99% Alumina Ceramics Machining Challenges: Insights and Strategies

1. Introduction to Alumina Ceramic:

Alumina Ceramic, commonly known as aluminum oxide (Al2O3), is a standout material in the ceramic industry. Its prominence is attributed to:

- Exceptional Hardness: One of the hardest ceramic materials available.

- Electrical Insulation: Ideal for electronic substrates due to its insulating properties.

- High-Temperature Resistance: Can withstand extreme temperatures, making it suitable for various industrial applications.

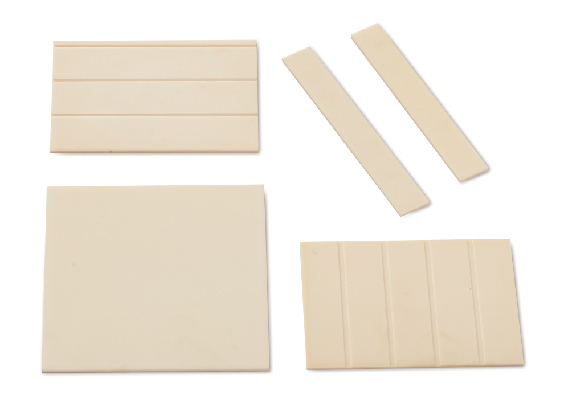

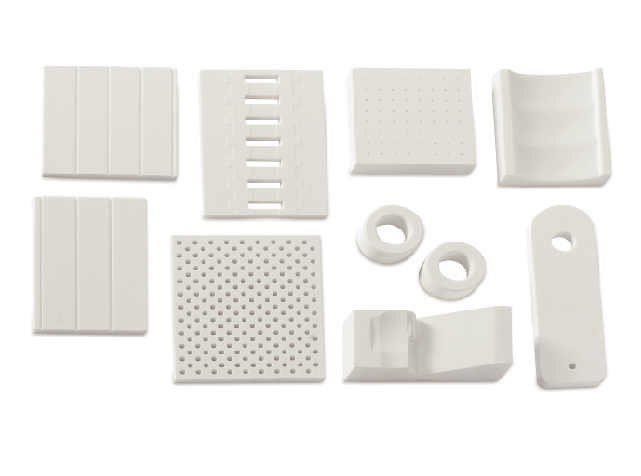

2. Key Applications:

Alumina Ceramic’s unique properties have led to its widespread use in:

- Electronic Substrates: Due to its electrical insulation capabilities.

- Wear-Resistant Components: Its hardness ensures durability in machinery parts.

- Advanced Bio-Ceramic Applications: Safe for medical and biological uses.

3. Deep Dive into the Complexities of 99% Alumina Ceramic Processing:

Alumina Ceramic is a cornerstone in modern engineering, known for its exceptional hardness and brittleness. Its distinct properties and composition have made it a vital component in various industries. However, crafting especially those with 99% purity, presents challenges.

- Processing Hardness: The bonds in α-Al2O3, be they covalent or ionic, lead to high atomic bonding energy. This results in Alumina Ceramic’s brittleness, causing minimal plastic deformation and a tendency for cracking.

- Processing Brittleness: Alumina Ceramic products often have low fracture toughness. External stresses can lead to micro-cracks on the surface. During machining, chipping or small notches can form. The intensity of these issues correlates with the tensile stress during machining.

4. Strategies to Overcome Challenges in 99% Alumina Ceramic Processing:

Despite these challenges, the abundant resources of alumina combined with modern, advanced techniques offer promising solutions for processing alumina ceramics. Here are some considerations for improving the processing of alumina ceramics:

- Material Selection Precision: Choosing the right α-Al2O3 form is crucial. The specific composition can impact the product’s hardness and brittleness.

- Optimization of the Cutting Process: A refined cutting technique can reduce stress and prevent chipping. The right cutting tools and coolants can transform the machining process.

- Proactive Stress Management: Managing tensile stress during processing is vital. Adjusting the speed, temperature, or pressure ensures product integrity.

5. Contact Details:

Leading the Alumina Ceramic processing domain, we champion research and innovation. We’re committed to refining our processes and delivering top-tier Alumina Ceramic products.

For more on our Alumina Ceramic processing strategies or inquiries, please contact us. Our expert team is here to help.

Email: rongqi.chen@moatcity.com

Web: www.moatcity.com

WhatsApp: +447983626714

We’re eager to assist with your Alumina Ceramic needs.

Leave a Reply