Basic Properties of Corundum-Mullite

In the field of refractory materials, corundum-mullite (3Al₂O₃·2SiO₂) is highly regarded for its superior physical and chemical properties. With the continuous advancement of industrial technology, the demand for high-performance refractory materials has been steadily increasing, and corundum-mullite perfectly meets this need. This article will delve into the basic properties of corundum and mullite, as well as their importance in refractory materials.

Chemical Composition and Crystal Structure

Corundum is aluminum oxide (Al₂O₃), primarily composed of aluminum and oxygen. It exists in several crystal forms, including α-Al₂O₃ and γ-Al₂O₃, with α-Al₂O₃ being the most stable form. The trivalent crystal structure of corundum is dense and stable, allowing it to exhibit excellent strength and toughness in high-temperature environments.

In contrast, mullite is composed of aluminum and silicon oxides, with the chemical formula 3Al₂O₃·2SiO₂. Mullite has a monoclinic crystal structure with a layered configuration, which provides good thermal stability and resistance to thermal shock at high temperatures. This property allows the combination of corundum and mullite in composite materials to maintain excellent performance under extreme conditions, particularly in metallurgy and ceramics.

Physical Properties

Corundum-mullite possesses several important physical properties:

Hardness: Corundum has a Mohs hardness of 9, making it extremely hard and suitable for use as a wear-resistant material. Its high hardness allows corundum-mullite to perform excellently in applications requiring abrasion and impact resistance, such as casting molds and wear liners, effectively reducing wear costs.

Melting Point

The melting point of corundum is approximately 2050°C, while mullite retains good strength above 1700°C. This high melting point characteristic enables corundum-mullite to play a crucial role in high-temperature processes such as steelmaking and ceramic firing. In high-temperature operating environments, this property effectively prevents material deformation and damage.

Thermal Expansion

Corundum-mullite has a relatively low coefficient of thermal expansion, making it resistant to deformation during temperature changes. This effectively avoids thermal shock damage and extends the service life of the material. Especially in environments with frequent temperature fluctuations, the stability of corundum-mullite makes it an ideal choice.

Corrosion Resistance

The excellent chemical stability of corundum-mullite allows it to withstand a variety of acids and alkalis, prolonging its lifespan. This corrosion resistance makes it widely applicable in the chemical and petroleum refining industries, where it continues to perform well in harsh environments.

Thermal Conductivity: Corundum-mullite has moderate thermal conductivity, enabling effective heat transfer in high-temperature conditions, ensuring uniform temperature distribution in equipment and reducing thermal stress.

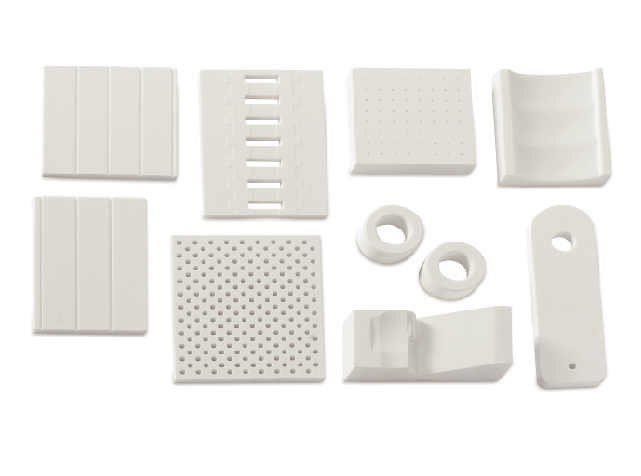

Application Fields

Corundum-mullite is widely used in industries such as metallurgy, ceramics, and glass. Specific applications include:

Metallurgical Industry

In high-temperature furnace linings, furnace refractories, and casting molds, corundum-mullite effectively enhances the durability and safety of equipment. In steelmaking, corundum-mullite can withstand high temperatures while resisting corrosion from furnace materials, ensuring production continuity and stability.

Ceramic Industry

Corundum-mullite is commonly used in the production of refractory bricks and specialty ceramics during ceramic firing. Its high melting point and strength allow it to endure demanding firing conditions, while enhancing the wear and impact resistance of ceramic products.

Glass Manufacturing

In glass production, corundum-mullite is used as high-temperature reaction vessels and furnace linings, ensuring temperature stability during the glass melting process. This not only improves production efficiency but also guarantees the quality of the final product.

Aerospace

In the aerospace sector, corundum-mullite is frequently used to manufacture engine components and thermal insulation materials due to its excellent high-temperature and oxidation resistance, providing safety for aircraft.

Conclusion

Corundum-mullite stands out as a leading refractory material due to its outstanding performance and wide range of applications. Its high hardness, melting point, and excellent corrosion resistance make it indispensable in various high-temperature applications. Understanding the basic properties of corundum-mullite not only aids in selecting suitable refractory materials but also provides valuable information for engineers and technicians in relevant industries.

Leave a Reply