The Basics of Metal Injection Molding (MIM) and the Role of Ceramic Furnace Setters

Metal Injection Molding (MIM) represents a remarkable fusion of the plastic injection molding process with powdered metallurgy. This innovative manufacturing technique allows for the production of complex metal parts with high precision and excellent material properties, akin to those achieved through traditional metal forming methods. The essence of MIM lies in its ability to produce large volumes of parts that require minimal finishing processes, thereby economizing both time and resources. In this blog, we delve into the foundational aspects of MIM and spotlight the crucial role played by ceramic furnace setters, with a focus on materials like corundum mullite, 99% alumina, and zirconia.

Understanding Metal Injection Molding (MIM)

Metal Injection Molding is a multi-step process that begins with the mixing of fine metal powders with a binder (polymer or wax-based) to form a feedstock. This feedstock is then heated and injected into a mold cavity, similar to the plastic injection molding process. After molding, the part undergoes a debinding process to remove the majority of the binder, leaving behind a porous metal structure. The final step, sintering, involves heating the part to a temperature below the melting point of the metal, causing the particles to fuse together and densify into a solid metal component.

The Significance of Sintering

Sintering is a critical phase in MIM, dictating the mechanical properties, density, and strength of the final product. It’s during this high-temperature process that the role of ceramic furnace setters becomes paramount.

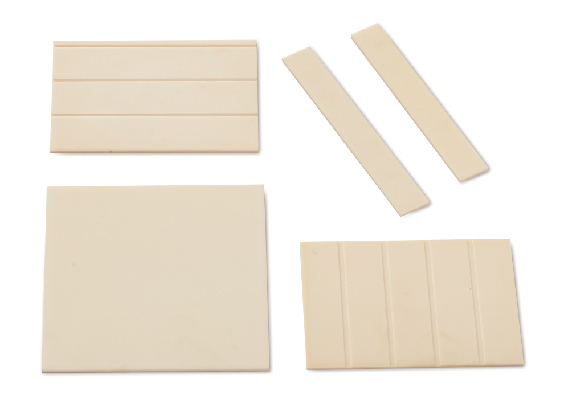

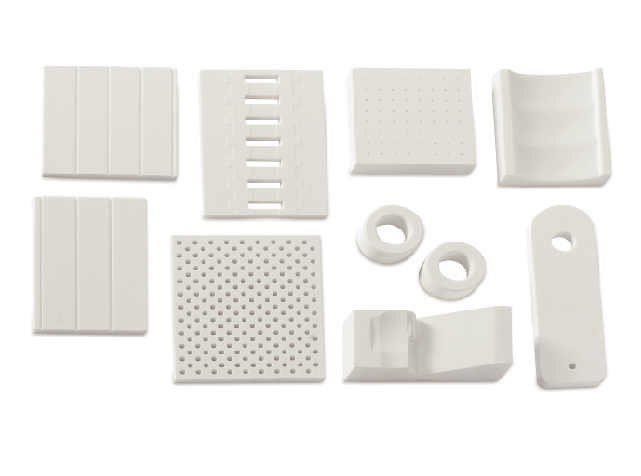

The Role of Ceramic Furnace Setters

Ceramic furnace setters are specialized tools used to support and protect the metal parts during the sintering process. These setters are made from high-purity ceramics such as corundum mullite, 99% alumina, and zirconia, chosen for their exceptional thermal stability, resistance to thermal shock, and minimal interaction with the parts being sintered. Let’s explore the advantages of each material:

Corundum Mullite

Corundum mullite combines the high thermal stability of alumina with the excellent thermal shock resistance of mullite, making it an ideal choice for supporting parts through the thermal cycling of the sintering process. This material is particularly beneficial for components that require precise dimensional control.

99% Alumina

With its outstanding high-temperature performance and chemical inertness, 99% alumina setters provide an excellent surface for parts, minimizing the risk of contamination. Its robustness makes it suitable for long-term use in harsh sintering environments.

Zirconia

Zirconia is renowned for its high strength and toughness at elevated temperatures. Its thermal insulation properties are advantageous for energy-efficient sintering processes, and its resistance to chemical attack ensures the purity of the sintered parts.

Why Ceramic Setters Matter

The choice of ceramic material for furnace setters can significantly influence the quality and properties of the MIM parts. These ceramics must withstand not only the high temperatures involved in sintering but also the mechanical stresses and potential chemical interactions with the metal powders. The correct selection helps in achieving uniform heat distribution, preventing part deformation, and ensuring the dimensional accuracy of the final products.

Conclusion

Metal Injection Molding is a sophisticated process that benefits greatly from the use of ceramic furnace setters. The materials discussed — corundum mullite, 99% alumina, and zirconia — each bring unique properties to the table, ensuring the production of high-quality metal parts. As MIM continues to evolve and find applications across industries, the role of these ceramic components will undoubtedly remain indispensable, marking a fusion of materials science and manufacturing excellence.

Leave a Reply