Application of Porous Plates in the Aerospace Field: The Perfect Combination of Lightweight and High-Temperature Resistance

The aerospace industry imposes extremely stringent requirements on material performance, particularly in extreme environments characterized by high temperatures, high pressure, and intense vibrations. Stability, lightweight properties, and durability are critical for materials used in such conditions. Porous plates, as a high-performance ceramic material, have gained widespread application in the aerospace field due to their unique porous structure, excellent high-temperature resistance, and lightweight characteristics. This article delves into the specific applications and technical advantages of porous plates in the aerospace industry.

1. Characteristics of Porous Plates and Aerospace Requirements

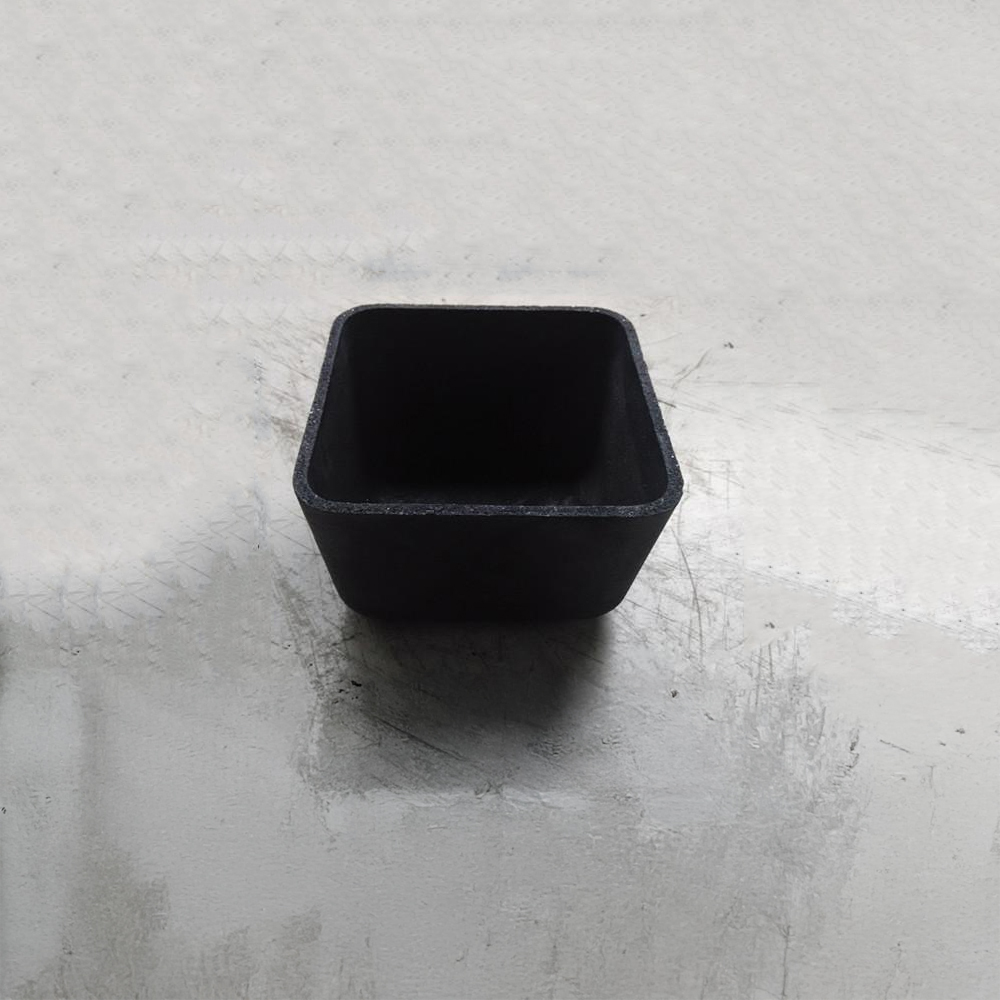

Porous plates are porous structural materials made from ceramic materials through high-temperature co-firing processes. Their main characteristics include:

High Porosity: Porosity can reach 30%-70%, providing low density and excellent thermal insulation properties.

High-Temperature Resistance: Ceramic materials inherently have high melting points and thermal stability, making them suitable for high-temperature environments.

Lightweight: The porous structure significantly reduces material density, meeting the aerospace industry’s demand for lightweight solutions.

Mechanical Strength: Through material and process optimization, porous plates maintain sufficient mechanical strength while being lightweight.

These properties make porous plates an ideal functional material for the aerospace industry, particularly in applications such as engines, thermal protection systems, and structural components.

2. Application of Porous Plates in Aircraft Engines

Aircraft engines are the “heart” of an aircraft, operating at temperatures exceeding 1000°C, which places extremely high demands on the high-temperature resistance and heat dissipation properties of materials. Porous plates are used in engines in the following ways:

Combustor Liners: Porous plates serve as combustor liner materials, effectively insulating against and withstanding the impact of high-temperature gases. Their porous structure also enables film cooling technology to reduce surface temperatures and extend component lifespan.

Turbine Blade Coatings: Porous plates can be used as thermal barrier coatings for turbine blades, reducing the impact of high temperatures on metal substrates and improving blade durability.

Exhaust Nozzle Components: In exhaust nozzles, porous plates are used to create high-temperature-resistant insulation layers, minimizing heat transfer to surrounding structures.

The use of porous plates has significantly enhanced the performance and reliability of aircraft engines while achieving lightweight design goals.

3. Application of Porous Plates in Thermal Protection Systems

In spacecraft, thermal protection systems (TPS) are critical for ensuring safe re-entry into Earth’s atmosphere. Porous plates are used in TPS in the following ways:

Insulation Layers: The high porosity and low thermal conductivity of porous plates make them ideal insulation materials, effectively blocking high-temperature airflow from affecting the spacecraft’s internal structure.

Heat Shields: During atmospheric re-entry, surface temperatures can reach thousands of degrees Celsius. Porous plates serve as heat shields, withstanding extreme temperatures and protecting internal equipment.

Lightweight Design: Compared to traditional metal materials, porous plates have lower density, significantly reducing the weight of thermal protection systems and increasing the spacecraft’s payload capacity.

For example, porous plates have been widely used in the thermal protection systems of U.S. spacecraft, demonstrating remarkable effectiveness.

4. Application of Porous Plates in Aerospace Structural Components

Beyond engines and thermal protection systems, porous plates also play a vital role in aerospace structural components:

Lightweight Supports: Porous plates can be used to manufacture aircraft supports and structural frames, ensuring strength while reducing weight.

Sensor Housings: Sensors in aerospace vehicles must operate reliably in extreme environments. Porous plates, as sensor housing materials, provide excellent thermal insulation and protection.

Radome: The high-frequency wave-transparent properties of porous plates make them ideal for radomes, protecting antennas from high temperatures and aerodynamic forces.

5. Technical Challenges and Future Development Directions

Despite their significant potential in the aerospace field, the application of porous plates faces several technical challenges:

Process Complexity: The manufacturing process for porous plates is complex, particularly in controlling porosity precisely and addressing deformation during sintering.

Cost Issues: High-performance ceramic materials and complex production processes result in high costs, limiting large-scale applications.

Performance Optimization: Balancing high porosity with improved mechanical strength and thermal stability remains a key research focus.

In the future, with the development of new materials and processes, the application of porous plates in the aerospace field will expand further. For instance, the introduction of nano-ceramic materials and 3D printing technology is expected to enhance the performance of porous plates while reducing costs.

Conclusion

Porous plates, with their unique porous structure, excellent high-temperature resistance, and lightweight properties, demonstrate immense potential in the aerospace field. From aircraft engines to thermal protection systems and structural components, porous plates are playing a crucial role in advancing aerospace technology. Despite facing technical challenges, ongoing advancements in material science and manufacturing processes will undoubtedly enable porous plates to play an even more significant role in the future of aerospace.

Leave a Reply