Analysis of Refractory Properties of Corundum Mullite

Alumina-mullite (3Al₂O₃·2SiO₂) is a crucial component in refractory materials, widely used in industrial applications due to its excellent refractory properties. This article explores the key refractory characteristics of alumina-mullite, including its refractoriness, thermal stability, thermal shock resistance, and thermal conductivity, and provides experimental data and practical applications to give readers a comprehensive understanding.

1. Refractoriness

Refractoriness is the primary indicator of a refractory material’s stability under high-temperature conditions. The refractoriness of alumina-mullite is typically above 1700°C, offering excellent performance in high-temperature environments. For instance, in high-temperature metallurgical processes, alumina-mullite significantly reduces the risk of melting compared to traditional refractory bricks, effectively extending the service life of furnace linings. Its high refractoriness enables the material to resist corrosion from molten metals or glass, ensuring the safety and efficiency of the production process.

2. Thermal Stability

Thermal stability refers to a material’s ability to maintain its properties under high temperatures. Alumina-mullite exhibits outstanding thermal stability, retaining its physical and chemical properties after multiple high-temperature cycles. This characteristic allows it to withstand extreme temperature fluctuations, particularly in metallurgy and ceramics, effectively resisting thermal shock. For example, in ceramic kilns, alumina-mullite can endure rapid heating and cooling without noticeable deformation or cracking, thus ensuring product quality.

3. Thermal Shock Resistance

Thermal shock resistance refers to a material’s ability to resist cracking and damage caused by rapid temperature changes. Alumina-mullite, due to its excellent crystal structure, exhibits superior thermal shock resistance compared to many other refractory materials. This structure effectively dissipates thermal stresses, reducing the likelihood of crack formation. For instance, in glass furnaces, using alumina-mullite as an inner lining significantly lowers the risk of thermal shock damage, thereby improving the overall efficiency of the equipment.

4. Thermal Conductivity

Thermal conductivity is an indicator of a material’s ability to conduct heat, directly impacting energy efficiency. Alumina-mullite has moderate thermal conductivity, allowing for effective thermal insulation while also providing rapid heat dissipation when needed. This property makes it an ideal choice for furnace linings in industrial applications. For example, in casting processes, alumina-mullite can quickly dissipate heat, preventing excessive temperatures from negatively affecting casting quality. Furthermore, its moderate thermal conductivity reduces heat loss within the furnace, thereby improving overall energy efficiency.

5. Experimental Data and Case Studies

Extensive experimental studies have shown that alumina-mullite outperforms other refractory materials under extreme conditions. One study demonstrated that in high-temperature furnace tests, the service life of alumina-mullite was extended by over 30% compared to traditional refractory bricks. These findings highlight not only the superiority of alumina-mullite in high-temperature environments but also its importance in reducing maintenance costs and improving production efficiency. In the casting industry, using alumina-mullite as mold material not only enhances the durability of molds but also reduces the incidence of casting defects.

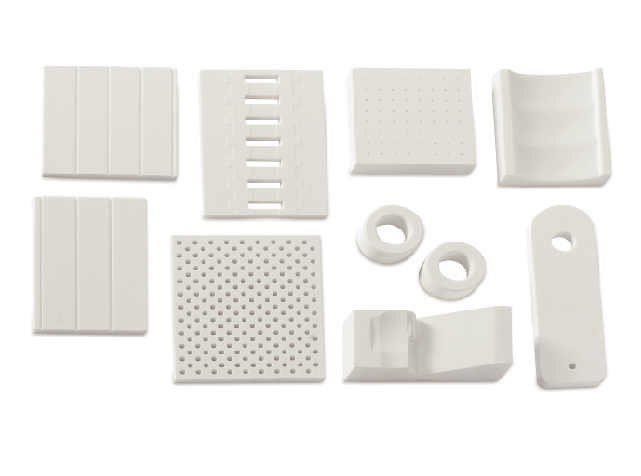

6. Application Areas

The exceptional performance of alumina-mullite has led to its widespread use across multiple industrial sectors. It is used in metallurgy, ceramics, glass, and petrochemical industries as furnace linings, molds, and insulation materials. Specifically, in the aluminum and other metal smelting processes, the high refractoriness and thermal shock resistance of alumina-mullite ensure the safe and stable operation of furnaces under extreme conditions. In ceramic manufacturing, its thermal stability guarantees the consistency of products during the firing process.

Conclusion

In summary, alumina-mullite offers unparalleled refractory performance advantages, with its refractoriness, thermal stability, thermal shock resistance, and thermal conductivity making it an ideal choice for high-temperature industrial applications. Understanding these performance characteristics can help engineers and materials scientists select the appropriate refractory materials and achieve higher efficiency and safety in practical applications. With ongoing technological advancements and the development of new materials, the applications of alumina-mullite are expected to expand further, driving progress in the field of refractory materials. By gaining a deeper understanding of alumina-mullite’s properties, industries can better utilize this critical material to gain a competitive advantage in an increasingly competitive market.

Leave a Reply