Future Prospects of Aluminum Nitride in High-Temperature Electrical Insulation

In the rapidly evolving landscape of power electronics, renewable energy, aerospace, and semiconductor manufacturing, the demand for materials that can withstand high temperatures while providing reliable electrical insulation is at an all-time high. Among the few materials that can meet these stringent dual demands, aluminum nitride (AlN) has emerged as a top-tier candidate.

With its unique combination of exceptional thermal conductivity, electrical insulating properties, and chemical and thermal stability, aluminum nitride is increasingly being adopted or researched as a core material in high-temperature electrical insulation systems. This article explores the current and future applications of AlN in this space and what makes it such a strong contender.

- The Challenge of High-Temperature Electrical Insulation

Modern industries are pushing components to operate in more extreme environments:

Electric vehicle inverters generate substantial heat.

Power electronics operate at higher voltages and frequencies.

Aerospace engines and fusion energy systems subject materials to thermal, mechanical, and electromagnetic stress simultaneously.

Traditional insulating materials like alumina, mica, and polymers suffer performance degradation or failure beyond ~500–600 °C. This is where aluminum nitride steps in with a unique property set:

| Property | Aluminum Nitride (AlN) |

| Thermal Conductivity | 140–285 W/m·K |

| Electrical Resistivity | >10¹³ Ω·cm |

| Maximum Operating Temp | ~1800 °C |

| Dielectric Strength | 8–12 kV/mm |

| Coefficient of Thermal Expansion (CTE) | ~4.5×10⁻⁶ /K |

This rare balance between heat dissipation and dielectric insulation makes AlN highly attractive for advanced insulation systems.

- Key Application Areas

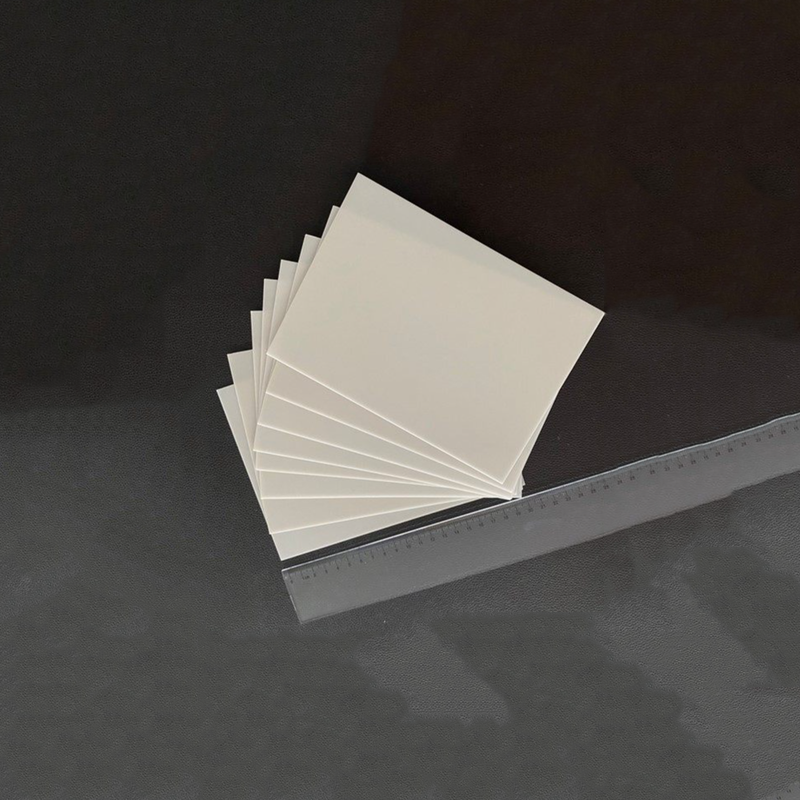

- Power Electronics Substrates

In insulated metal substrates (IMS) and direct bond copper (DBC) systems, thermal management and electrical isolation are critical. AlN ceramics are increasingly replacing alumina and beryllia in power semiconductor packages due to:

High thermal conductivity, which efficiently removes heat from high-power chips.

Electrical insulation, allowing devices to operate at high voltage without short-circuiting.

Thermal expansion matching, reducing mechanical stress when paired with silicon or GaN devices.

Use Cases:

IGBT and MOSFET modules

Automotive traction inverters

RF and microwave packaging

- High-Temperature Sensor and Coil Insulation

Sensors and electromagnet coils used in jet engines, turbine generators, or plasma systems require insulating materials that survive hundreds or even thousands of thermal cycles. AlN components (coatings or molded parts) provide:

Electrical insulation up to 1000+ °C

Resistance to oxidation and thermal shock

Mechanical robustness under vibrational load

These properties make AlN suitable for embedded sensors, magnetic cores, and thermal isolators in demanding environments.

- Dielectric Layers in Harsh Environment Electronics

AlN is compatible with various deposition techniques, including chemical vapor deposition (CVD) and physical vapor deposition (PVD), making it ideal for thin-film insulation layers in microelectronic applications. Benefits include:

High breakdown voltage

Chemical inertness (especially in vacuum or reducing environments)

Excellent adhesion to silicon, sapphire, or metal substrates

As electronics increasingly move into extreme-temperature environments (e.g., space, deep drilling, nuclear systems), AlN’s role in dielectric layering is likely to expand significantly.

- High-Voltage Bushings and Feedthroughs

In systems where voltage isolation is required at high temperatures—such as fusion reactors, plasma chambers, or vacuum furnaces—AlN serves as an ideal material for feedthrough insulators, ceramic seals, and electrical bushings. Compared to traditional insulators like alumina, AlN offers:

Better thermal dissipation (reducing arc risk)

Enhanced mechanical strength at elevated temperatures

Longer life span in high-frequency AC applications

- Comparison with Other High-Temperature Insulators

| Material | Max Temp (°C) | Thermal Conductivity (W/m·K) | Electrical Resistivity (Ω·cm) | Notes |

| Aluminum Nitride | ~1800 | 140–285 | >10¹³ | Excellent dual performance |

| Alumina | ~1700 | ~30 | >10¹⁴ | Lower thermal performance |

| Zirconia | ~2400 | ~2–3 | >10¹³ | Poor thermal conductivity |

| Beryllia | ~1550 | ~250 | >10¹³ | Toxic, handling concerns |

| Silicon Nitride | ~1600 | ~30 | >10⁸ | Not a great insulator at high temp |

Conclusion: AlN is one of the very few materials that maintain both high thermal conductivity and excellent electrical insulation well above 1000 °C.

- Future Outlook and Innovation Areas

As system temperatures and voltage ratings rise, the materials used for insulation must also evolve. Some ongoing and emerging research directions include:

AlN composites doped with Y₂O₃ or rare earth oxides to enhance mechanical and moisture resistance.

Additive manufacturing (3D printing) of complex AlN-based insulating components.

Flexible AlN thin films for conformal coating of unusual geometries in next-gen electronics.

Co-firing with metal conductors to produce multilayered ceramic PCBs for harsh environments.

Furthermore, AlN is being explored for cryogenic insulation in quantum computing systems where low thermal expansion and electrical isolation are crucial.

- Challenges to Address

While the potential is significant, several challenges remain:

Cost: High-purity AlN and its processing methods (e.g., hot pressing) remain expensive.

Moisture Sensitivity: AlN can hydrolyze in humid conditions unless properly sealed or treated.

Machining Difficulty: Due to its hardness, AlN requires diamond tooling or advanced shaping techniques.

These challenges are being actively addressed through surface coatings, composite formulations, and process innovations.

Conclusion

Aluminum nitride is not merely a heat conductor or a ceramic insulator—it is one of the few materials that can reliably perform both roles in extreme conditions. Its ability to combine thermal management and electrical isolation under high temperatures makes it an indispensable material in the development of next-generation power systems, aerospace electronics, and energy infrastructure.

Leave a Reply