The Challenges and Technical Bottlenecks of Recrystallized Silicon Carbide: A Road to Breakthrough

In recent years, recrystallized silicon carbide (SiC) has gradually emerged as a key material in various high-end applications, thanks to its excellent high-temperature stability, corrosion resistance, and outstanding mechanical properties. However, despite its broad application prospects, the production and application of recrystallized silicon carbide still face several technical challenges and bottlenecks. This article delves into these challenges and explores how the industry is striving to overcome these technical obstacles to promote the further development of this material.

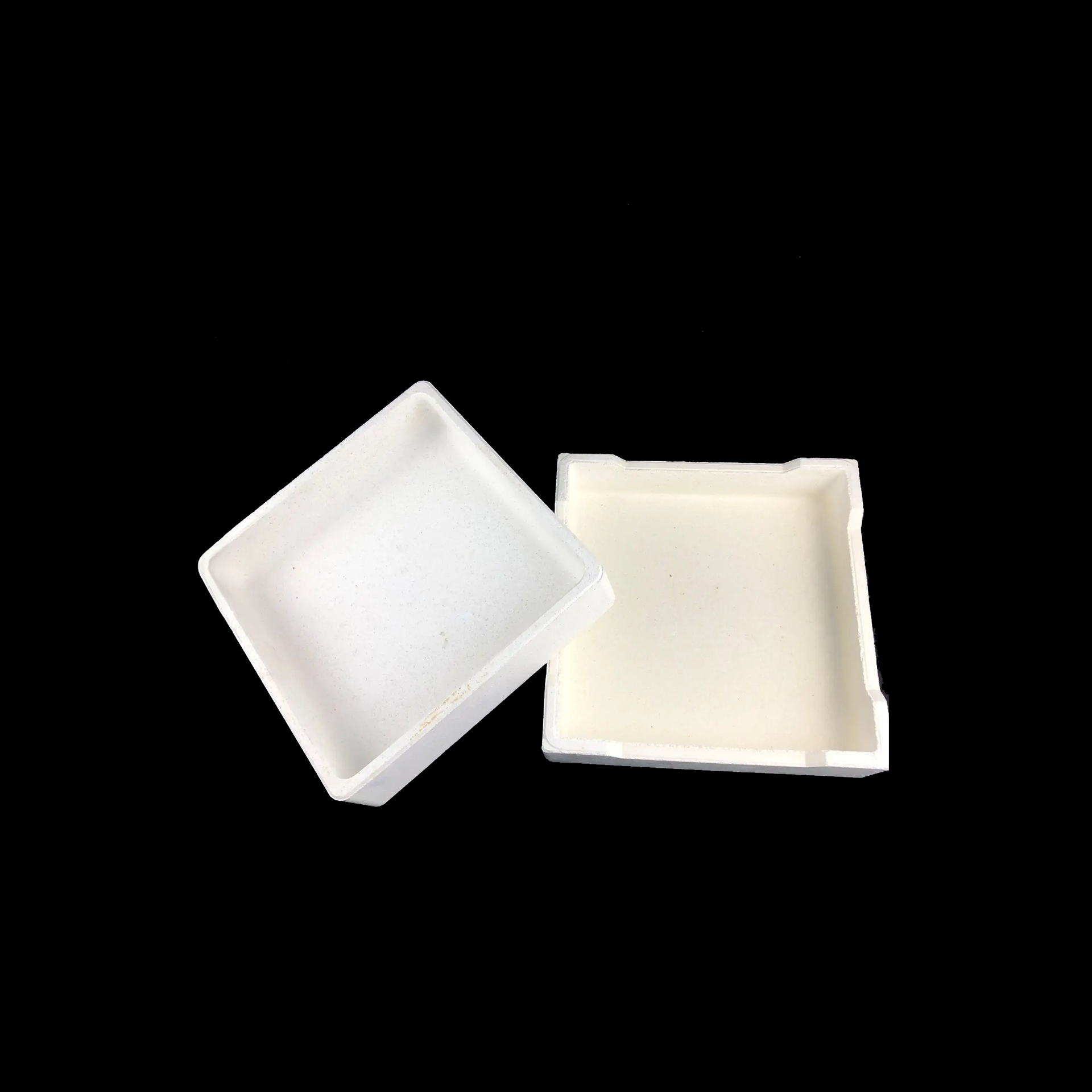

-

Manufacturing Challenges of Recrystallized Silicon Carbide: High Costs and Production Consistency

1.1 High Cost Issues

At present, the production of recrystallized silicon carbide remains a high-cost process. The production involves high-temperature sintering, which requires the use of high-purity raw materials and specialized equipment, leading to high production costs. This high cost limits the large-scale application of recrystallized silicon carbide in certain industries (e.g., consumer products and low-cost industrial goods).

Solutions:

- Raw Material Optimization: Reduce the cost of raw materials by developing cheaper alternatives and sources.

- Process Innovation: Optimize sintering processes, adopt more efficient equipment, and explore new reaction environments to shorten production cycles and reduce energy consumption.

1.2 Production Consistency and Quality Control

During the production of recrystallized silicon carbide, due to the material’s complex crystal structure and the need for precise control during the sintering process, there is significant variability in the final product’s quality. It is difficult to achieve consistent grain size, porosity, and mechanical properties, which affects the stability and reliability of the final products.

Solutions:

- Advanced Control Systems: Use real-time monitoring technology and automated control systems to precisely adjust parameters like temperature and pressure to ensure the stability of the production process.

- Refined Process Techniques: Optimize factors such as atmosphere control and sintering time to improve crystal uniformity and consistency.

-

Application Bottlenecks of Recrystallized Silicon Carbide: Applicability and Processing Difficulty

2.1 Processing Difficulty

Due to the hardness and brittleness of recrystallized silicon carbide, traditional machining methods (e.g., cutting, grinding, drilling) are difficult to apply. The material is prone to cracking, especially during high-precision machining, which can lead to processing failures. This poses a major challenge for the manufacturing of precision parts and complex shapes.

Solutions:

- Innovative Machining Technologies: Adopt advanced precision machining techniques such as laser processing and electrical discharge machining (EDM) to avoid cracking issues and achieve more complex geometries.

- Use of High-Performance Abrasives: Utilize more durable abrasives and tools to improve processing efficiency and quality.

2.2 Limited Application Fields

Although recrystallized silicon carbide excels in high-temperature, high-pressure, and high-strength environments, its brittleness limits its application in certain dynamic loading conditions. For example, in high-speed rotating mechanical parts or kinetic energy transmission systems, there is a higher risk of brittle fracture.

Solutions:

- Composite Material Design: Combine recrystallized silicon carbide with other materials (e.g., metals, ceramics) to form composite materials that improve toughness and impact resistance. For example, SiC-metal composites are increasingly being applied in aerospace.

- Microstructure Optimization: Enhance toughness and impact resistance by modifying the microstructure of recrystallized silicon carbide (e.g., grain size, porosity).

-

Environmental and Sustainability Issues

3.1 Environmental Impact of the Production Process

The production of recrystallized silicon carbide requires high-temperature and high-pressure conditions, consuming large amounts of energy, and potentially releasing harmful gases or waste in certain processes. As environmental regulations become stricter, the silicon carbide industry is facing increased pressure to meet higher environmental standards.

Solutions:

- Green Production Technologies: Research and apply low-temperature, low-energy consumption production methods, such as isostatic pressing sintering, to reduce energy consumption.

- Gas Recovery and Pollution Control: Develop gas recovery systems to reduce harmful emissions during production, ensuring compliance with environmental regulations.

3.2 Recyclability and Resource Utilization

Recrystallized silicon carbide is challenging to effectively recycle and reuse during its lifecycle. As the demand for this material grows, improving resource utilization and reducing waste has become a critical issue.

Solutions:

- Recycling Technology Development: Develop technologies for recycling recrystallized silicon carbide, allowing for the reuse of waste material and reducing reliance on raw materials.

- Circular Economy Model: Promote material recovery and closed-loop systems in the production process to minimize waste.

-

Future Outlook: Technological Innovation and Breakthroughs to Address Bottlenecks

Although there are several technical bottlenecks at present, the future prospects for recrystalliz silicon carbide remain vast. With continuous advancements in research and technology, we can expect breakthroughs in overcoming these challenges. The future may see:

- Lower Production Costs: As new synthetic methods and equipment are developed, the production cost of recrystalliz silicon carbide will gradually decrease, expanding its applications across more industries.

- Multifunctional Composites: By combining recrystalliz silicon carbide with other high-performance materials, it will demonstrate more diversified functions, meeting the demands of various industries.

- Environmental Sustainability: The application of green and environmentally friendly technologies will make the production of recrystallized silicon carbide more energy-efficient and eco-friendly, aligning with future sustainability goals.

Conclusion: Overcoming Challenges and Leading the Future

Despite the technical challenges that recrystalliz silicon carbide currently faces, these obstacles can be gradually overcome with technological progress and innovation. As an excellent high-performance material, recrystallized silicon carbide is poised to play an increasingly important role in high-end manufacturing, electronics, energy, aerospace, and many other industries. Overcoming its current challenges will not only bring new breakthroughs to materials science but also unlock vast potential for industrial applications in the future.

Leave a Reply