Maintenance and Care of Corundum-Mullite

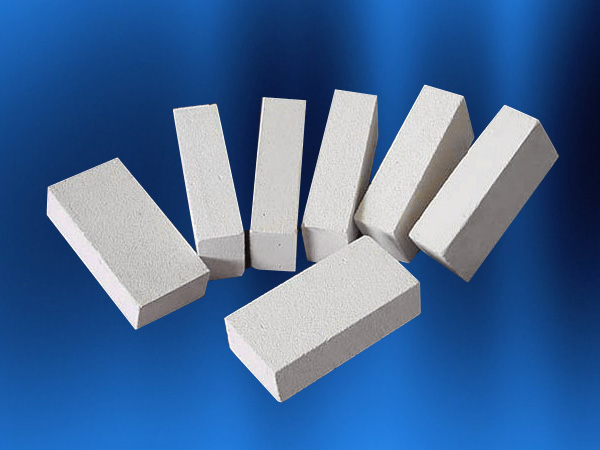

As an important refractory material widely used in metallurgy, ceramics, glass, and other high-temperature fields, corundum-mullite is favored for its excellent fire resistance and thermal shock resistance. However, appropriate maintenance and care during use are equally crucial. Effective maintenance not only extends the service life of corundum-mullite but also ensures the safety and efficiency of equipment and production processes. This article will explore various aspects of maintenance and care strategies for corundum-mullite.

1. Storage Conditions

Firstly, storage conditions are key factors influencing the performance of corundum-mullite. It should be stored in a dry, well-ventilated environment to avoid moisture and high temperatures, as moisture can lead to changes in the material’s physical and chemical properties. Additionally, it is essential to prevent contact with acidic or alkaline substances to avoid chemical reactions that may damage the material. Whenever possible, corundum-mullite should be placed on shelves a certain height off the ground to prevent water ingress and contamination from the floor.

2. Regular Inspections

To ensure the performance of corundum-mullite, regular inspections are necessary maintenance steps. During use, the appearance of the material should be regularly checked for possible cracks, spalling, or other signs of damage. Particularly in high-temperature conditions, the refractory performance of corundum-mullite may be affected; therefore, monitoring its structural integrity can help identify issues and take corrective actions promptly.

When inspecting, pay attention to the following aspects:

-

- Surface Condition: Check for cracks or discoloration.

- Dimensional Changes: Assess whether there are significant changes in the material’s dimensions, especially regarding thermal expansion at high temperatures.

- Connection Points: Examine the connection points between the material and the equipment to ensure that there are no looseness or detachment issues.

3. Cleaning and Maintenance

Cleaning is a vital aspect of maintaining the performance of corundum-mullite. During use, dirt, dust, and other impurities may accumulate on the surface of the material, potentially impacting its refractory and thermal conductivity properties. It is advisable to clean regularly using a soft brush or cloth, avoiding sharp objects that could scratch the surface.

When it comes to high-temperature equipment, cleaning should also consider the following points:

-

- High-Temperature Residues: After high-temperature operations, promptly clean any slag or solid residues that may form on the surface of the material to prevent long-term damage.

- Chemical Residues: If corundum-mullite comes into contact with chemicals, use appropriate cleaning agents for thorough cleaning to ensure that chemical residues do not affect the material’s properties.

4. Appropriate Operating Environment

To ensure the best performance of corundum-mullite, it is essential to choose an appropriate operating environment based on the material’s refractory characteristics. Although corundum-mullite is highly resistant to heat, it may experience aging or failure in extreme temperatures or corrosive environments. Therefore, operations should avoid sudden temperature changes to reduce the impact of thermal shock on the material.

When designing production equipment, it is crucial to consider the thermal properties of corundum-mullite and plan its layout and usage accordingly to ensure optimal operating conditions. For instance, in the metallurgy industry, the design of furnaces should account for the thermal expansion and contraction characteristics of corundum-mullite, preventing stress concentration.

5. Professional Training and Guidance

Companies should regularly conduct professional training for operators to ensure they understand the characteristics of corundum-mullite and its maintenance methods. Through training, employees can master effective operational skills and maintenance procedures, ensuring normal equipment operation and optimal material performance. Additionally, establishing detailed maintenance records is an important aspect of improving material management; by documenting maintenance history, it is possible to analyze material usage patterns and formulate appropriate maintenance plans.

6. Timely Replacement and Renewal

Despite the excellent refractory performance of corundum-mullite, it may still undergo aging or damage after prolonged use. Therefore, companies should develop reasonable replacement and renewal plans based on the material’s usage conditions and performance monitoring results. For severely damaged materials, timely replacement is necessary to prevent production disruptions.

Conclusion

In summary, the maintenance and care of corundum-mullite are not merely about extending the material’s service life but are also crucial for ensuring production safety and efficiency. Through good storage conditions, regular inspections, effective cleaning, appropriate operating environments, professional training, and timely replacements, companies can ensure the stability and reliability of corundum-mullite in high-temperature environments. These maintenance measures not only enhance the material’s economic benefits but also contribute to improving overall production efficiency, bringing greater value to enterprises.

Leave a Reply