21,August,2024

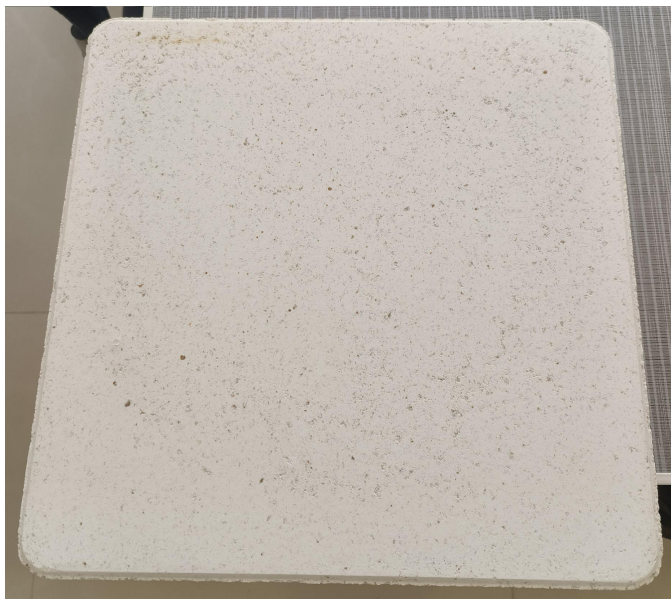

Andalusite Setter Plates: Unmatched Thermal Shock Resistance for High-Temperature Industries

The Importance of Thermal Shock Resistance

Applications in Environments with Rapid Temperature Changes

- Ceramics Industry: Andalusite setter plates frequently endure drastic temperature fluctuations in ceramic kilns, especially during firing and cooling processes. These plates must remain intact under rapid heating and cooling to avoid cracks and damage, ensuring the quality of ceramic products.

- Metallurgical Industry: Lining materials in metallurgical furnaces are subjected to impacts from high-temperature molten metal and rapid temperature changes from cooling water. The thermal shock resistance of andalusite setter plate is crucial for preventing lining fractures and extending furnace life.

Impact on Plate Performance and Longevity:

- Resisting Thermal Stress: In high-temperature environments, materials experience stress due to temperature changes. If the thermal shock resistance is inadequate, plates may develop cracks, spall, or even break, affecting the stability of the production process.

- Extending Service Life: Plates with excellent thermal shock resistance can maintain structural integrity under repeated thermal shocks, extending their service life, reducing replacement frequency, and thereby lowering production costs.

Practical Verification: Exploring the Thermal Shock Resistance of Andalusite Setter Plates

Industrial Application Testing:

- Test Objective: Validate the performance of andalusite setter plate under high temperatures and rapid temperature changes through tests in actual production environments.

- Test Materials: Select representative samples of andalusite setter plates to ensure broad applicability of the test results.

- Test Method:

- Sample Preparation: Cut samples to standard dimensions (e.g., 20x20x200 mm) and clean the surface to remove impurities.

- Application Environment: Apply samples in real production environments, such as ceramic kilns and metallurgical furnaces, simulating high-temperature and rapid cooling conditions.

- Monitoring and Recording: Regularly monitor physical changes in the samples during the production process, such as crack formation, weight changes, and dimensional changes. Record all data throughout the use cycle to ensure accuracy and completeness.

Laboratory Simulation Testing:

- Test Objective: Simulate thermal shock conditions in a controlled environment to thoroughly evaluate the thermal shock resistance of andalusite setter plates.

- Test Materials: Use the same samples from the industrial application test to ensure data consistency.

- Test Method:

- Sample Preparation: Ensure consistent sample size and surface conditions.

- Test Equipment: Use laboratory high-temperature furnaces and cooling equipment to simulate thermal shock processes experienced in real production environments.

- Process and Recording: Heat the samples in a furnace to 1500°C, maintain for a set period, then quickly remove and immerse in a cooling medium. Repeat this process, recording crack development, weight changes, and mechanical performance changes.

Results Analysis: Demonstrating the Superior Thermal Shock Resistance of Andalusite Setter Plates

Test Data:

- Industrial Application Test Results: In real production environments, andalusite setter plate samples exhibited extremely high thermal shock resistance. After multiple production cycles, only minor cracks appeared on the surface, with weight changes less than 0.5% and negligible dimensional changes.

- Laboratory Simulation Test Results: Under prolonged, high-frequency thermal shocks, andalusite setter plate samples maintained excellent mechanical performance, with slow crack propagation and overall structural integrity.

Application Value:

- Excellent Thermal Shock Resistance: Test results show that andalusite setter plates perform exceptionally well in environments with rapid temperature changes, resisting stress caused by high temperatures and rapid cooling, ensuring reliability in high-temperature industries.

- Extended Service Life: Outstanding thermal shock resistance significantly extends the service life of andalusite setter plates, reducing replacement frequency, lowering maintenance costs, and improving production efficiency.

- Enhanced Production Stability: Andalusite setter plates provide stable performance in high-temperature industries, reducing downtime caused by material failure, and ensuring continuous production.

Improvement Suggestions:

- Optimize Material Composition: Further optimize the material composition of andalusite setter plates, such as adjusting the ratio of aluminosilicate and adding reinforcing fibers or other heat-resistant materials to enhance thermal shock resistance.

- Improve Manufacturing Processes: Refine sintering and cooling processes, control grain size and distribution, and reduce internal stress concentration in materials to enhance the thermal shock resistance of the plates.

- Surface Treatment Technologies: Apply advanced surface treatment technologies, such as coatings and impregnations, to enhance the heat resistance and crack resistance of the plates’ surfaces.

Conclusion:

- Through testing the thermal shock resistance of andalusite setter plates in real production environments and laboratory simulations, it is confirmed that they exhibit excellent thermal shock resistance in conditions with rapid temperature changes. These characteristics make andalusite setter plates indispensable materials in the ceramics and metallurgical industries.

- It is recommended to further optimize process parameters and material composition in practical production applications to ensure the quality and performance of Andalusite kiln furniture, meeting the stringent requirements of refractory materials in high-temperature industries.

Andalusite kiln furniture has excellent thermal shock resistance, making it a key material for high-temperature industries. Through in-depth practical verification, we have revealed its stable performance in environments with rapid temperature changes, providing a scientific basis for its optimization in practical applications. Andalusite kiln furniture is not only a strong support for the ceramics and metallurgy industries but also an important direction for the future development of high-temperature materials.

样品制备:将样品切割成标准尺寸(例如20x20x200毫米)并清洁表面以去除杂质。

![Andalusite Pusher Tray [MM-LY-HZ75]](https://moatcity.com/wp-content/uploads/2024/10/222-2.jpg)

Leave a Reply