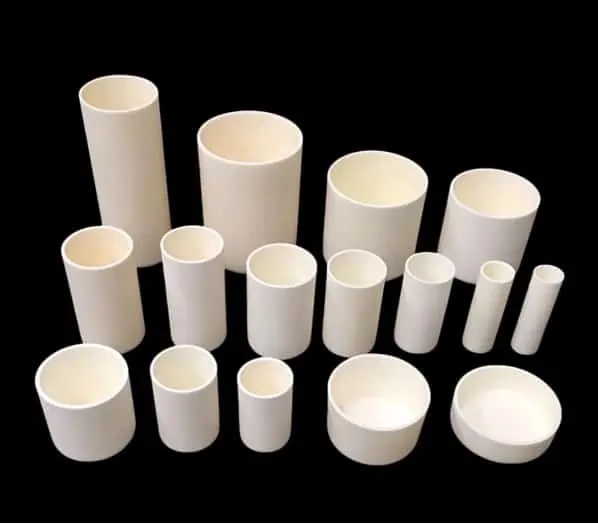

99% Alumina Crucibles: The Ideal Choice for High-Temperature Sintering

Alumina (Al₂O₃) is a highly favored material in modern material science and industrial production due to its excellent properties and broad range of applications. The 99% alumina crucible, with its high purity and superior physical and chemical properties, has become an indispensable tool in high-temperature sintering processes.

Production Process

The production of 99% alumina crucibles involves several key steps to ensure their high purity and excellent performance:

- Raw Material Selection: High-purity alumina powder is selected as the raw material to ensure the purity and performance of the final product.

- Powder Preparation: The alumina powder is finely ground to ensure uniform particle size, improving the sintering density and mechanical properties of the final product.

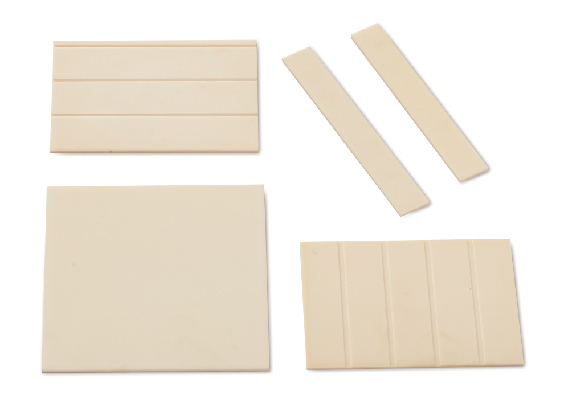

- Shaping: The alumina powder is shaped into a green body using dry pressing, isostatic pressing, or injection molding. The pressing pressure and mold design must be strictly controlled to ensure dimensional accuracy and uniform density of the green body.

- Sintering: The green body is sintered in a high-temperature furnace, typically within a temperature range of 1600°C to 1800°C. This process promotes diffusion and recrystallization of the alumina particles, resulting in a dense microstructure.

- Post-Processing: After sintering, the crucible undergoes necessary post-processing steps such as grinding and polishing to ensure surface smoothness and dimensional accuracy.

Advantages of 99% Alumina Crucibles

99% alumina crucibles offer several advantages:

- High Temperature Stability: These crucibles remain stable in high-temperature environments, making them suitable for sintering processes up to 1700°C.

- High Mechanical Strength: The dense microstructure and high-purity material provide excellent bending strength and hardness.

- Corrosion Resistance: They show good resistance to most acids, alkalis, and solvents, making them suitable for various chemical environments.

- Excellent Thermal Conductivity: This helps evenly distribute heat, preventing localized overheating and stress concentration.

Applications of 99% Alumina Crucibles

Due to their excellent properties, 99% alumina crucibles are widely used in the following fields:

- Materials Science: For research and development of high-temperature and ultra-high-temperature materials.

- Electronics Industry: As a sintering base for semiconductor materials, electronic components, and sensors.

- Chemical Industry: Used in the preparation of high-temperature chemical reactors and catalyst supports.

- Optical Devices: In the manufacturing processes of high-temperature optical materials and optical fibers.

Powders Suitable for Sintering in 99% Alumina Crucibles

99% alumina crucibles are suitable for sintering a variety of high-temperature powder materials, including but not limited to:

- Oxide Ceramics: Such as alumina (Al₂O₃), zirconia (ZrO₂), yttria (Y₂O₃).

- Carbide Ceramics: Such as silicon carbide (SiC), boron carbide (B₄C).

- Nitride Ceramics: Such as silicon nitride (Si₃N₄).

- Composite Materials: Such as oxide-carbide composites, metal matrix composites.

Temperature Suitability

99% alumina crucibles are suitable for a variety of high-temperature environments, typically with the following temperature ranges:

- General Applications: From 0°C to 1700°C.

- Short-term Applications: Can withstand up to 1800°C for short-term high-temperature treatment.

Conclusion

99% alumina crucibles, with their excellent high-temperature performance and wide applicability, have become an indispensable tool in high-temperature sintering processes. Whether in material research or industrial production, they demonstrate outstanding performance and reliability, providing a solid foundation for the development and application of high-temperature materials.

Leave a Reply