladium-silver for MLCCs) is a critical concern. These interactions can affect the sintering behavior and the final properties of the MLCC, such as its capacitance and reliability.

Strategies for Overcoming: Careful selection of electrode materials that are compatible with the ceramic dielectric materials is crucial. Moreover, optimizing the sintering profile to accommodate the specific characteristics of the electrode materials can minimize adverse interactions and enhance the performance of the MLCC.

Challenges in MLCC Sintering

Challenge 3: Sintering Atmosphere Control

The atmosphere within the sintering kiln must be precisely controlled to prevent oxidation or reduction reactions that could degrade the MLCC’s performance. The choice of atmosphere is particularly critical for capacitors with base metal electrodes, which are more susceptible to oxidation than those with noble metal electrodes.

Strategies for Overcoming: Utilizing advanced kiln technologies with tight atmosphere control capabilities is essential. Implementing an inert or reducing atmosphere, tailored to the specific materials being sintered, can prevent undesirable chemical reactions during the sintering process.

Challenge 4: Minimization of Defects

Defects such as pores, cracks, and delaminations can occur during the sintering process, affecting the MLCC’s structural integrity and electrical properties. These defects are often the result of non-optimal sintering conditions or material impurities.

Strategies for Overcoming: Enhancing the purity of raw materials and employing rigorous quality control measures throughout the manufacturing process can reduce the occurrence of defects. Additionally, optimizing the sintering profile to match the thermal behavior of the materials can help minimize stress and prevent defect formation.

Challenges in MLCC Sintering

Challenge 5: Scalability and Reproducibility

Scaling the sintering process from development to full-scale production while ensuring consistency and reproducibility is a significant challenge. Differences in kiln loading, thermal gradients, and atmosphere uniformity can lead to variability in the sintering outcomes across different production runs.

Strategies for Overcoming: Standardizing processes and employing scalable kiln designs can aid in achieving consistent sintering results. Continuous monitoring and adjustment of process parameters, based on real-time feedback, can further ensure reproducibility at scale.

Conclusion

The sintering process in MLCC manufacturing poses multiple challenges that require careful consideration and innovative solutions. By addressing issues related to shrinkage, electrode material interaction, sintering atmosphere, defect minimization, and scalability, manufacturers can enhance the efficiency and quality of MLCC production. As the demand for MLCCs continues to grow, driven by advancements in electronics, overcoming these sintering challenges will be crucial for meeting the industry’s needs and driving further technological progress.

Leave a Reply