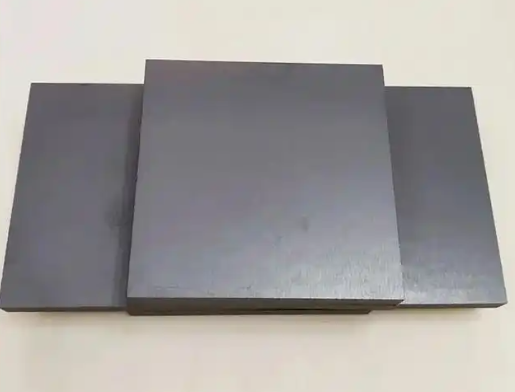

Applications of Recrystallized Silicon Carbide Refractory Materials Across Multiple Industries: Pushing the Limits of High Temperatures and Enhancing Industrial Efficiency

In modern industrial production, high-temperature environments place extremely high demands on the performance of refractory materials. As industrial technologies advance, traditional refractory materials can no longer meet the increasingly complex application requirements. Recrystallized silicon carbide (SiC) stands out as a highly effective refractory material for many high-temperature fields due to its excellent resistance to high temperatures, corrosion, thermal shock, and wear. This blog will focus on the widespread applications of recrystallized silicon carbide in metallurgy, ceramics, glass, and chemical industries, as well as how it helps enhance production efficiency and extend the lifespan of equipment.

-

Applications of Recrystallized Silicon Carbide in the Metallurgical Industry

The metallurgical industry is one of the most prominent fields for the application of recrystallized silicon carbide, especially in processes such as metal smelting, casting, and heat treatment. Metallurgical furnaces, melting furnaces, and high-temperature heating equipment often have to withstand extreme temperatures, high loads, and strong corrosive conditions, while traditional refractory materials are often unable to maintain stability under such harsh conditions.

Melting Furnace Linings: In melting furnaces, recrystallized silicon carbide’s high melting point (approximately 2700°C) allows it to withstand extreme temperatures without melting or softening. This property makes recrystallized silicon carbide an ideal material for furnace linings, significantly extending the furnace’s lifespan and reducing maintenance and replacement frequency.

Thermal Shock Resistance: In the smelting process, temperature changes can be rapid and extreme. Recrystallized silicon carbide exhibits exceptional thermal shock resistance, allowing it to maintain structural stability even under frequent temperature fluctuations. This property is especially valuable in high-temperature furnaces, where it reduces the risk of cracking caused by thermal expansion and contraction, ensuring production stability.

Corrosion Resistance: In the metallurgical industry, molten metals, slag, and gases are often highly corrosive. Due to its resistance to chemical corrosion, recrystallized silicon carbide effectively prevents damage caused by high-temperature chemical reactions, ensuring the longevity of the smelting equipment.

-

Applications of Recrystallized Silicon Carbide in the Ceramics Industry

The ceramic firing process involves high temperatures, often exceeding 1500°C, with complex atmospheres that can damage refractory materials. In this process, recrystallized silicon carbide, with its superior thermal stability and thermal shock resistance, is widely used in various components of ceramic kilns.

Ceramic Kiln Linings: The temperatures in ceramic kilns are typically over 1500°C. Recrystallized silicon carbide’s high melting point and excellent thermal stability allow it to maintain its structure and performance at these high temperatures. As a result, it is widely used in the linings and protective layers of ceramic kilns.

Kiln Furniture and Furnace Components: The high strength and wear resistance of recrystallized silicon carbide make it an ideal material for manufacturing kiln furniture and furnace components. Kiln furniture is often subjected to high temperatures, molten substances, and abrasion, and recrystallized silicon carbide can effectively prevent damage from these factors, extending the life of the equipment.

-

Applications of Recrystallized Silicon Carbide in the Glass Industry

The glass industry is another important sector where recrystallized silicon carbide is used. The temperature in the glass melting process can reach 1400°C to 1600°C, and the molten glass is highly corrosive, making the demand for refractory materials extremely high.

Glass Furnace Linings: Recrystallized silicon carbide’s excellent high-temperature resistance and corrosion resistance allow it to provide superior protection in glass furnaces. Even with prolonged exposure to molten glass, recrystallized silicon carbide remains stable without degradation or damage, significantly extending the lifespan of the furnace.

Insulation and Thermal Protection: Recrystallized silicon carbide has good thermal insulation properties, which help reduce heat loss and improve the energy efficiency of the furnace. In glass production, excellent insulation performance contributes to increased production efficiency and reduced energy consumption.

-

Applications of Recrystallized Silicon Carbide in the Chemical Industry

In the chemical industry, especially in high-temperature chemical reactions and catalyst reactors, recrystallized silicon carbide is widely used due to its excellent high-temperature resistance, corrosion resistance, and thermal shock resistance.

High-Temperature Reactors: In chemical production, many reactors must withstand high temperatures and aggressive corrosive gases and liquids. Recrystallized silicon carbide, as an excellent high-temperature and corrosion-resistant material, is widely used as a lining material in high-temperature reactors, ensuring the longevity and stability of the equipment.

Catalyst Supports and Reactor Linings: The high strength and stability of recrystallized silicon carbide make it an ideal choice for catalyst supports and reactor linings, particularly in environments where both high temperatures and chemical corrosion are a concern.

-

Future Trends in the Development of Recrystallized Silicon Carbide

As industrial technologies continue to evolve, the performance demands on refractory materials are becoming increasingly stringent. In the future, the applications of recrystallized silicon carbide are expected to expand further, especially in emerging fields such as new energy, electronic ceramics, and high-end equipment manufacturing. With the continuous optimization of production processes, the cost of producing recrystallized silicon carbide is expected to decrease, making its application even more widespread.

-

Conclusion

Recrystallized silicon carbide, with its unique high-temperature stability, corrosion resistance, thermal shock resistance, and wear resistance, is being increasingly applied across various industries. Whether in metallurgy, ceramics, glass, or chemical sectors, recrystallized silicon carbide effectively enhances the lifespan of equipment and boosts production efficiency. As technology progresses and demand grows, the future application prospects of recrystallized silicon carbide in high-temperature environments will continue to expand. By choosing the right recrystallized silicon carbide refractory materials, companies can meet the stringent demands of industrial production while achieving long-term economic benefits.

Leave a Reply