The Role of Refractory Kiln Furniture in the Formation of Thermocouples Tubes

1. Introduction to Refractory Kiln Furniture and Thermocouples Tubes:

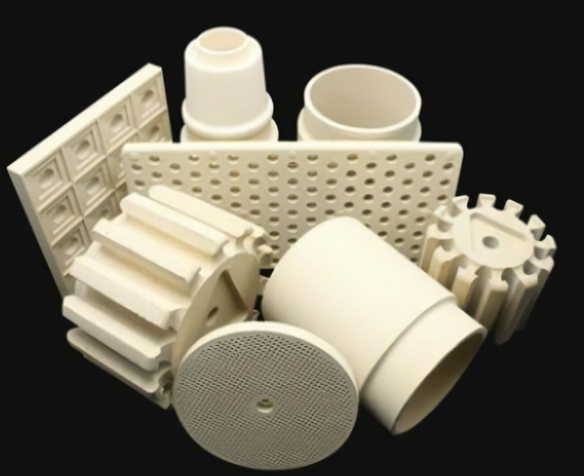

Refractory kiln furniture, a specialized category of high-performance ceramics, plays a pivotal role in the sintering process, a critical step in the production of thermocouples tubes. This article aims to provide an in-depth understanding of how Moat City Limited’s refractory kiln furniture enhances the quality and performance of thermocouples tubes, which are essential for accurate temperature monitoring in various industrial settings.

2. The Importance of Sintering in Thermocouples Production:

Sintering is a key process in the production of thermocouples tubes, where raw materials are transformed into a durable, finished product. The quality of sintering directly impacts the performance and longevity of thermocouples. However, achieving optimal sintering conditions requires specialized equipment—this is where Moat City Limited’s refractory kiln furniture comes into play.

a. Challenges in Sintering:

- Temperature Uniformity: Achieving uniform temperature is crucial for consistent sintering, yet difficult to maintain.

- Chemical Reactions: The sintering process can be affected by unwanted chemical reactions between the material and the surrounding environment.

b. The Need for Specialized Equipment:

- Thermal Stability: Equipment must be thermally stable to maintain the required sintering temperature.

- Chemical Inertness: To prevent undesirable chemical reactions, the equipment must be made of chemically inert materials.

Given these challenges, it’s clear that specialized equipment is essential for the successful sintering of thermocouples tubes. Moat City Limited’s refractory kiln furniture is designed to meet these specific needs.

3. How Moat City Limited’s Refractory Kiln Furniture Enhances Sintering:

Moat City Limited’s refractory kiln furniture is engineered to provide optimal conditions for the sintering process, thereby enhancing the quality of thermocouples tubes. Here’s how:

a. Thermal Stability:

- Uniform Heat Distribution: Our kiln furniture is designed for uniform heat distribution, ensuring consistent sintering across the entire batch of thermocouples tubes.

- High-Temperature Resistance: Made from materials that can withstand extreme temperatures, our kiln furniture maintains its structural integrity throughout the sintering process.

b. Chemical Inertness:

- Material Compatibility: Our refractory materials are chemically inert, preventing any undesirable reactions during sintering that could compromise the quality of the thermocouples tubes.

- Corrosion Resistance: The chemical stability of our kiln furniture also means it is highly resistant to corrosion, extending its lifespan and reducing long-term costs.

c. Customization:

- Specific Needs: We offer customized solutions tailored to the specific sintering requirements of different industries, ensuring optimal performance.

- Expert Consultation: Our team of experts can guide you in selecting the most suitable kiln furniture for your sintering process.

By addressing these critical factors, Moat City Limited’s refractory kiln furniture ensures a superior sintering process, leading to high-quality thermocouples tubes that meet industry standards.

4. Case Studies:

To further illustrate the impact of our refractory kiln furniture on the sintering process, let’s look at some real-world case studies:

a. Aerospace Industry:

- Problem: An aerospace manufacturer customer was facing inconsistencies in the sintering process, affecting the reliability of their thermocouples.

- Solution: Moat City Limited provided customized kiln furniture that ensured uniform heat distribution, resulting in consistent and reliable thermocouples.

b. Automotive Industry:

- Problem: Our leading automotive client was experiencing frequent equipment failures due to the corrosive environment in their sintering kilns.

- Solution: Our corrosion-resistant kiln furniture significantly reduced equipment downtime, leading to a more efficient sintering process and higher-quality thermocouples.

These case studies underscore the tangible benefits of using Moat City Limited’s refractory kiln furniture in the sintering process, solidifying its essential role in producing superior thermocouples tubes.

5. Material Considerations for Moat City Limited’s Refractory Kiln Furniture:

When selecting kiln furniture for sintering thermocouples tubes, several material properties must be considered:

a. Thermal Conductivity:

- Low Thermal Conductivity: Ideal for applications requiring thermal insulation, ensuring a stable sintering environment.

- High Thermal Conductivity: Necessary for applications requiring rapid heat transfer, ensuring uniform sintering.

b. Mechanical Strength:

- Compressive Strength: Important for heavy-load applications, ensuring the kiln furniture maintains its shape and integrity.

- Tensile Strength: Crucial for applications involving pulling or stretching forces, ensuring the kiln furniture doesn’t crack or deform.

c. Cost-Effectiveness:

- Initial Cost: While some materials may be expensive upfront, they can offer long-term savings by reducing maintenance and replacement costs.

- Lifecycle Cost: Consider the total cost, including maintenance and potential downtime, when choosing kiln furniture material.

Moat City Limited offers a range of materials, each with its unique set of properties to meet the specific needs of your sintering process.

6. Future Trends and Innovations:

The field of refractory kiln furniture is continuously evolving, with research focused on developing materials with higher performance characteristics. Innovations include:

a. Nanotechnology:

- Nano-coatings: Enhance surface properties, offering improved resistance to wear and corrosion.

- Nano-composites: Offer enhanced mechanical and thermal properties, opening up new application possibilities.

b. Environmental Sustainability:

- Recyclability: Focus on materials that are easily recyclable to minimize environmental impact.

- Energy Efficiency: Materials offering better energy efficiency can significantly reduce operational costs.

Moat City Limited is committed to staying at the forefront of these innovations, continually updating our product offerings to include the latest advancements in kiln furniture technology.

7. Conclusion:

Moat City Limited’s refractory kiln furniture plays a critical role in the sintering process, directly contributing to the production of high-quality thermocouples tubes. With a range of materials and ongoing innovations, we offer customized solutions that meet the specific needs of various industries, ensuring optimal performance and cost-effectiveness.

8. Contact Details:

For more information on how our refractory kiln furniture can benefit your sintering process, please contact us.

Email: rongqi.chen@moatcity.com

Web: www.moatcity.com

WhatsApp: +447983626714

We’re eager to assist with your refractory kiln furniture needs.

Leave a Reply